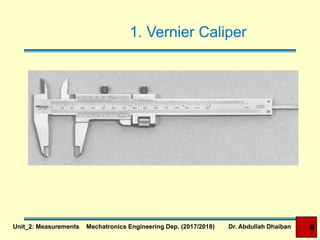

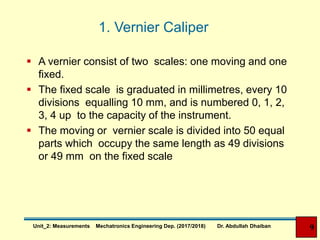

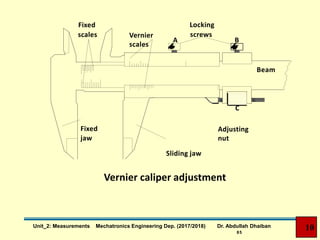

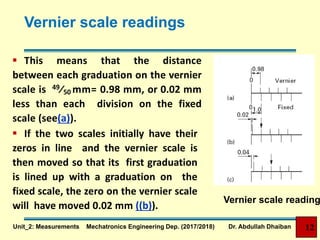

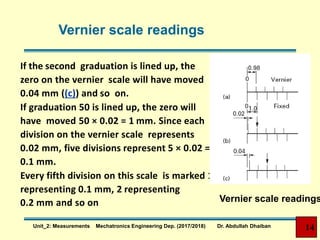

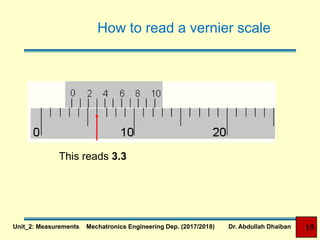

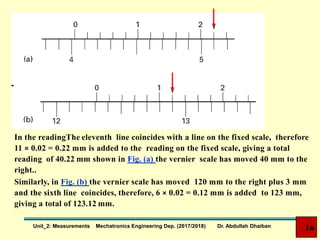

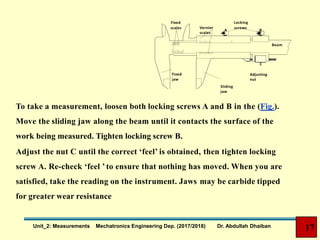

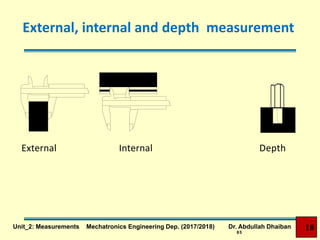

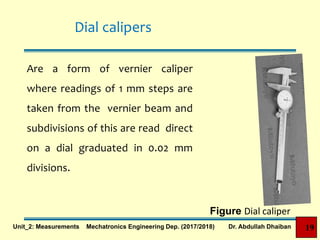

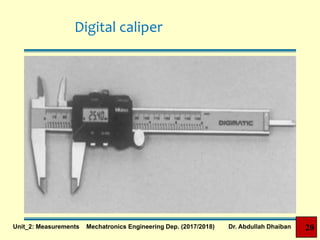

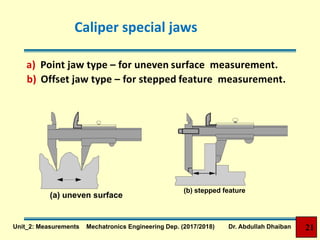

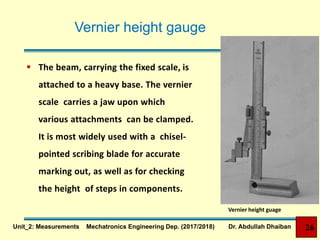

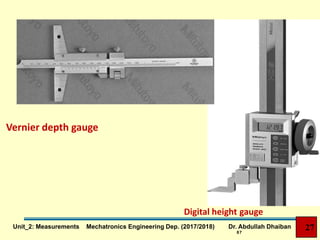

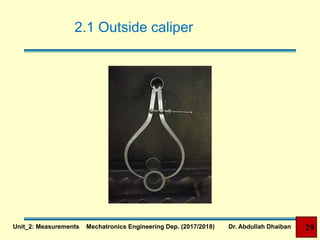

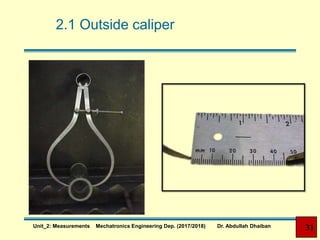

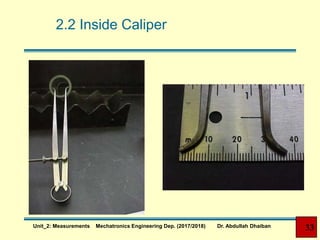

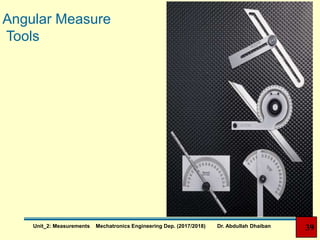

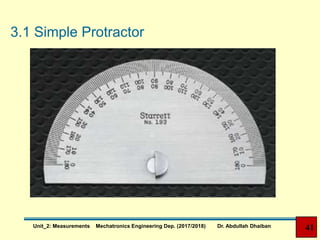

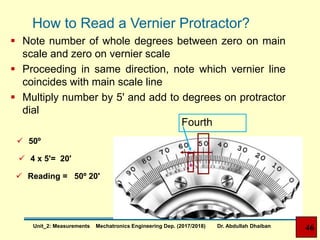

