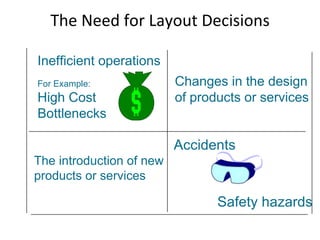

Layout involves arranging equipment and work areas to minimize costs while meeting production needs. A good layout considers space requirements, material flow, and costs of movement. It also aims to improve productivity, worker safety, and utilization of equipment and space. Layout decisions are important because they significantly impact costs and efficiency over the long-term.