1. Manufacturing involves processing raw materials into finished goods in large quantities. It is considered important for development by providing jobs, modernizing agriculture, reducing poverty and regional disparities.

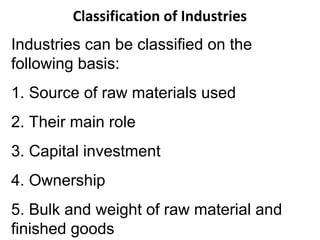

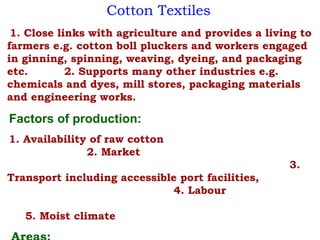

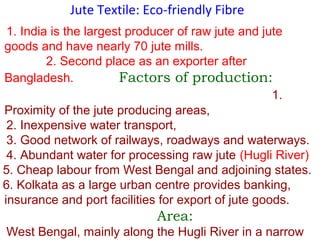

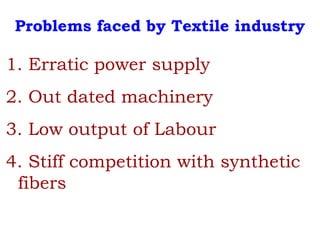

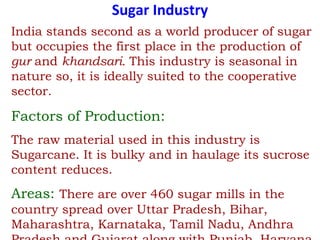

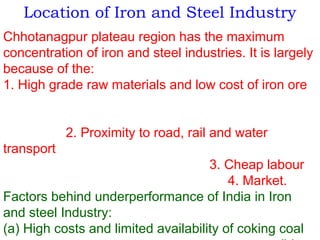

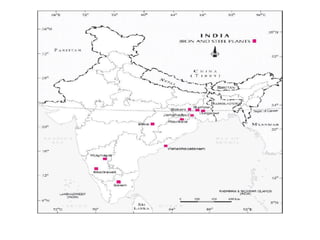

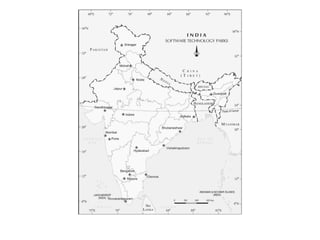

2. Industries are classified based on raw materials, role, capital, ownership and material properties. Textiles, sugar, iron and steel, chemicals, cement, automobiles and electronics are some important industries in India.

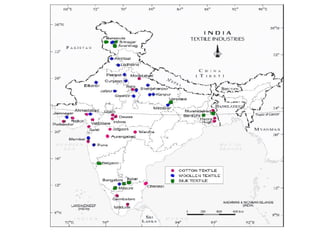

3. Location of industries depends on availability of raw materials, labor, markets, infrastructure and transportation. Pollution from industries harms the environment and controlling measures include emissions filters, reuse of water, and treatment of effluents.