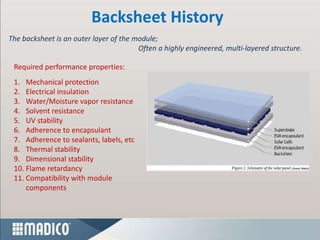

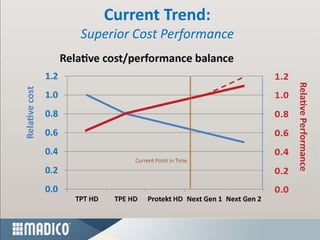

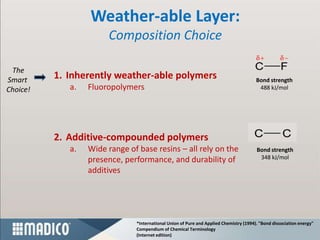

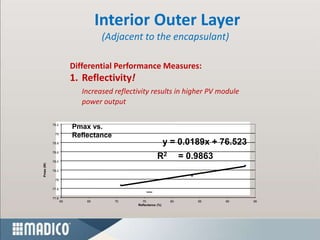

The document discusses the evolution and current trends in backsheet design for photovoltaic modules, focusing on the need for high-performance materials that provide mechanical protection, electrical insulation, and moisture resistance. Key trends include the use of innovative materials, adhesive-less construction, and the design of backsheets that enhance module efficiency and reflectivity. The presentation concludes with a call for specifically engineered films to replace traditional materials, promoting a greener manufacturing process.