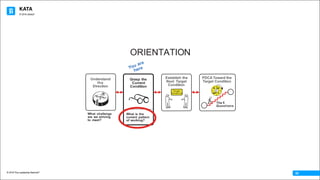

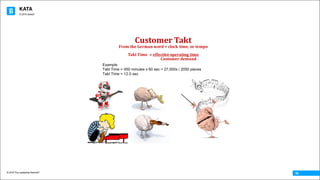

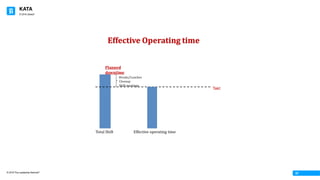

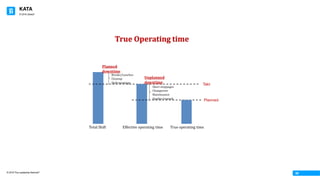

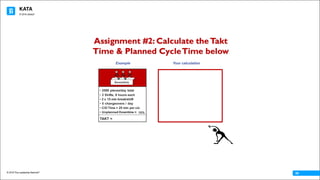

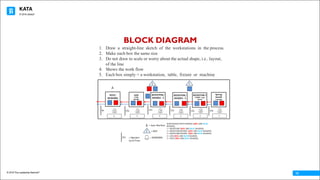

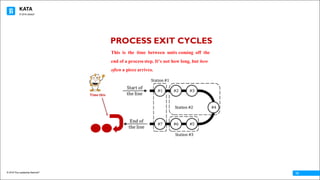

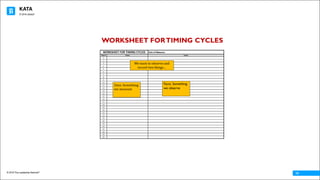

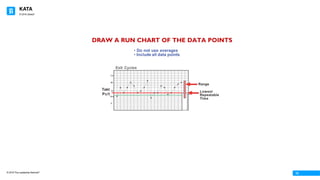

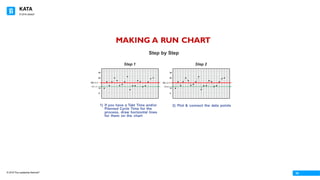

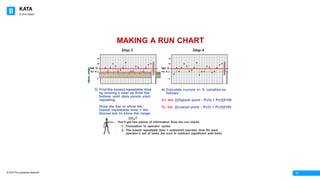

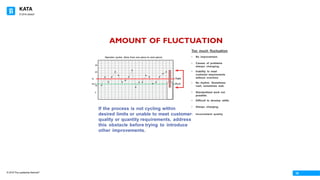

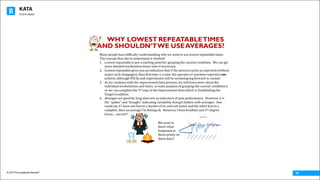

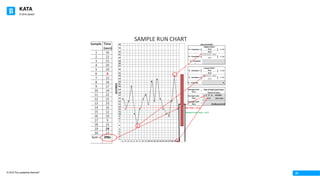

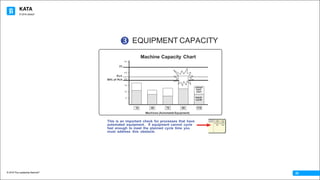

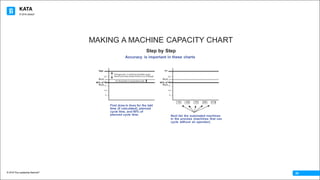

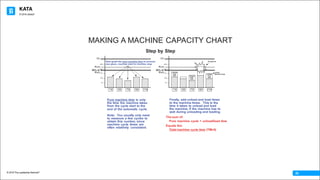

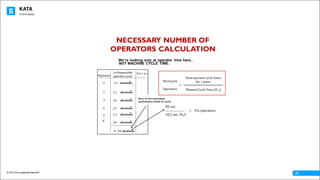

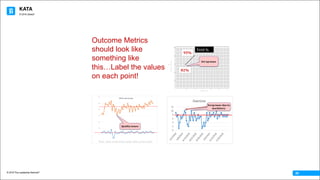

This document provides guidance on using the Toyota Kata approach to continuously improve processes. It discusses key steps in grasping the current condition including drawing a block diagram of the process flow, timing exit cycles at each workstation, and analyzing equipment capacity. The number of necessary operators is calculated by summing the lowest repeatable times for each workstation and dividing by the planned cycle time. Outcome metrics like output per shift should be graphed to understand performance. The overall goal is to thoroughly understand the existing process before establishing new targets for improvement.