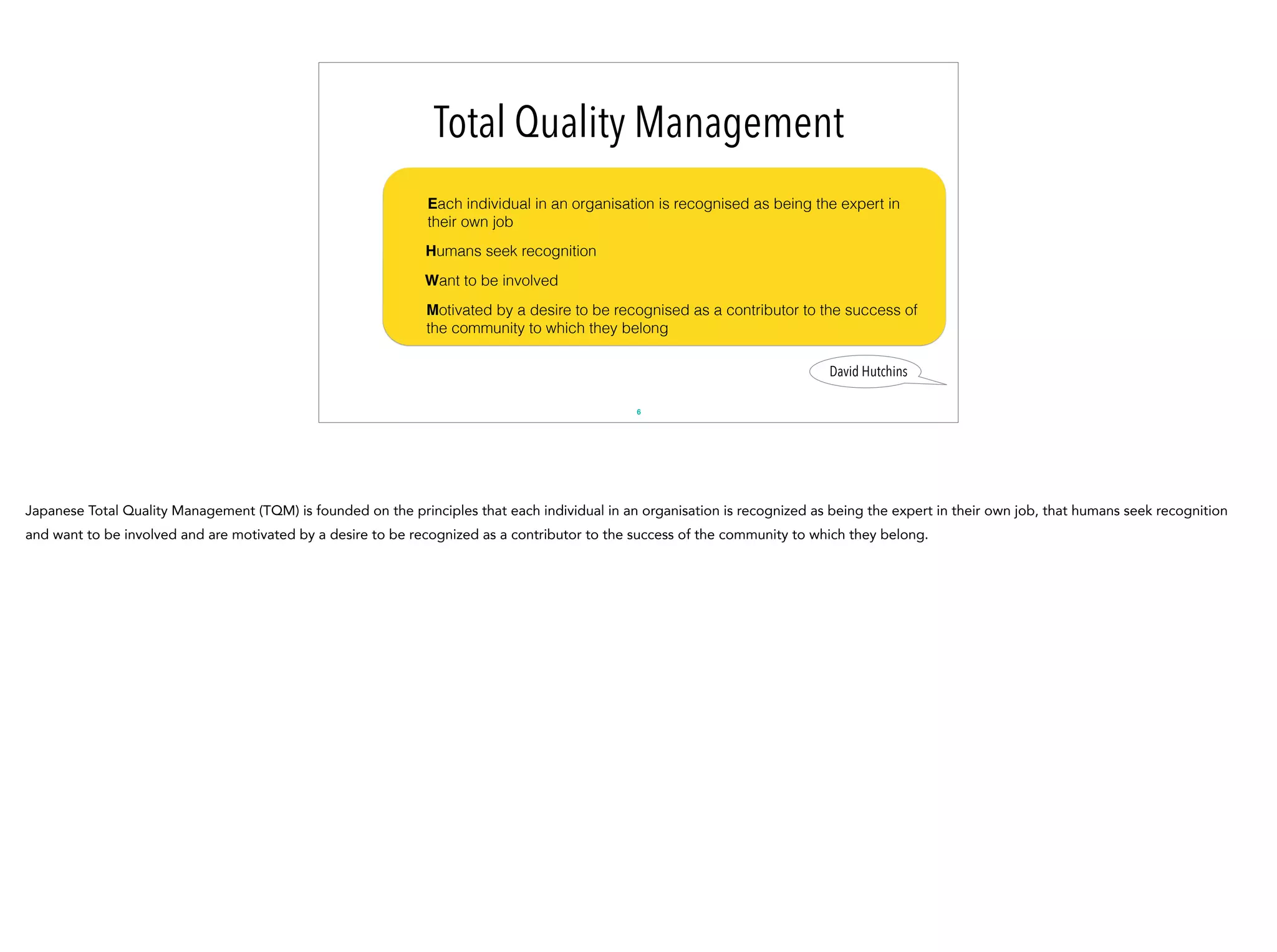

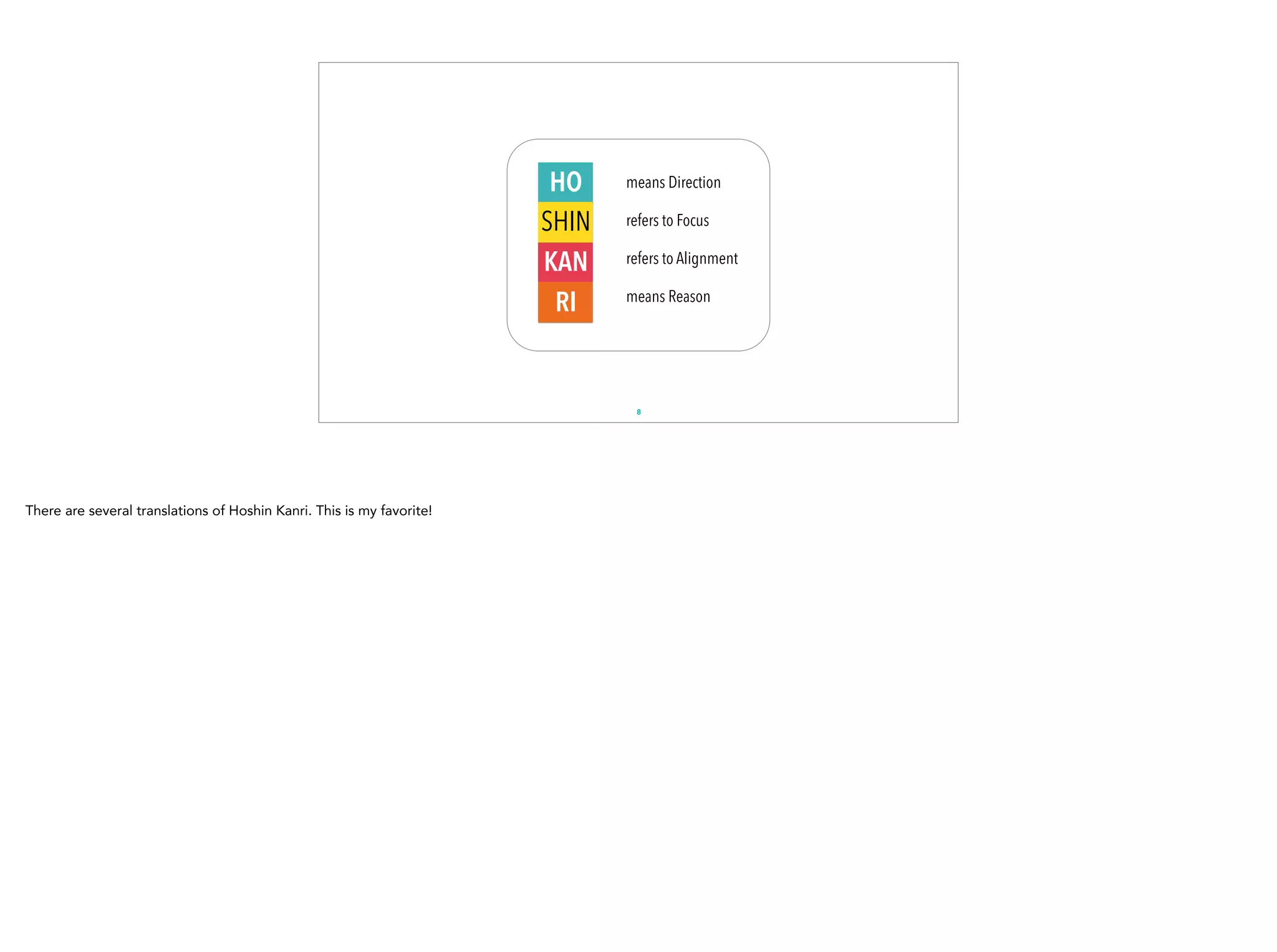

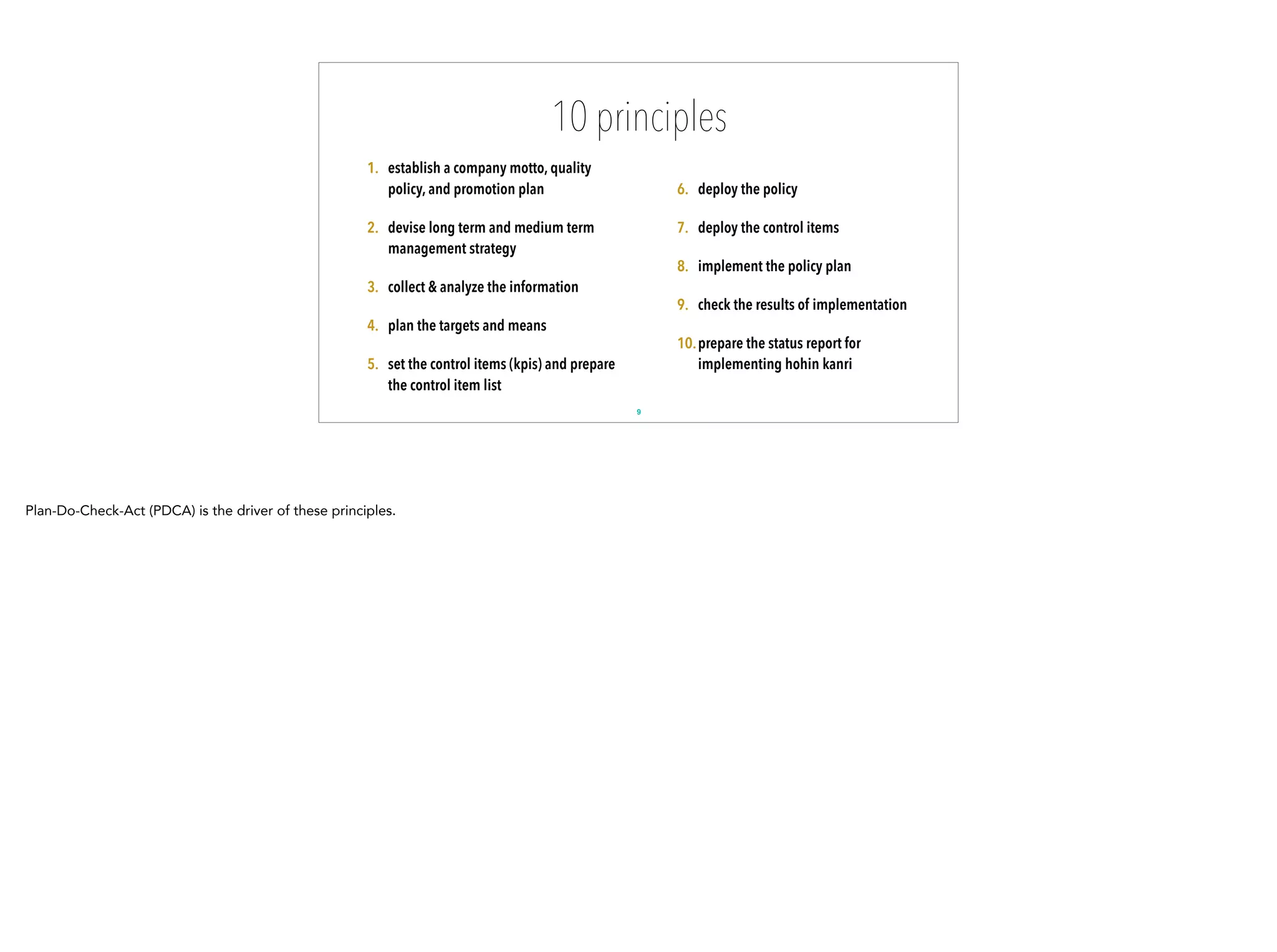

