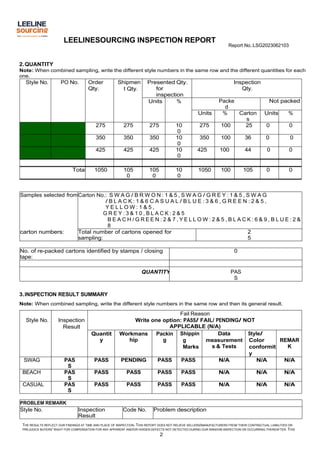

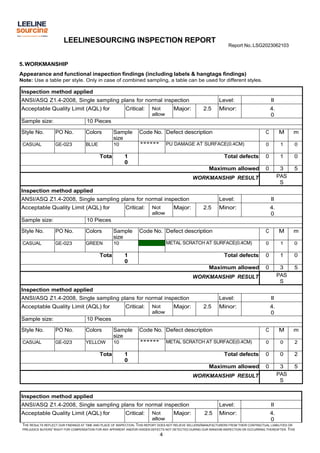

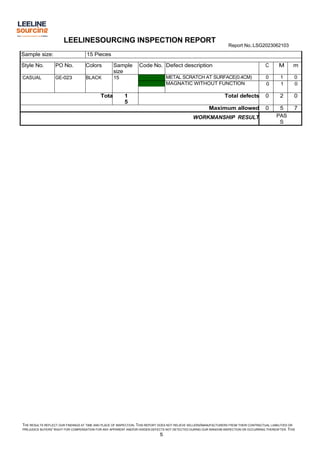

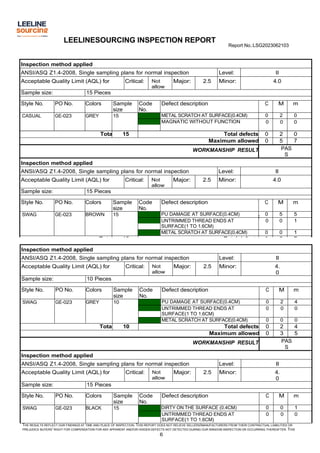

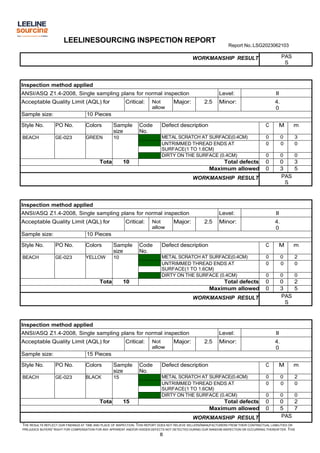

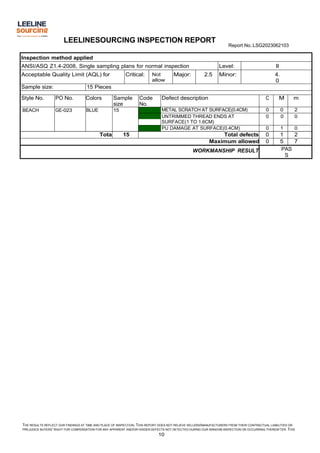

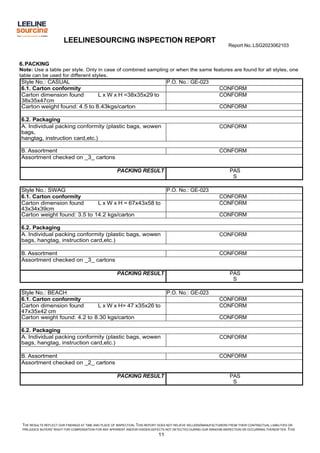

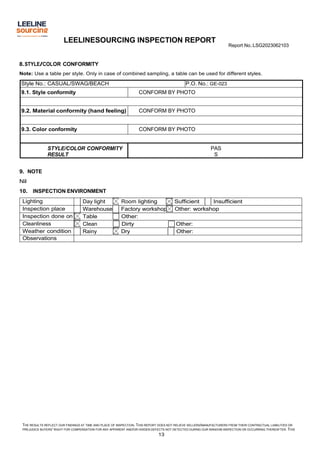

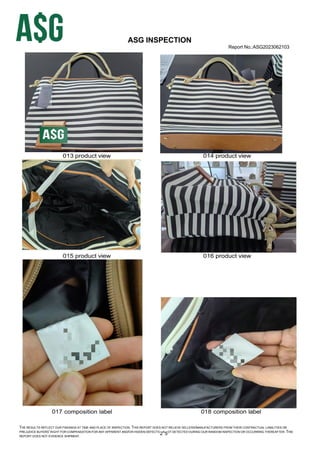

This inspection report provides the results of an inspection of various styles of leather goods. The styles inspected include SWAG, BEACH, and CASUAL in different colors. The inspection found minor defects like scratches and dirt on some samples but overall quality was found to be acceptable. One style called SWAG had a material surface damage issue and inspection of that style was pending repair by the factory. The report provides details of the inspection process, criteria, findings for each style and color, and determines that the workmanship for all styles passed except for SWAG which was pending repair.