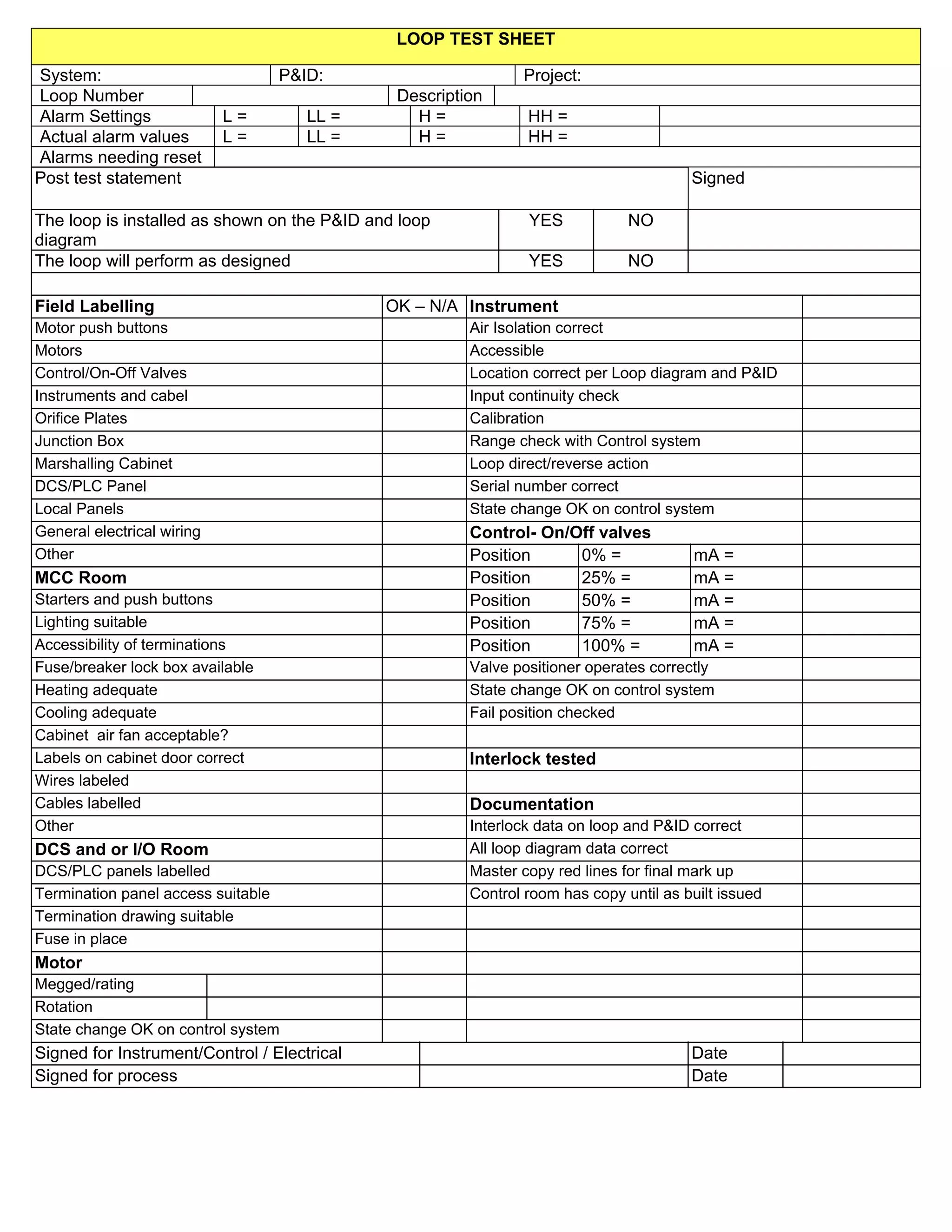

This document is a loop test sheet used to verify that a process loop is installed correctly and functioning as designed. It contains sections to record alarm settings, actual measured values, any alarms needing reset, and a signed statement about the loop's performance. The sheet also includes checkboxes to confirm that field labeling, instruments, valves, cabling, and electrical wiring for the loop meet design specifications.