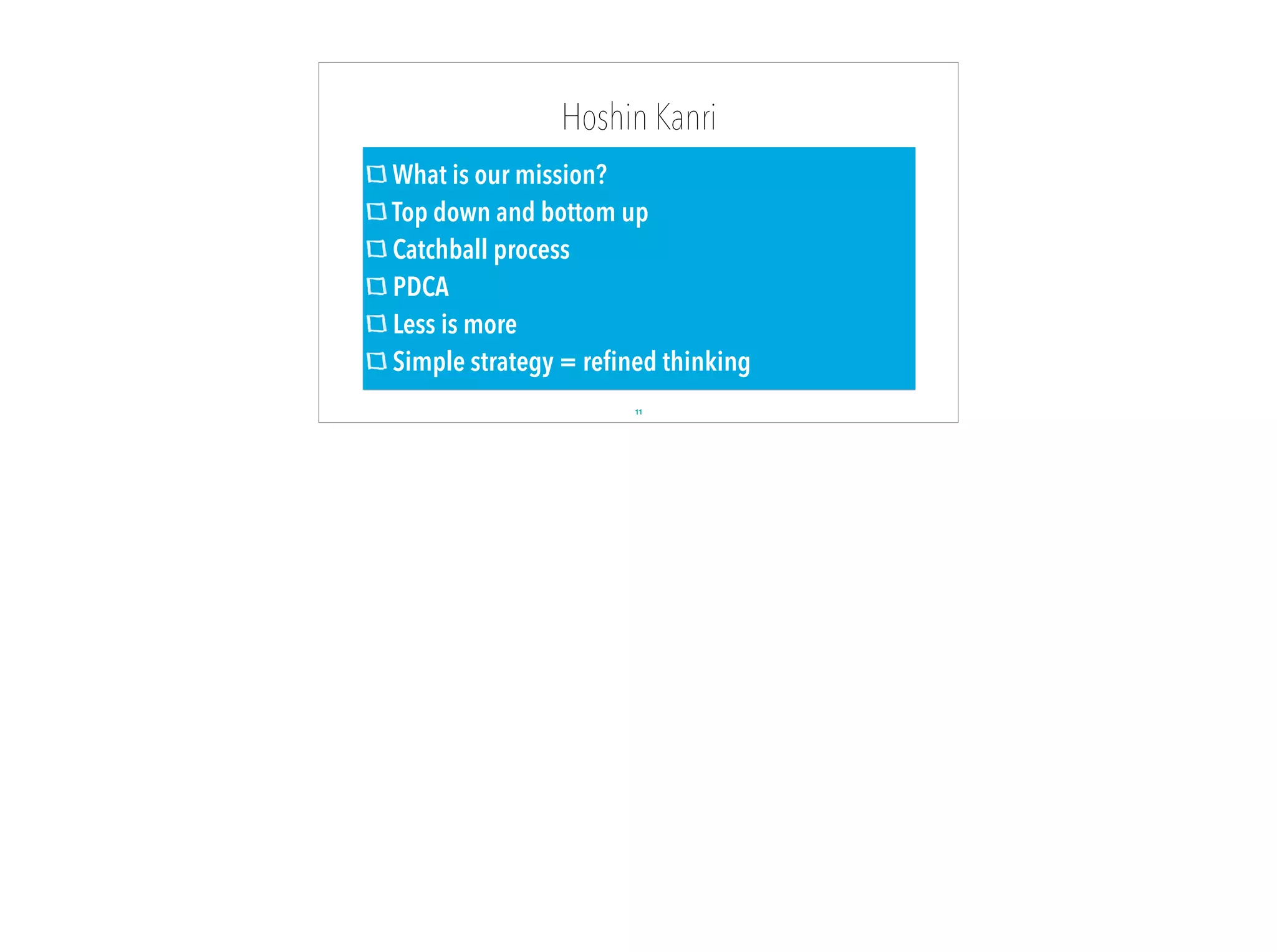

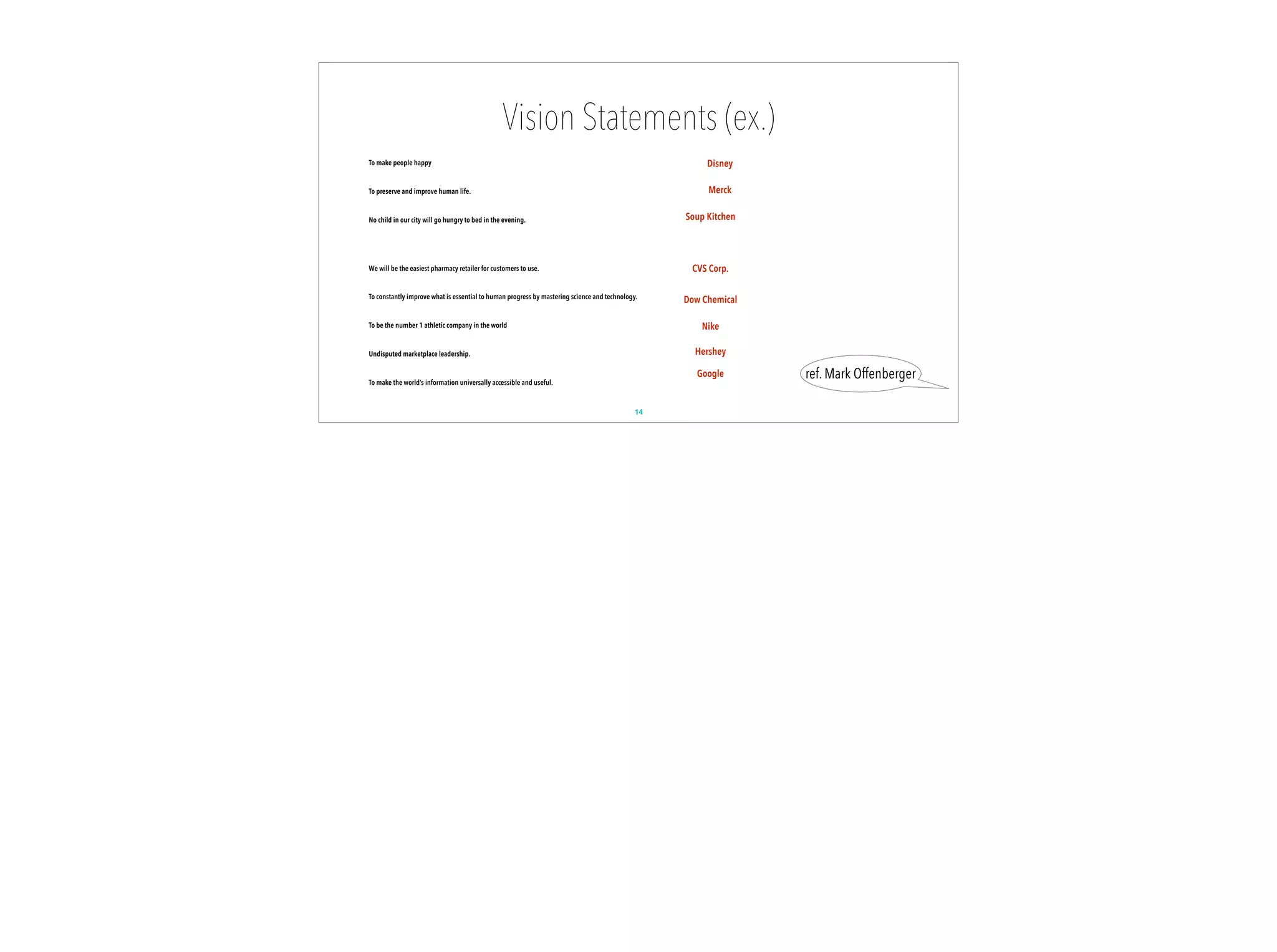

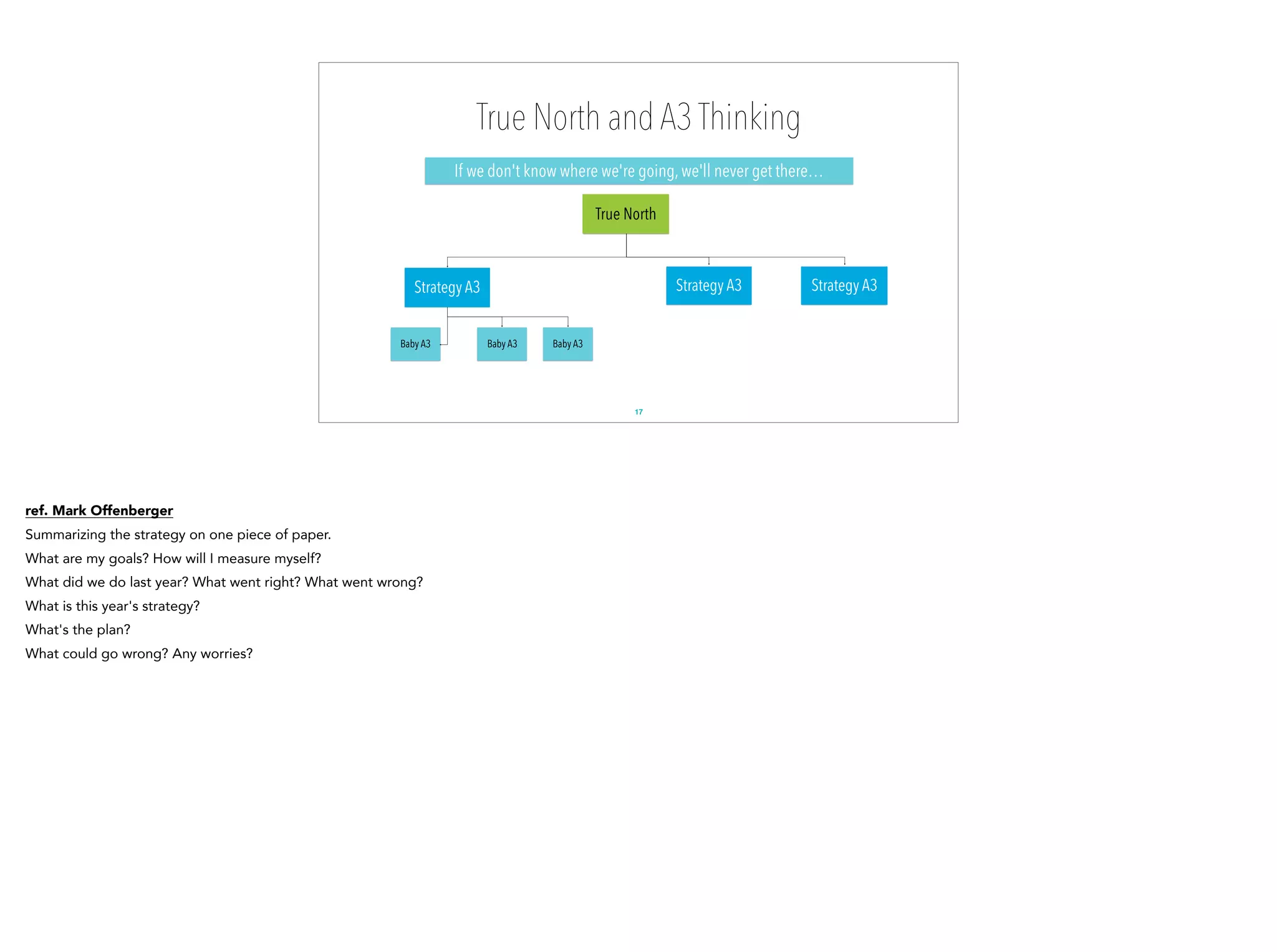

