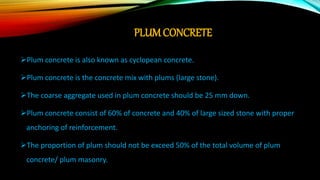

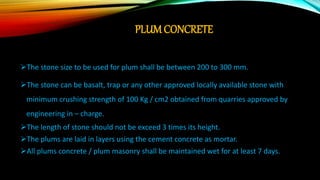

The document discusses concrete and specifically plum concrete, which is a mixture of concrete and large stones used for various construction purposes, particularly where faster completion and lower costs are needed. It includes comparisons of compressive strength between ordinary and plum concrete, indicating that ordinary concrete has higher strength. Additionally, the document highlights the advantages of concrete as a versatile building material compared to others, with lower CO2 emissions during production.