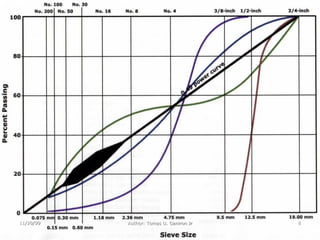

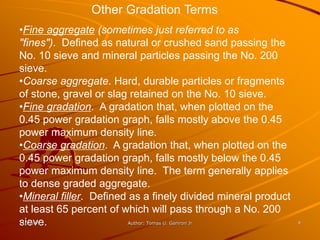

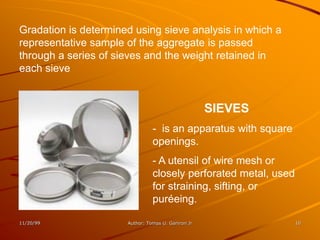

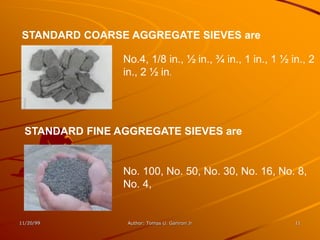

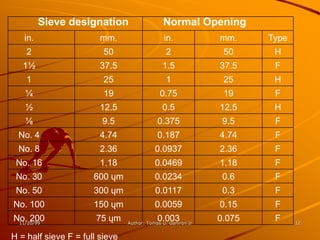

The document discusses various properties of aggregates that are important for construction materials. It describes how the modulus of elasticity and strength of aggregates can affect the properties of concrete. It also discusses how the gradation, or particle size distribution, of an aggregate impacts qualities like stiffness, stability, durability and strength. Sieve analysis is used to determine the gradation of an aggregate sample by passing it through a series of sieves and measuring the material retained on each sieve.