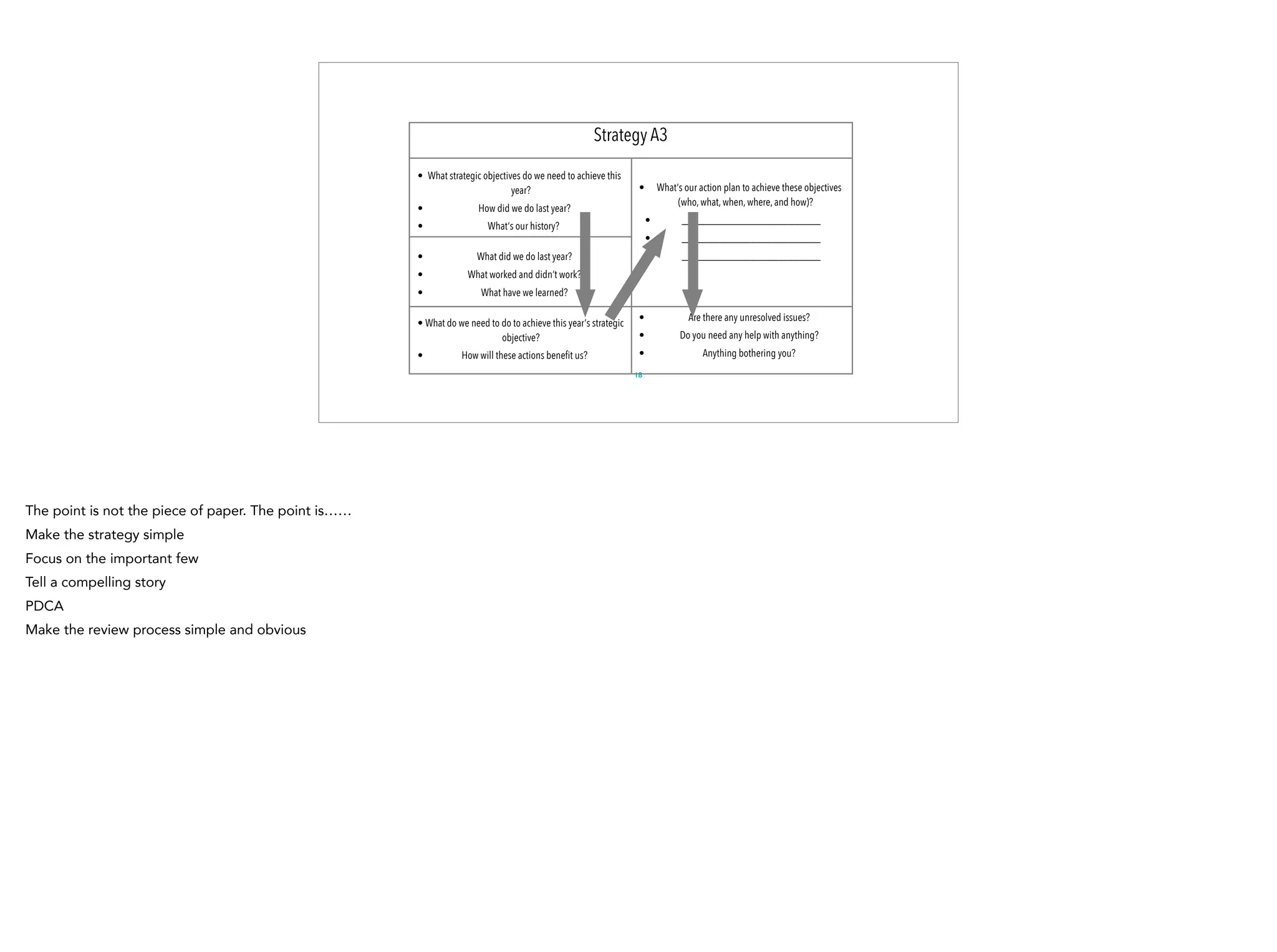

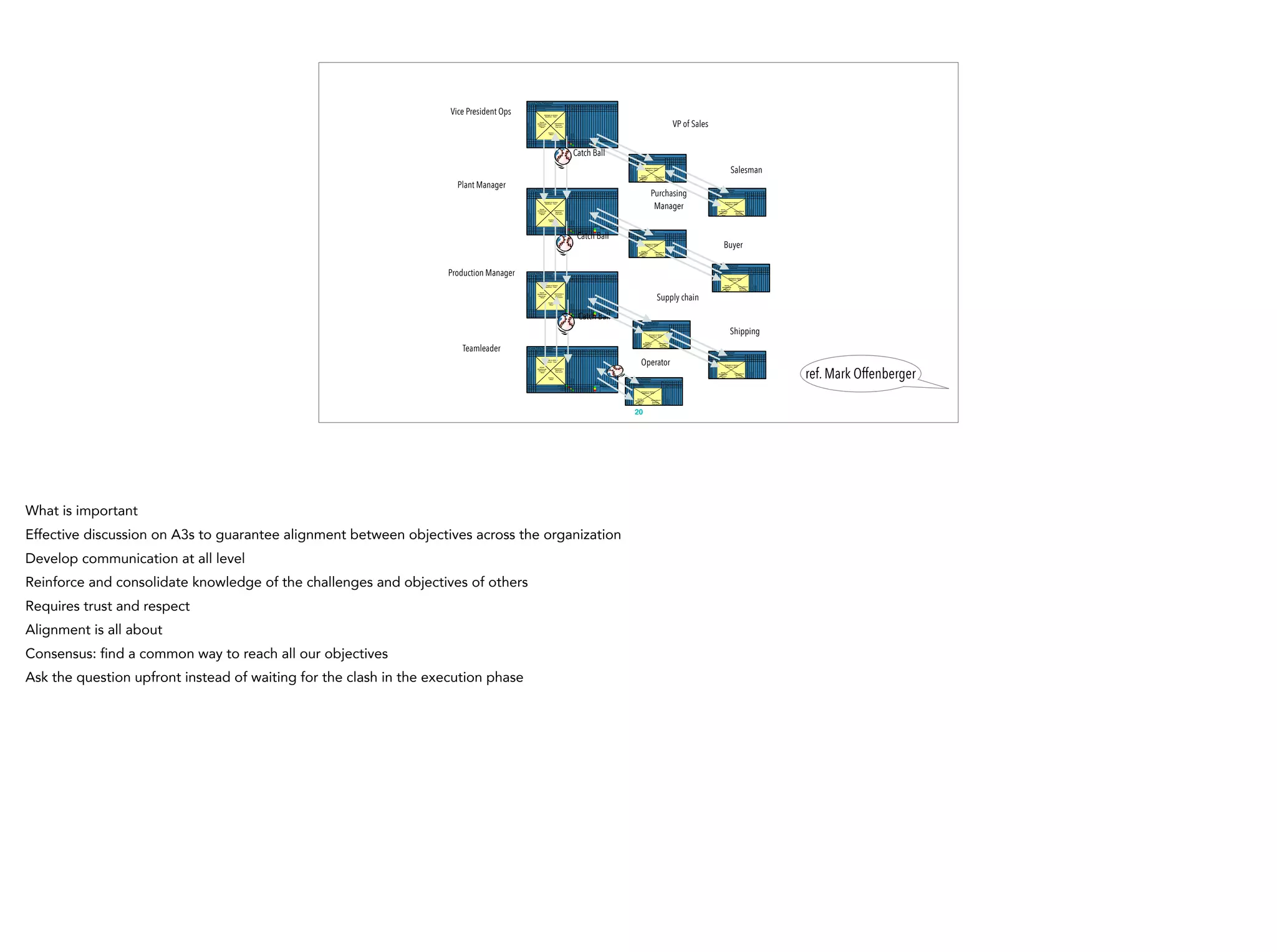

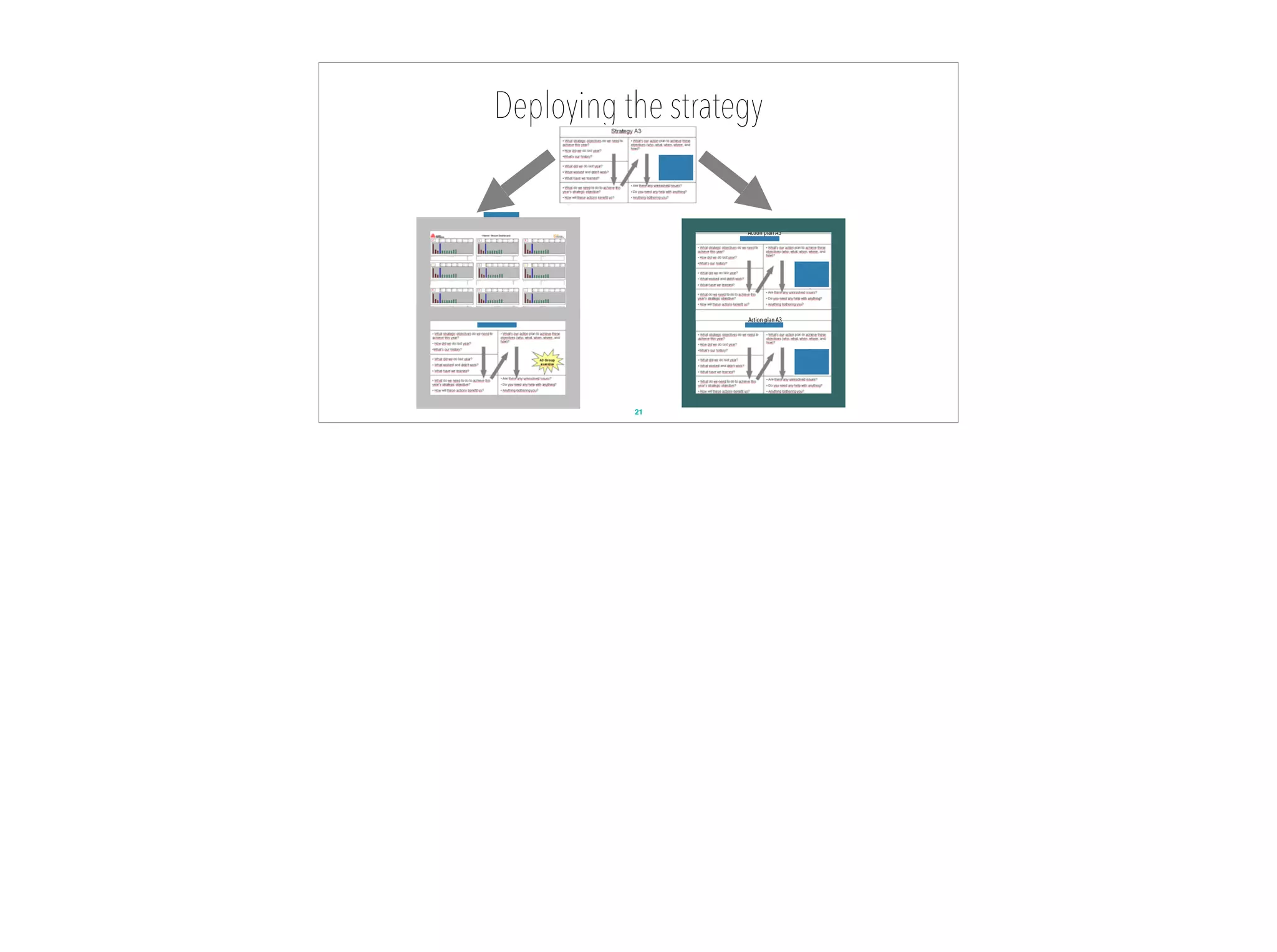

