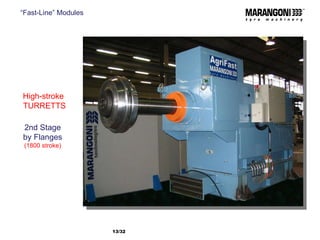

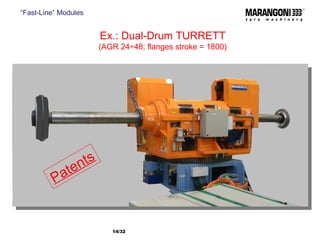

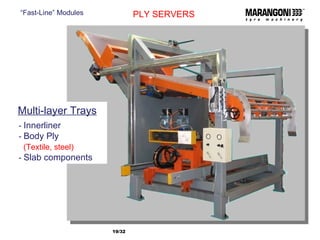

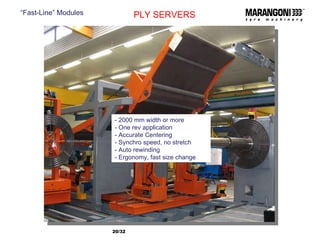

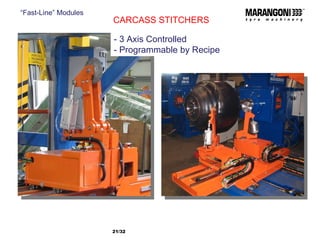

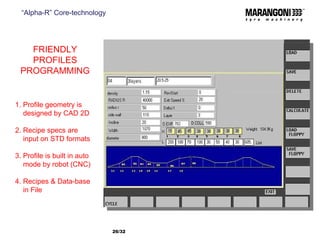

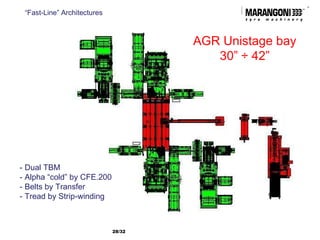

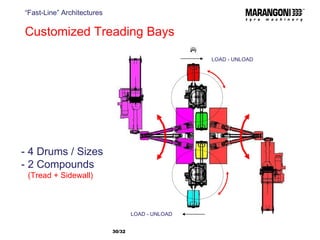

The document discusses Marangoni's state-of-the-art tire building machinery for large and very large tires. It describes their Fast-line tooling and modules that provide high quality, precision, flexibility and automation for tire sizes up to 63 inches. It also details their Alpha-R core technology for generating tire components through strip winding, including ribbon extruders and a strip applicator robot. Fast-line architectures allow for customized tire building bays using these technologies.