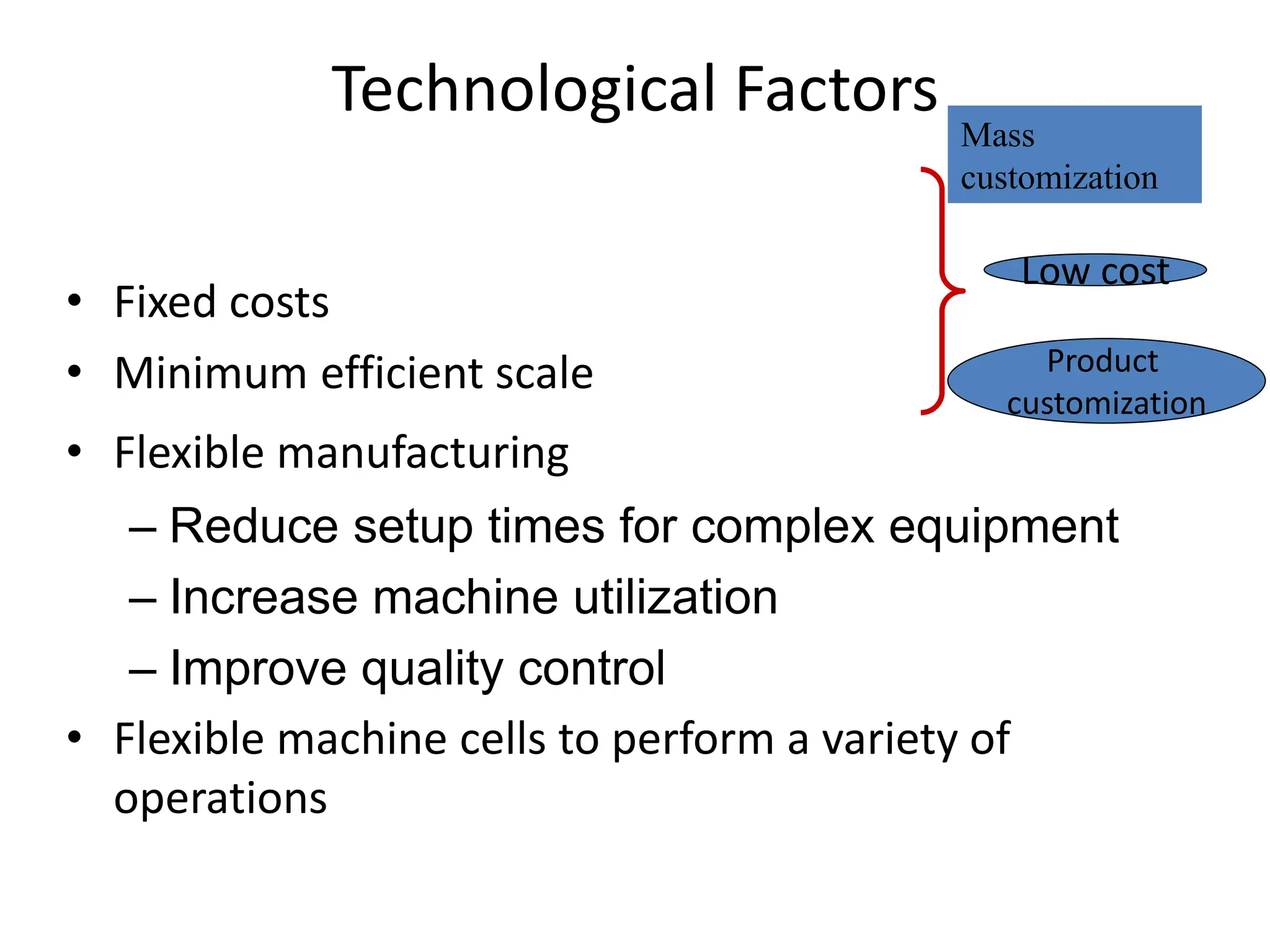

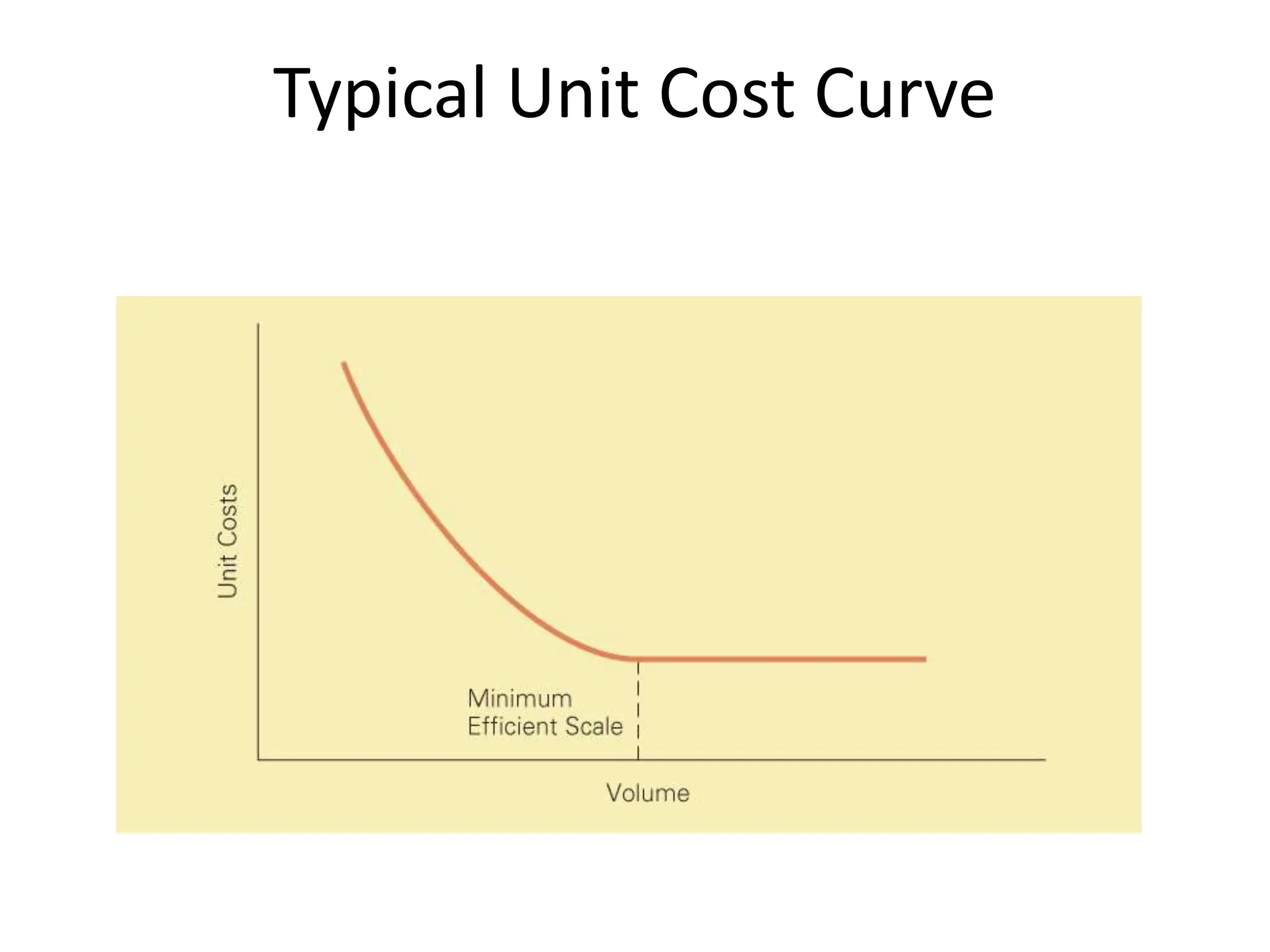

Microsoft decided to outsource production of the X-Box console to Flextronics for four reasons: Flextronics had supply chain control through an industrial park strategy; a global presence; used web-based information systems; and Microsoft trusted them. As trade barriers fall, firms must decide where to locate production, whether to own foreign sites, and how to manage globally dispersed supply chains and logistics. Production and logistics aim to lower costs and improve quality through strategies like total quality management and Six Sigma. Location decisions consider country, technological, and product factors to determine a centralized or decentralized production strategy.