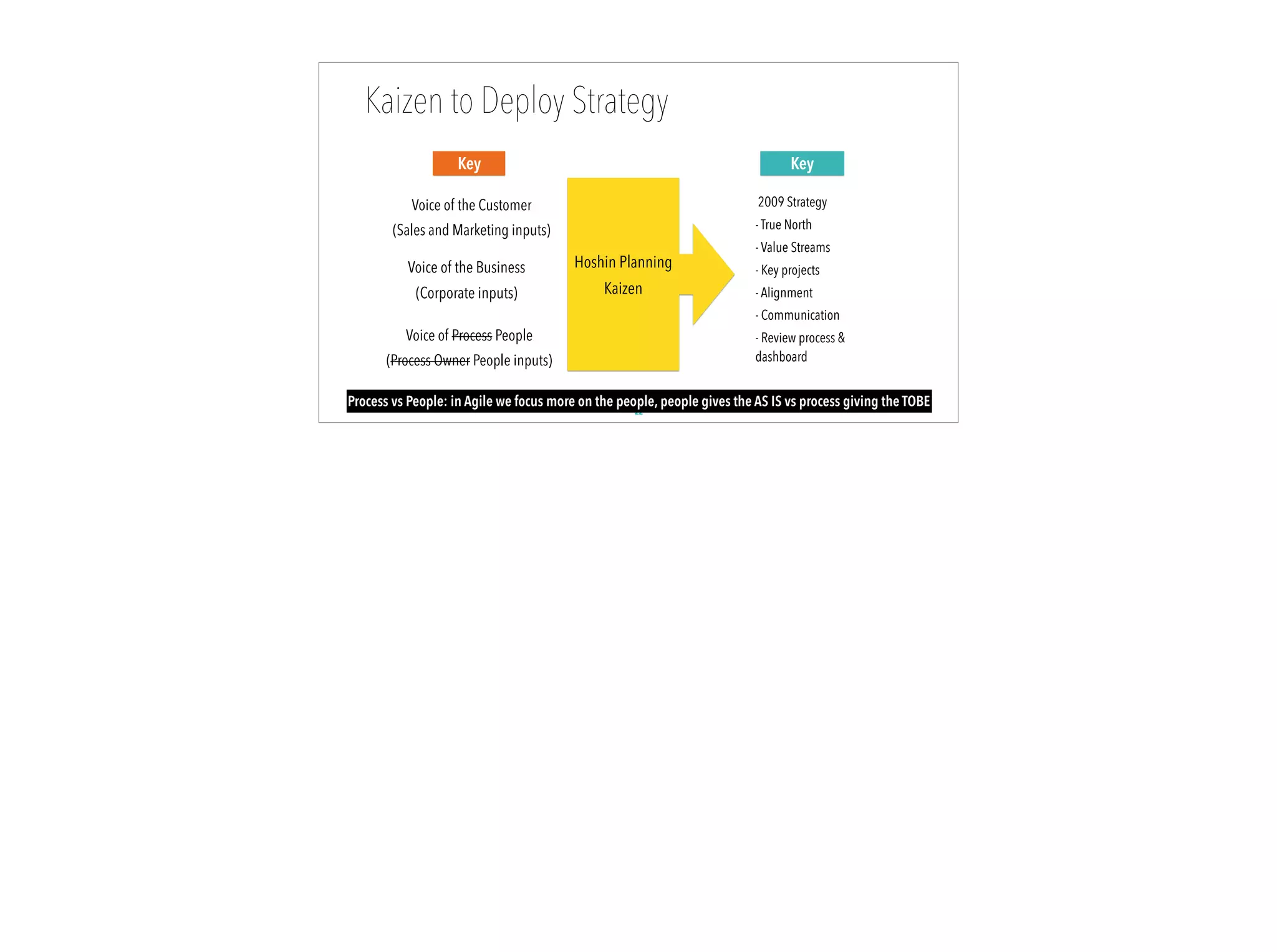

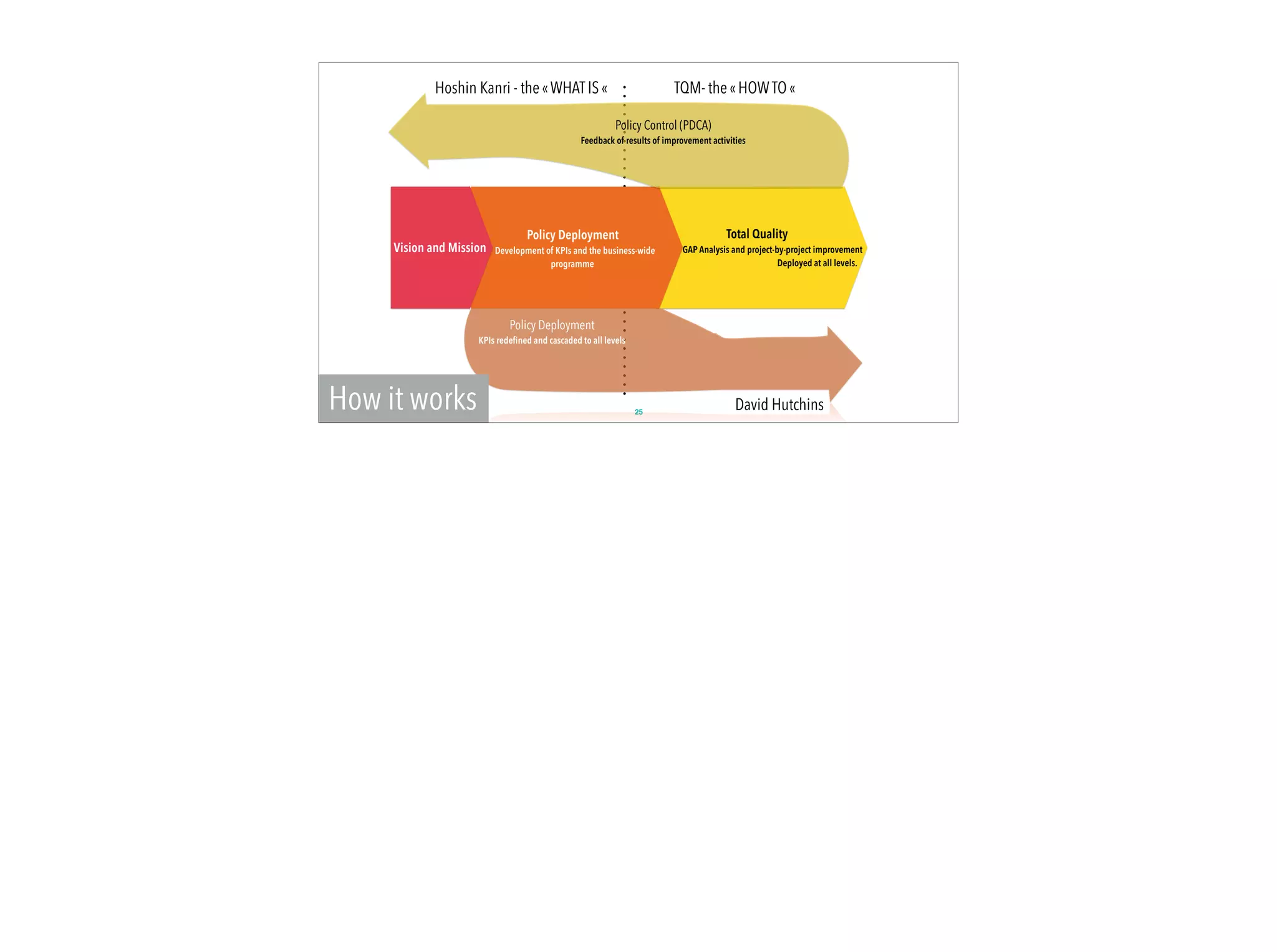

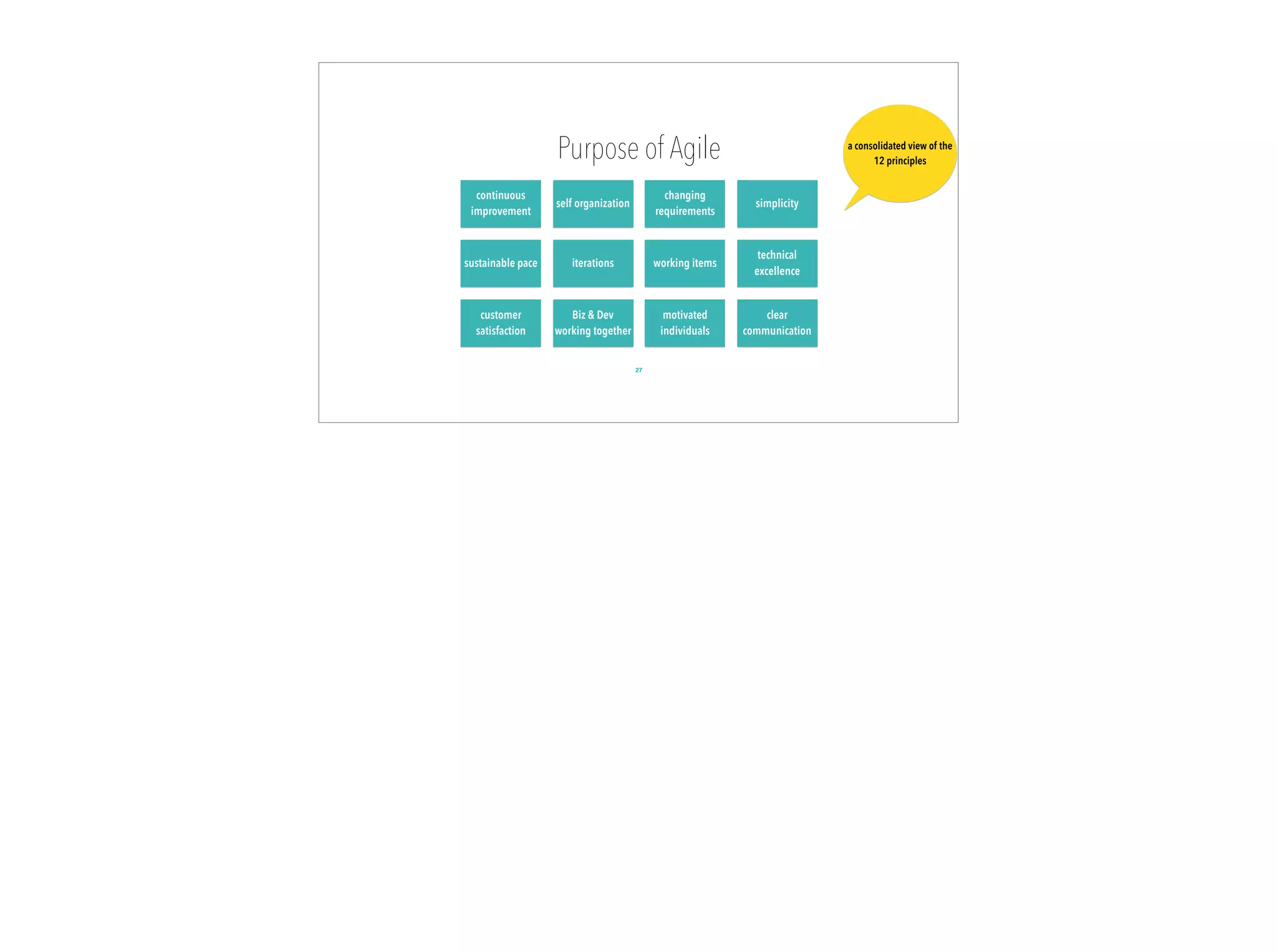

The document discusses the integration of Agile methodologies with Hoshin Kanri, emphasizing a strategic approach to continuous improvement through aligning organizational objectives with value streams. It highlights the importance of collective recognition of individual expertise in driving quality management and the role of PDCA in a fluid organizational structure. Additionally, it posits Hoshin Kanri as a foundational process for linking leadership actions with effective management processes within agile frameworks.