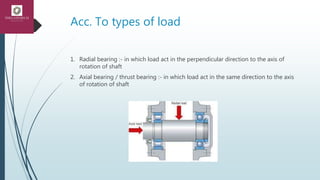

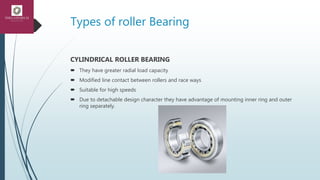

The document provides an overview of rolling contact bearings, categorizing them into sliding contact and rolling contact bearings, with a focus on the latter which includes various types such as ball and roller bearings. It explains the structure and functionality of these bearings, including their applications based on load types and bearing designs. Various types of rolling contact bearings, such as cylindrical, spherical, and needle roller bearings, are detailed, highlighting their specific characteristics and uses.