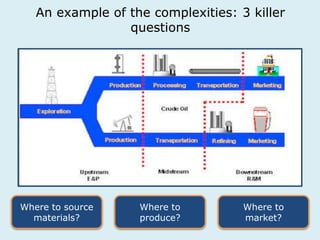

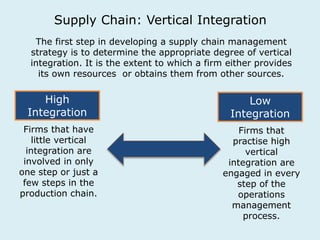

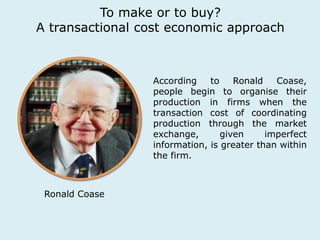

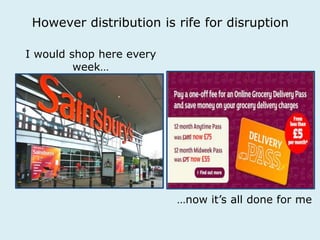

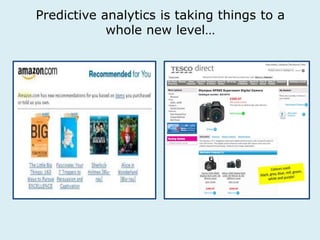

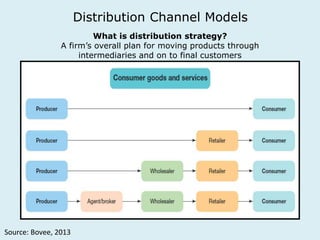

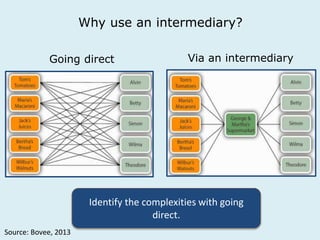

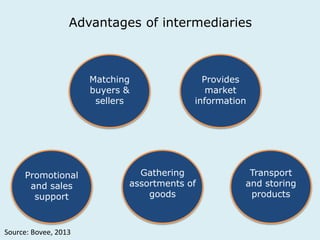

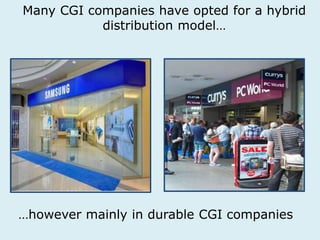

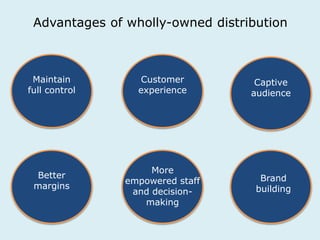

This document discusses strategies for global supply chains and distribution in the consumer goods industry. It begins by outlining the complexity of operating globally at scale and the strategic issues around supply chain management. It then evaluates the pros and cons of vertical integration and different distribution approaches. Various distribution channel models are presented and the advantages of intermediaries and wholly owned distribution are discussed. Technological advancements are changing the nature of distribution by enabling new predictive and direct models.