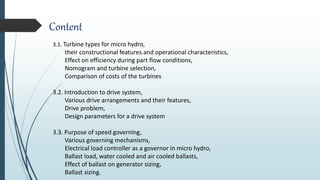

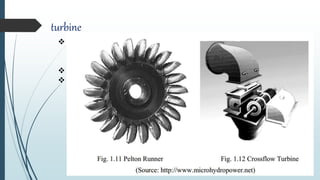

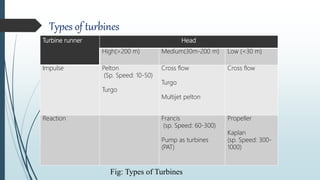

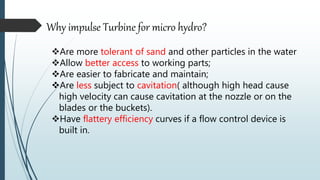

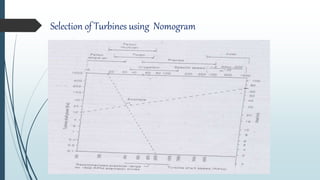

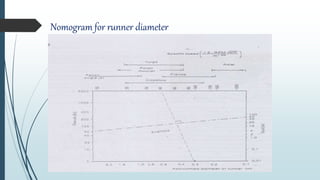

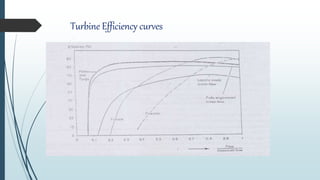

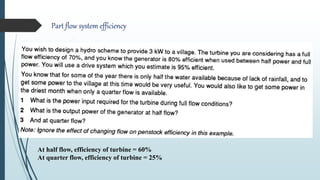

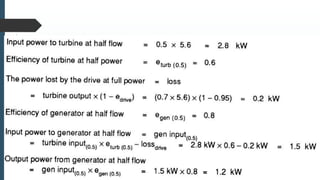

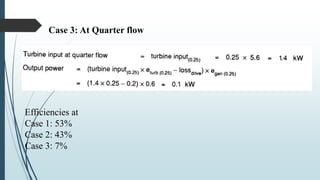

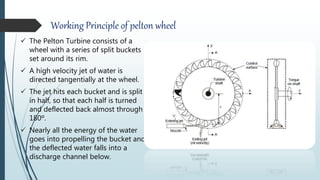

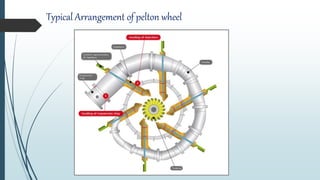

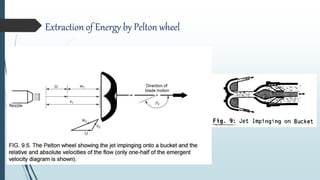

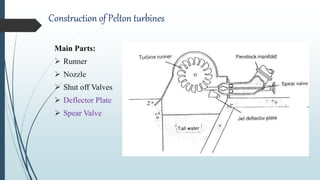

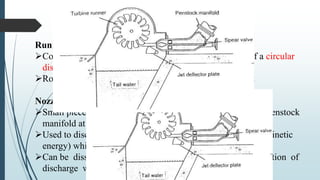

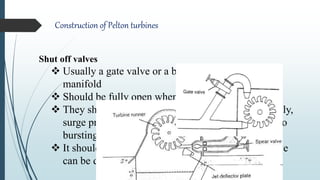

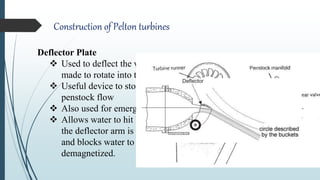

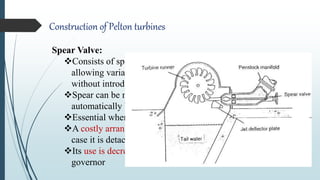

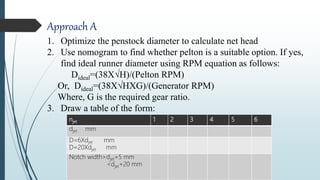

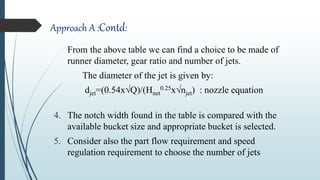

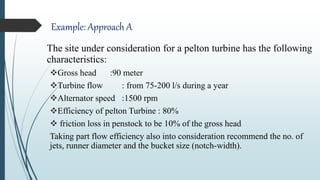

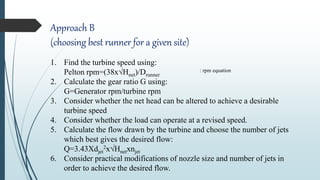

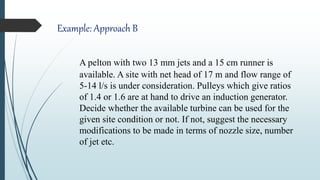

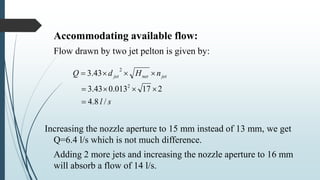

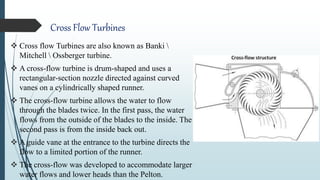

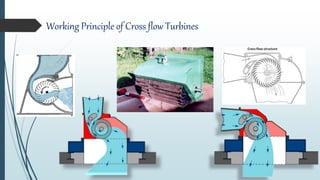

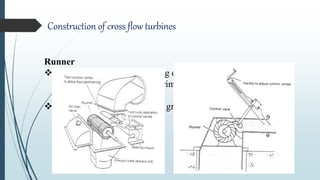

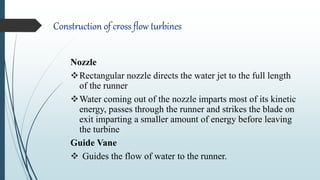

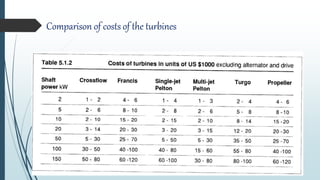

This document discusses different types of turbines used in micro hydro power systems, including their constructional features and operational characteristics. It covers impulse turbines like Pelton and Turgo turbines that are suitable for higher heads. It also discusses reaction turbines like cross-flow turbines that are used in lower head applications. The document provides details on selecting the appropriate turbine type using nomograms. It describes drive systems and speed governors. It also discusses part-flow efficiency and methods for sizing turbines based on site characteristics.