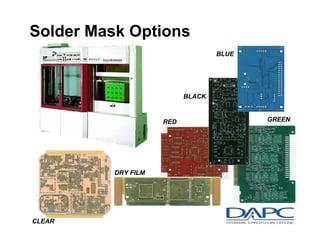

This document provides an overview of Dynamic & Proto Circuits Inc.'s facilities and manufacturing capabilities. It summarizes their 54,000 square foot facility, multilayer PCB process, equipment including strip-etch-strip lines, automated optical inspection, drilling machines, via plugging machines, soldermask coaters, HASL machines, IST testers, and lists their substrate and high frequency materials. It also lists their North American top tier customers and encourages the reader to have DAPC work on their projects.