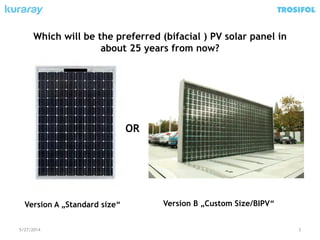

The document discusses challenges for glass and encapsulation in bifacial BIPV modules. It notes that bifacial modules require double glass laminates for the rear-facing solar cells. Thin float glass alone may not meet regulations for facade/roof glazing due to limited strength as laminated glass. Safety performance of common PV encapsulants like EVA and TPO are insufficient for laminated safety glass standards, while PVB, ionomer and TPU encapsulants can meet these standards, especially when combined with heat-strengthened or tempered glass. Future BIPV market development may focus on glass and encapsulant materials that best fulfill glazing safety and security performance requirements.