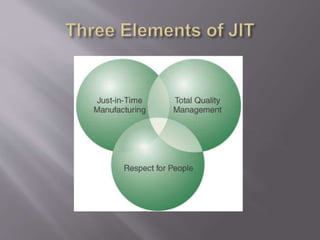

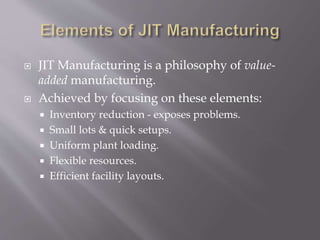

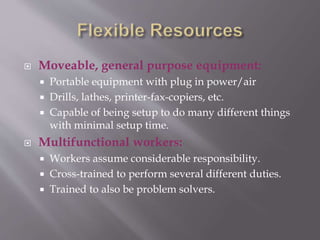

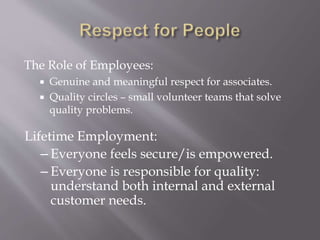

The document discusses Just-In-Time (JIT) systems. It provides background on JIT, noting that it aims to get the right quantity of goods to the right place at the right time with no waste. JIT originated at Toyota and gained prominence in the 1970s. The document outlines key elements of JIT like inventory reduction, small lots, uniform plant loading, and flexible resources. It also discusses how JIT focuses on continuous improvement, visibility of waste, and flexibility.