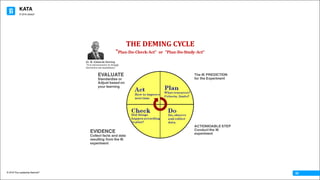

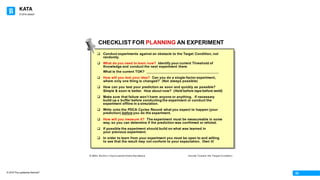

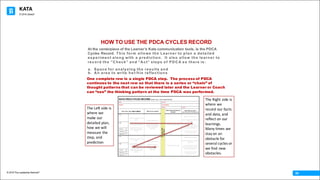

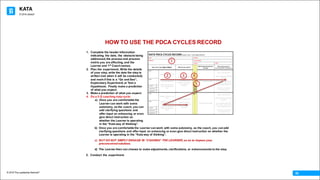

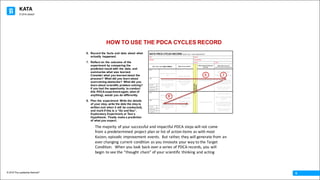

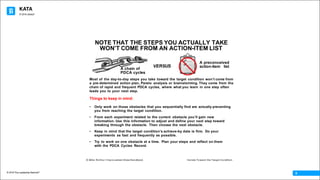

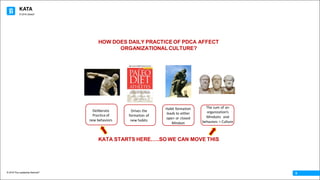

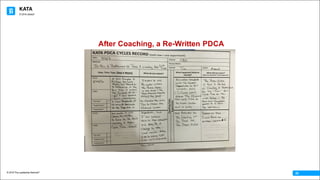

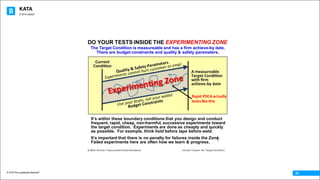

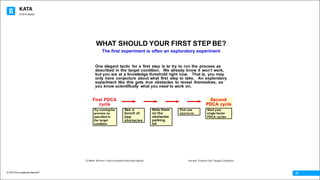

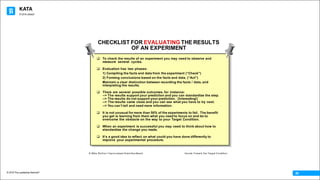

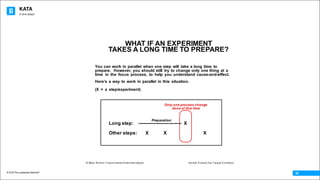

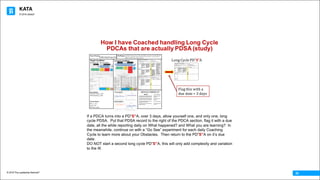

The document discusses the Toyota Kata method of process improvement using Plan-Do-Check-Act (PDCA) cycles. It provides guidance on how to effectively use a PDCA Cycles Record to plan and document experiments toward a target condition. Key points include planning experiments to address obstacles, making predictions, collecting data, reflecting on learnings, and using insights from one cycle to plan the next step. Conducting frequent, rapid, low-risk experiments in this scientific manner can help drive organizational cultural change over time.