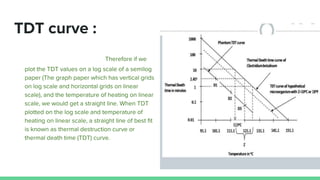

Thermal death time (TDT) is defined as the heating duration required to eliminate a specified number of microorganisms at a set temperature, showing a logarithmic relationship with temperature. By graphing TDT values on a logarithmic scale against temperature, a TDT curve is generated that aids in determining TDT for microorganisms at unknown temperatures. This concept is crucial in food safety, cosmetics, and pharmaceuticals, ensuring effective sterilization processes.