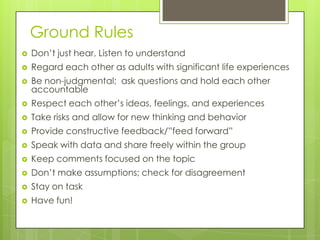

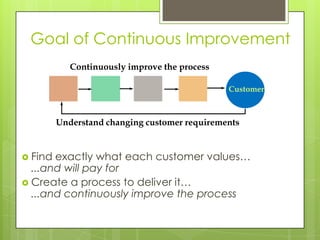

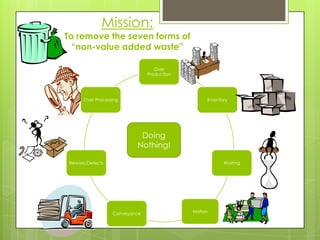

This document outlines the goals and principles of a continuous improvement event. It encourages participants to listen with an open mind, respect each other's ideas, and provide constructive feedback to help the team improve. The document explains that change is necessary to meet customers' evolving needs and remain successful. It defines value-added and non-value added processes, highlighting seven types of waste. The goal of continuous improvement is to continuously improve processes by understanding customer requirements and removing waste.