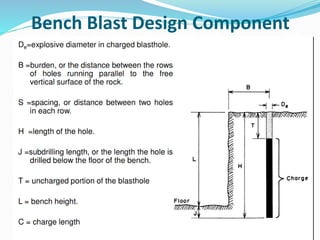

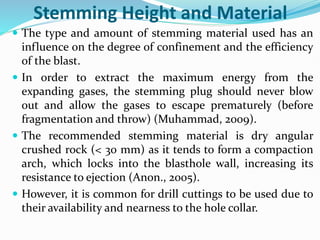

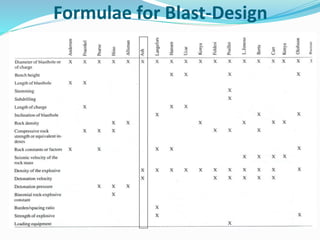

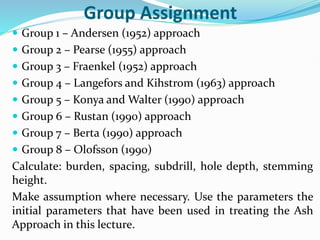

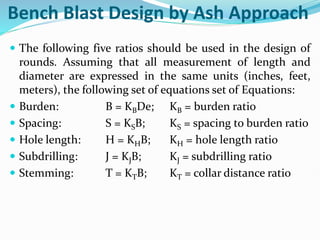

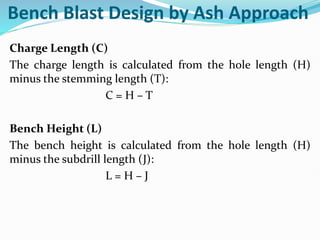

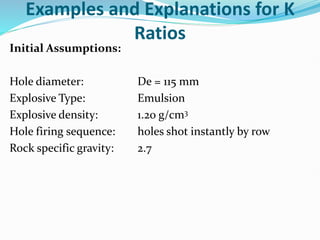

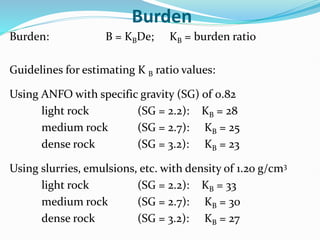

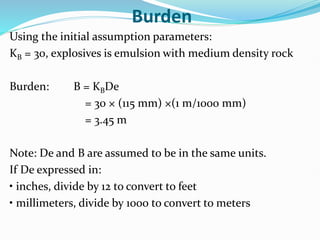

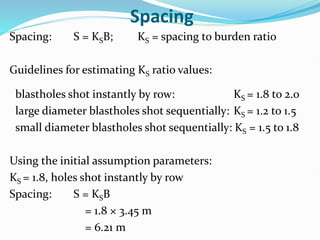

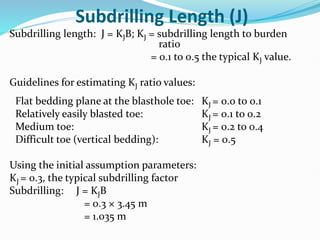

The document discusses factors that influence blast design and describes the various components of bench blast design. It provides background on how the blast design must balance parameters to achieve desired fragmentation. The factors affecting blast design are classified as uncontrollable geological variables and controllable variables like hole diameter, burden, spacing, stemming, and firing system. Formulas are provided for calculating the values of bench blast design components like burden, spacing, subdrilling, hole depth, and stemming height using the Ash approach. Examples are worked out using initial assumptions of a 115mm hole diameter, emulsion explosive, and medium rock density. The document concludes with discussing powder factor calculation and the basic steps for successful blast design.