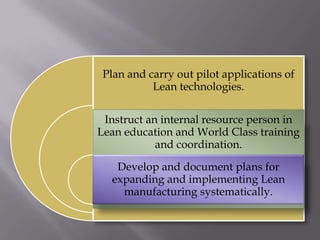

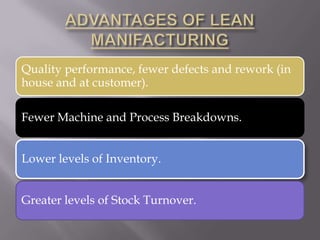

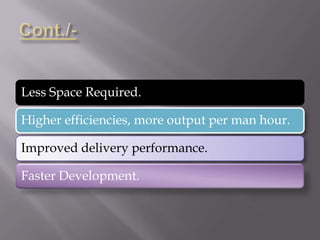

Lean manufacturing is a system originally developed by Toyota that aims to eliminate waste from the manufacturing process. It focuses on delivering exactly what customers want by improving productivity, quality, and innovation while reducing waste like excess inventory, transport, and defects. Benefits include improved customer service, productivity, quality, lead times, stock turns, and profits as well as higher employee morale.