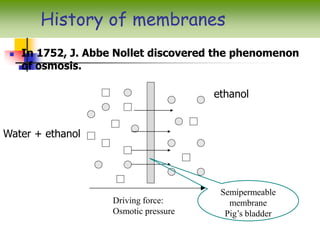

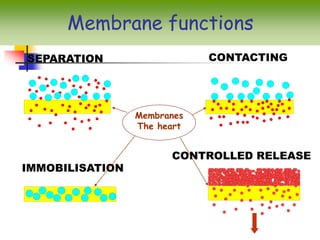

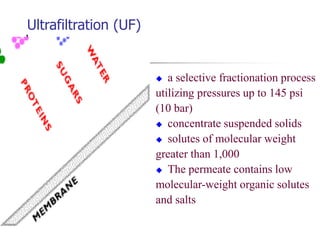

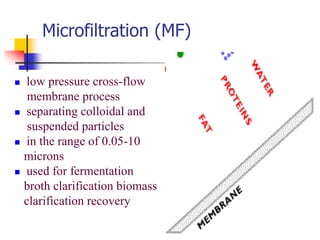

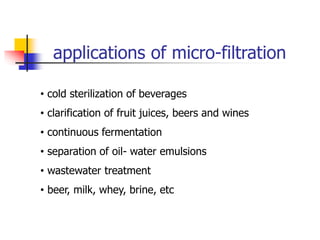

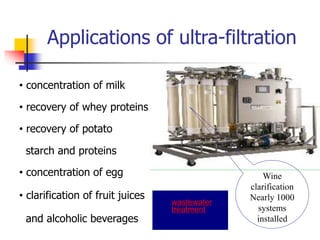

The document discusses the history and types of membrane processing, including osmosis and various filtration methods such as microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. It highlights their applications in industries like beverages, wastewater treatment, and desalination, emphasizing the advantages of energy efficiency and higher product quality. However, it also addresses limitations like membrane fouling and the need for extensive pretreatment.