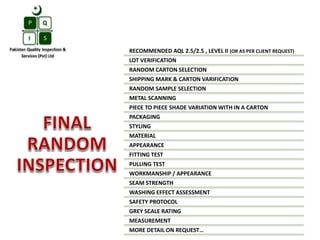

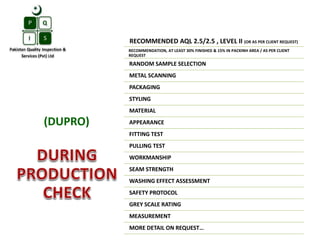

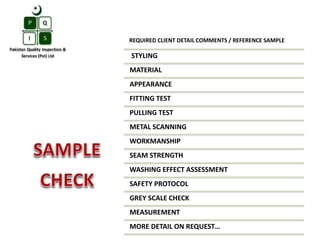

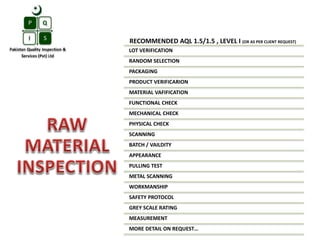

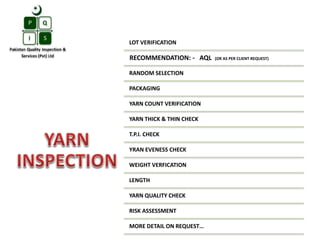

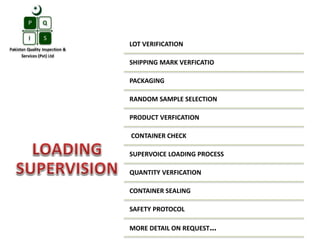

This document outlines inspection procedures for various stages of garment production including fabric inspection, sewing inspections, washing processes, finishing inspections and packaging inspections. It recommends inspection levels and sample sizes at each stage to check for quality, safety and compliance. Random sampling is recommended at multiple points to verify shipping marks, cartons, materials, workmanship, washing effects and measurements.