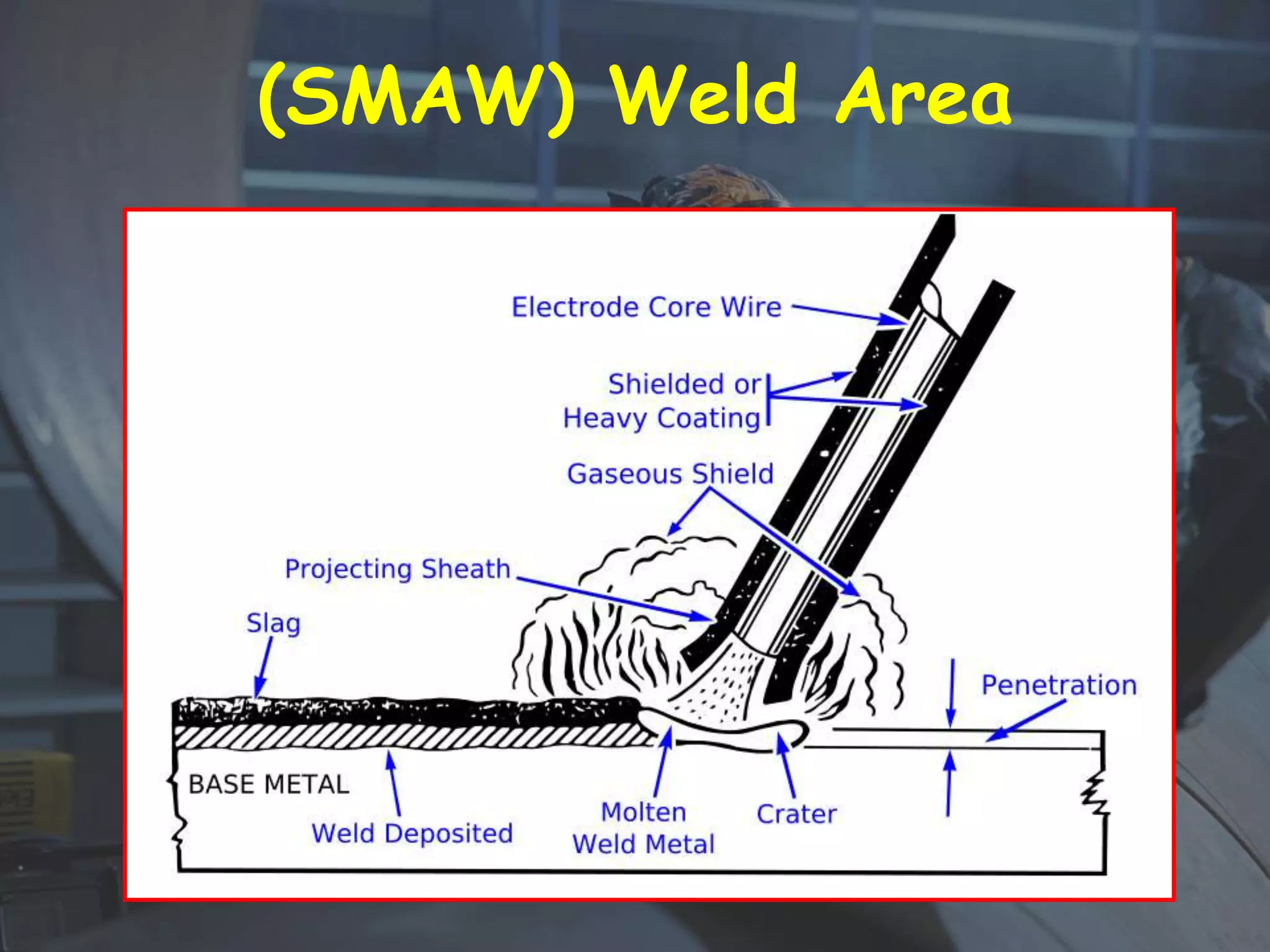

Shielded metal arc welding (SMAW), also known as stick welding, uses a consumable electrode coated in flux to lay the weld between metal workpieces. An electric arc forms between the electrode and workpiece, which melts the metals and causes droplets from the electrode to join in a weld pool. As the electrode melts, the flux shields the weld area from oxygen and other gases, and produces slag to cover the weld as it solidifies and protects it. SMAW equipment consists of a welding power supply connected by cables to an electrode holder. Proper safety equipment like a welding mask and gloves must be worn to protect from burns, sparks, radiation, and inhalation of dangerous fumes