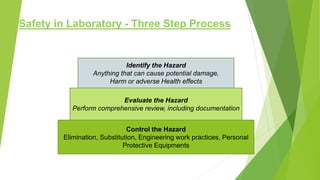

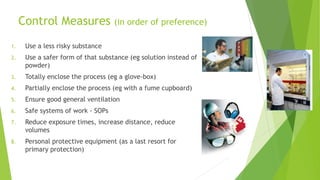

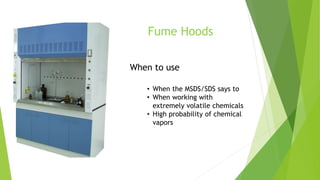

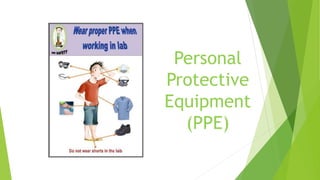

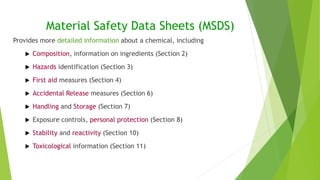

This document outlines general laboratory safety guidelines. It discusses why laboratory safety is important to protect workers, visitors, and the work. Laboratory hazards include fire, sharps, spills, pressure equipment, chemicals, and biological and radiation hazards. The key aspects of laboratory safety are to identify hazards, evaluate risks through assessments, and control risks following a hierarchy of controls. Control measures include elimination, substitution, engineering controls, administrative controls, and personal protective equipment. Proper hygiene, waste disposal, chemical storage, emergency procedures, and incident reporting are also covered.