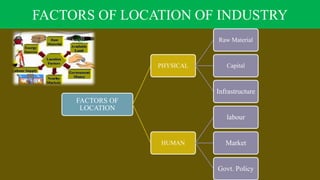

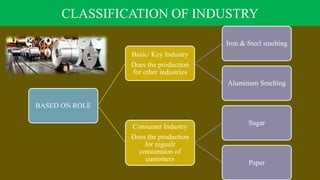

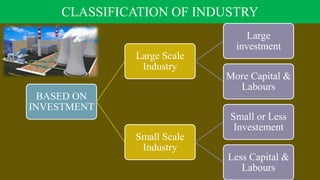

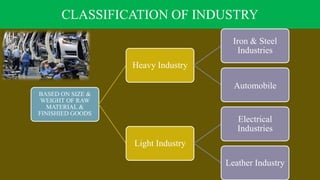

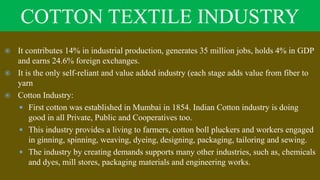

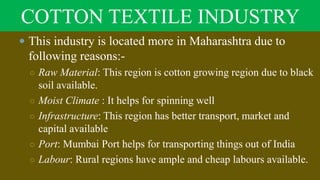

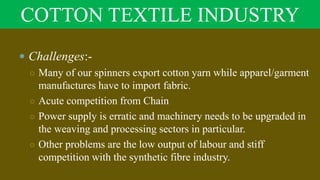

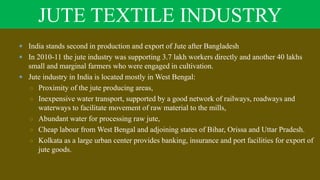

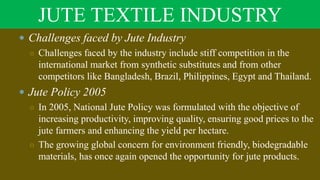

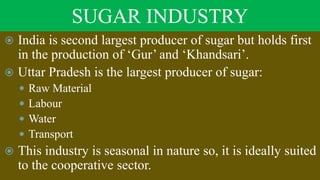

This document provides information on various manufacturing industries in India. It discusses key industries like cotton, jute, sugar, iron and steel, aluminum, chemicals, fertilizers, cement, automobile and the environmental pollution caused by industries. It highlights the importance of manufacturing for the Indian economy and employment. Location factors, challenges faced and contributions of different industries are summarized. Control measures to minimize environmental degradation from industries are also mentioned.