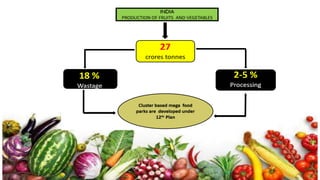

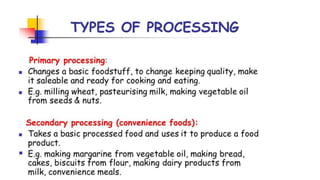

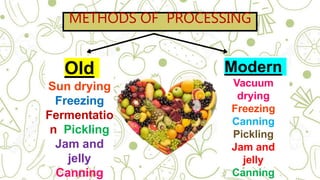

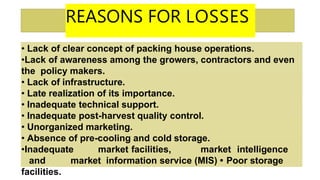

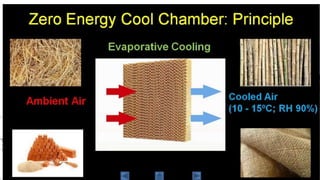

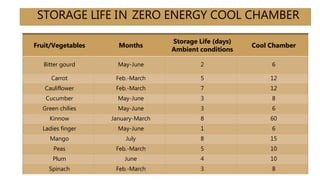

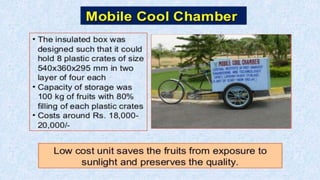

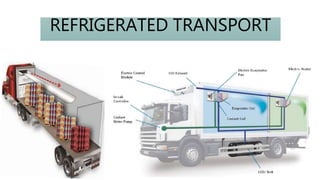

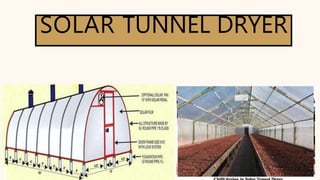

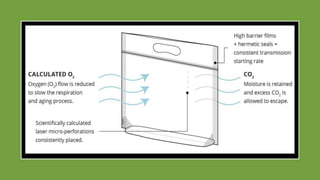

The document discusses food processing and post-harvest technology, highlighting techniques that transform raw ingredients into food and enhance its shelf life. It addresses post-harvest management, emphasizing the importance of proper handling and storage to reduce losses, which can be as high as 40% in fruits and vegetables. Various factors affecting post-harvest losses and methods for improvement, such as the use of cool chambers and proper packaging, are also outlined.