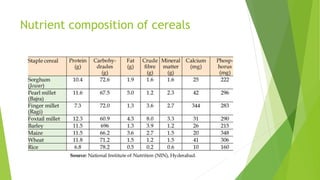

This document discusses traditional fermented cereal products. It begins by providing examples of common cereals like wheat, rice, maize, and others. It then discusses how cereals are important sources of nutrients. The document outlines the production process of traditional Ugandan fermented cereal products like bushera, amalwa, mageu, and umcombotsi. It describes how these products are made by mixing cereals with water or porridge and allowing natural yeasts and bacteria to ferment them. Precautions during fermentation include allowing sufficient time for fermentation and germination processes and ensuring quality of raw materials and uniform mixing.