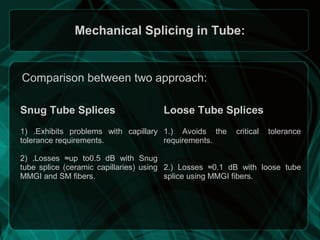

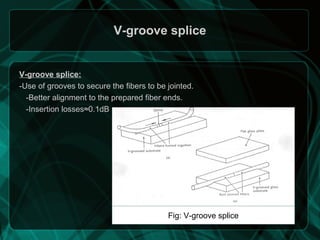

Fiber optic splicing is crucial for joining fiber optic cables, especially when extending cable length is necessary. Two primary methods identified are mechanical splicing, which aligns fibers without heat, typically resulting in a loss of 0.3 dB, and fusion splicing, which uses heat for lower loss connections (0.1 dB). Mechanical splicing can be performed through various techniques, offering advantages such as semi-permanence and ease of field implementation, but has higher losses compared to fusion splicing.