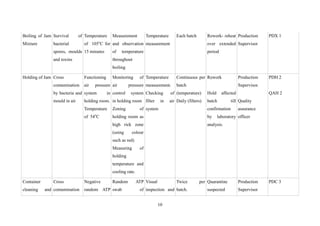

This document provides a Hazard Analysis and Critical Control Point (HACCP) plan for the production of apple jam. It begins with an introduction to jam and HACCP principles. A flow diagram of the apple jam production process is presented. Potential hazards at each step are identified, such as microbial contamination or chemical residues. Critical control points are established where limits can be set and monitored to prevent hazards, such as maintaining time/temperature standards during boiling. Record keeping, validation, and staff training procedures are discussed to ensure proper implementation and maintenance of the HACCP plan. The document aims to apply HACCP principles to identify, control, and document food safety hazards for the production of a shelf-stable apple jam product.

![16

References

1. Ali, I. 2004. Food Quality Assurance: Principles and Practices. CRC Press, UK.

2. Beatie, B. and Wade, N. 2001. Storage, Ripening and Handling of Fruits. In: Fruit

Processing: Nutrition, Products and Quality Management, 2ed. Eds. D. Arthely and P.R.

Ashurst. Aspen Publishers, Maryland, USA.

3. Broomfield, R.W. 2001. The Manufacture of Preserves, Flavourings and Dried Fruits. In:

Fruit Processing: Nutrition, Products and Quality Management, 2ed. Eds. D. Arthely and

P.R. Ashurst. Aspen Publishers, Maryland, USA.

4. Burrows, G. 2001. Quality Management System and Hazard Analysis Critical Control Point.

In: Fruit Processing: Nutrition, Products and Quality Management, 2ed. Eds. D. Arthely and

P.R. Ashurst. Aspen Publishers, Maryland, USA.

5. Codex, 1997. Recommended International Code of Practice, General Principles of Food

Hygiene. Codex Alimentarious Commission, Joint FAO/WHO Food Standards Program.

Rome.

6. Deshpande, S. 2002. Handbook of Food Toxicology. Marcel Dekker Incorporated, UK.

7. EC, 2004. Regulation (EC) No. 852/2004 of the European Parliament and the Council.

Official Journal of the European Union, Brussels.

8. EC, 2001. Council Directive 2001/113/EC. Official Journal of the European Communities,

Brussels.

9. EC, 2007. Council Regulation (EC) No. 834/2007. Official Journal of the European Union,

Brussels.

10. FDA/CFSAN, 2003. Food borne Pathogenic Microorganisms and Natural Toxins Handbook:

The 'Bad Bug Book'. Centre for Food Safety and Applied Nutrition / Food and Drug

Administration, Madison. Available online [4.01.2008] www.cfsan.fda.gov

11. ICMSF, 2006. 'Microorganisms in Food 5, Characteristics of Microbial Pathogens'.

International Commission on Microbiological Specifications for Food. Blackie Academic

and Professional, London, UK.

12. Lindroth, S. And Niskanen, O. 1978. Comparison of Potential Patulin Hazard in Home-

made and Commercial Apple Products. Journal of Science.

13. Seiler, E. 1977. Jam and Confectioneries. Baking Industries Journal. January Issue, Page 4.

14. Vogel, B.F. 2007. Methods for Control of Cleaning and Disinfection. Slides from Lectures in

Hygiene and Sanitation (11.10.2007), course no. 270054. The Faculty of Life Sciences,](https://image.slidesharecdn.com/krishnakumarthulasimani-haccpplanforapplejam-190430053535/85/Jam-HACCP-Plan-17-320.jpg)