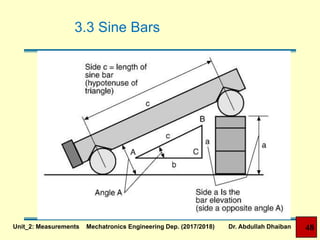

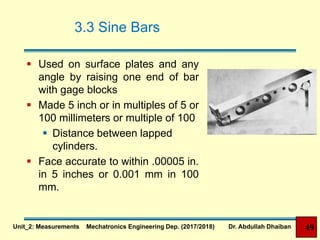

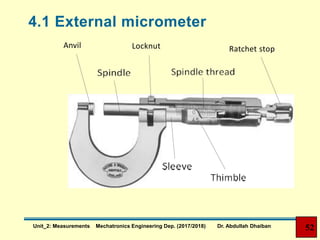

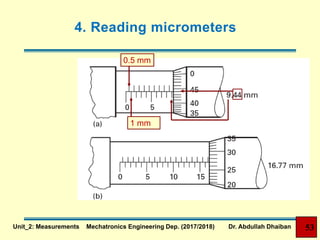

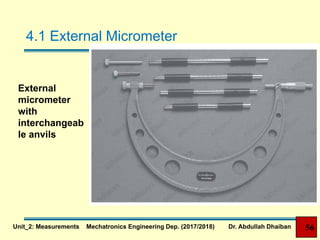

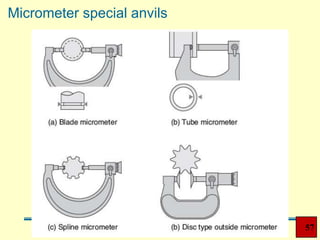

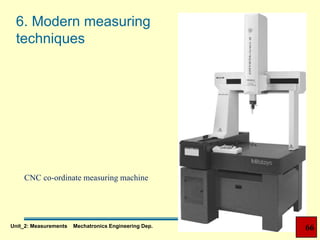

The document covers the principles and tools of measurement in engineering, emphasizing the importance of accurate measuring instruments for production and machining operations. It classifies measuring instruments into direct and indirect types, detailing various tools such as calipers, micrometers, and protractors for measuring dimensions, angles, and surface attributes. Additionally, it provides guidance on using specific instruments like the vernier caliper and the sine bar, ensuring precise readings in engineering applications.