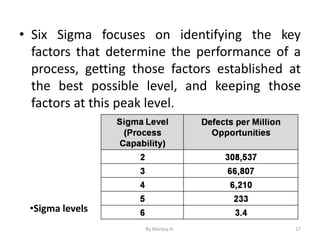

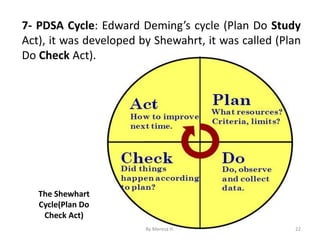

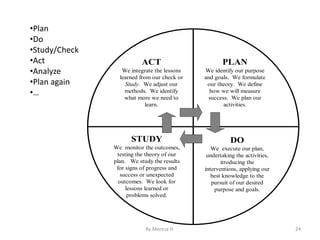

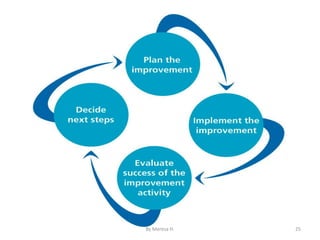

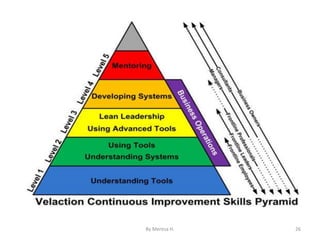

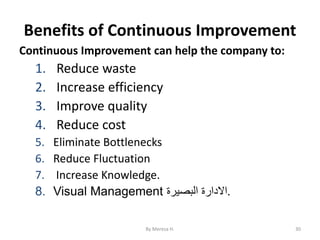

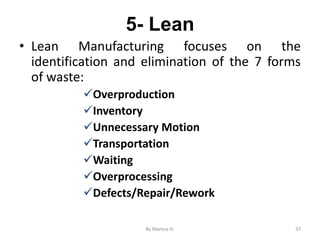

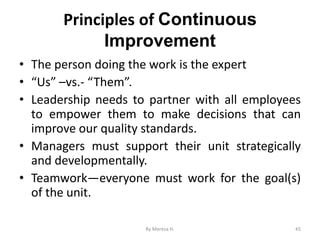

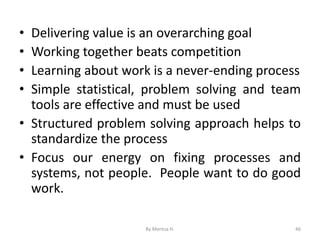

Continuous improvement (also called continual improvement) is a quality philosophy that seeks to improve processes on an ongoing basis. It involves measuring effectiveness, identifying opportunities for improvement, implementing small changes, and continually striving to meet more challenging goals. Key aspects of continuous improvement include establishing a quality culture, driving out fear, providing feedback mechanisms, responding quickly to customer needs, and standardizing procedures while continuously improving them. Common tools for continuous improvement include total quality management, kaizen, lean manufacturing, Six Sigma, and PDCA/PDSA cycles. Benefits include reduced waste, increased efficiency and quality, and lower costs.

![• What is Poka-yoke ( ポ カ ヨ ケ ?)?? تجنب

األخطاء [poka yoke] is a Japanese term that

means "mistake-proofing". A poka-yoke is any

mechanism in a lean manufacturing process

that helps an equipment operator avoid

(yokeru) mistakes (poka). Its purpose is to

eliminate product defects by preventing,

correcting, or drawing attention to human

errors as they occur لفت

االنتباه

الى

األخطاء

البشرية

14

By Meresa H.](https://image.slidesharecdn.com/managingcontinuousimprovementsyst-230808003357-d0b4e80a/85/Managing-Continuous-Improvement-Syst-pdf-14-320.jpg)