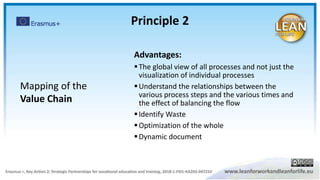

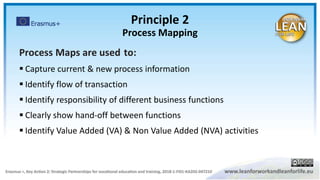

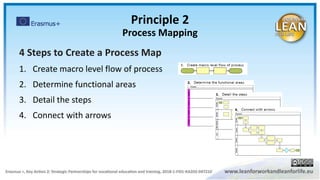

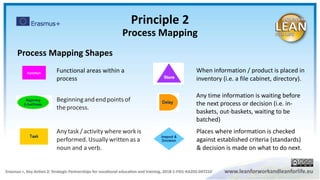

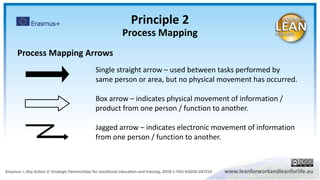

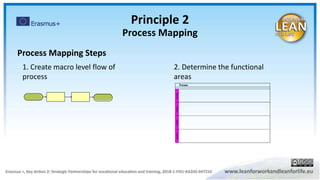

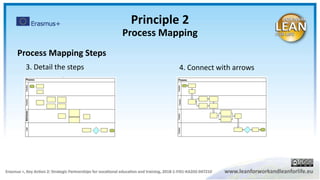

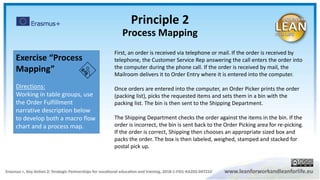

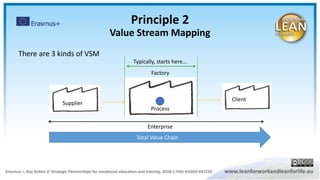

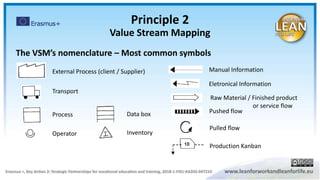

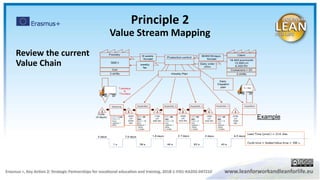

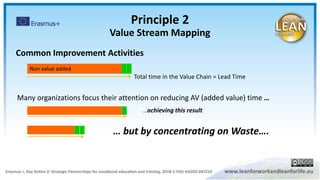

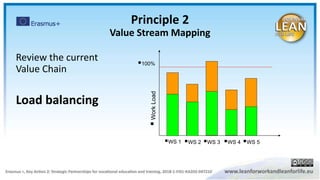

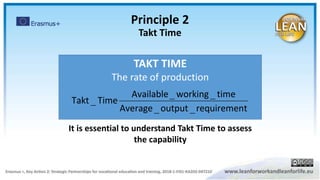

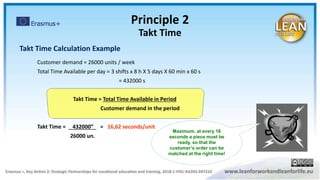

This document discusses lean principles for identifying a company's value chain. It defines key lean concepts like process mapping, value stream mapping, takt time, and cycle time. Process mapping involves documenting the steps in a process using standard shapes to identify functions, decisions, delays, and information flow. Value stream mapping takes a broader view of the entire process from supplier to customer. Takt time represents the rate of customer demand that operations must match. The goal of these lean tools is to identify waste and optimize process flow and productivity.