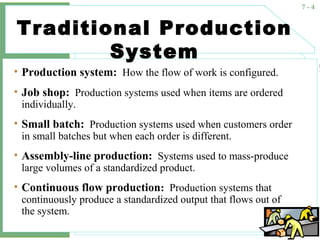

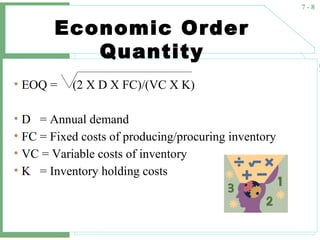

This document discusses key concepts related to operations management. It covers topics such as operations, productivity, different types of production systems, new production technologies like flexible production and mass customization, inventory management strategies like just-in-time and economic order quantity, and supply chain management. The document provides definitions and explanations of these important operations management terms.