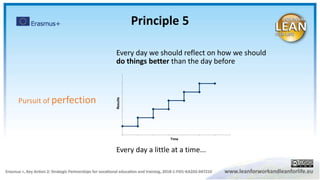

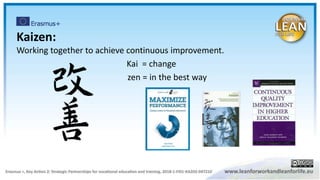

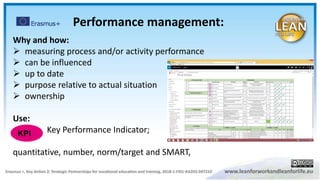

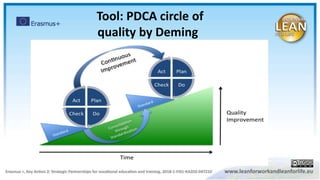

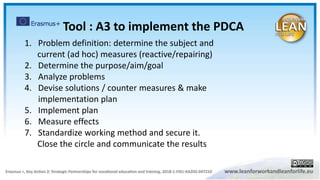

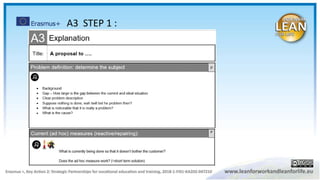

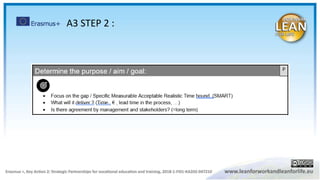

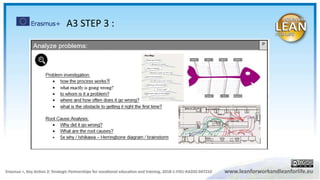

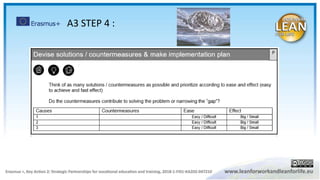

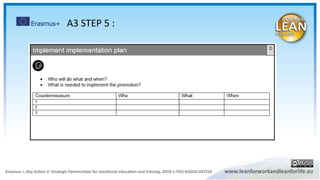

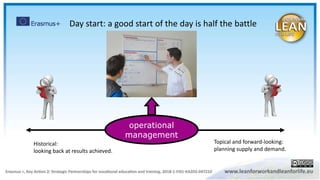

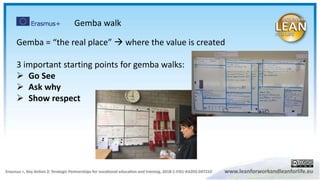

This document provides an overview of the fifth principle of Lean training - pursuing perfection. It discusses using tools like PDCA (plan-do-check-act), KPIs (key performance indicators), A3 problem solving reports, and visual management boards to continuously improve processes. The goal is to reflect daily on how to improve and make small changes over time through approaches like kaizen, or continuous improvement. Hoshin Kanri is also introduced as a way to deploy policies and align goals throughout an organization. Methods like gemba walks, day starts, and board management can be used to monitor progress and identify areas for further improvement.