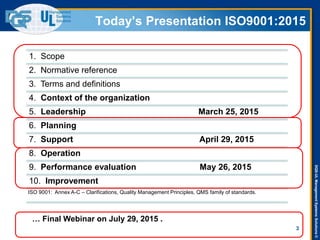

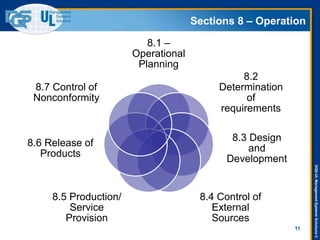

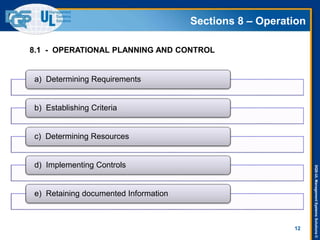

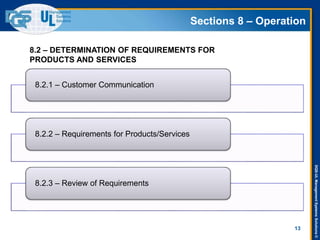

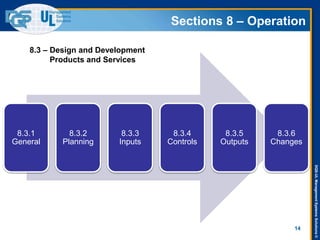

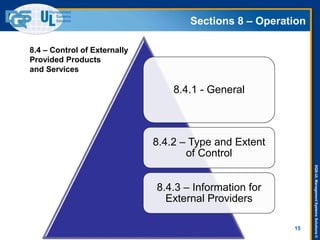

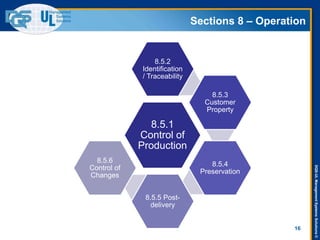

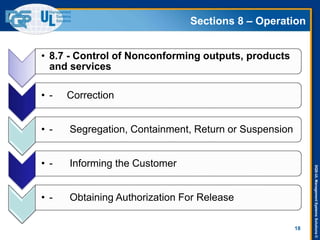

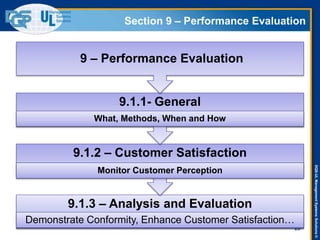

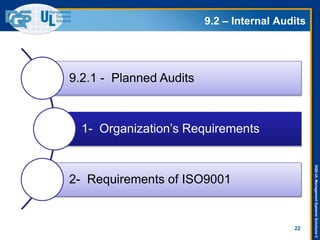

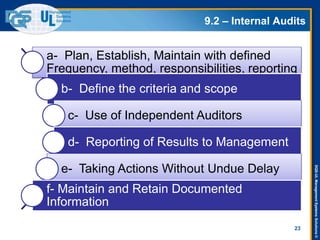

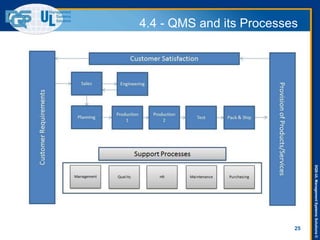

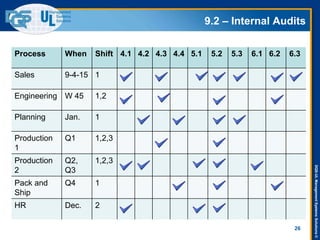

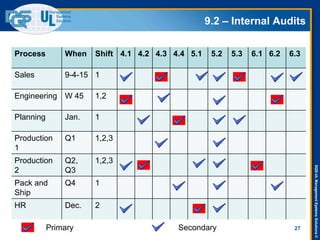

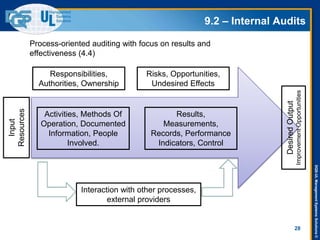

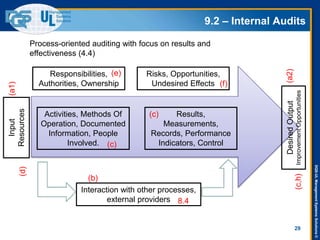

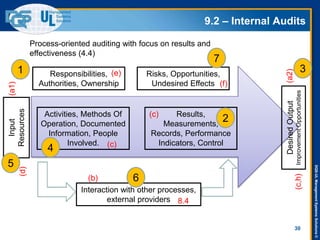

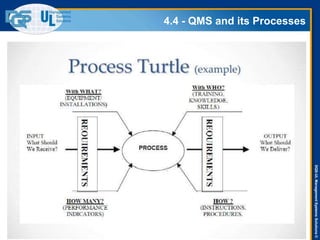

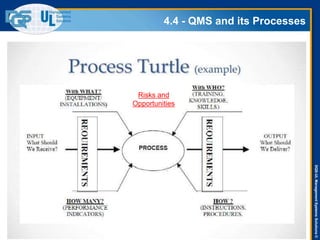

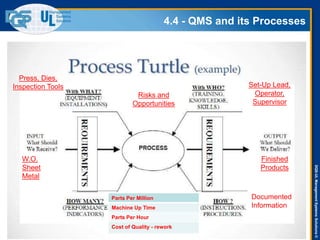

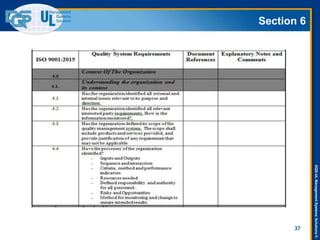

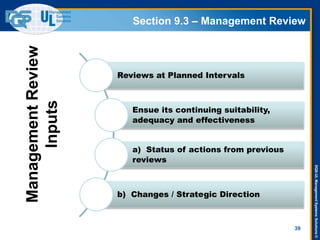

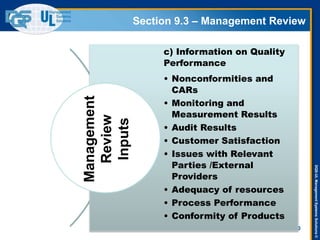

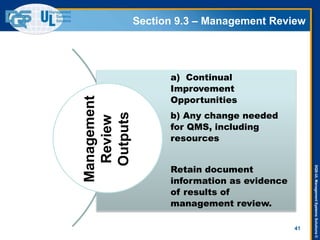

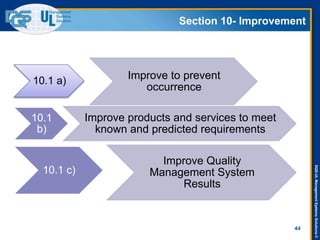

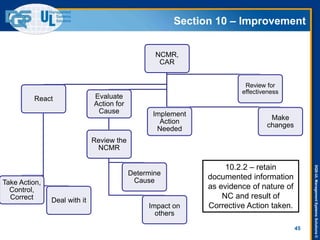

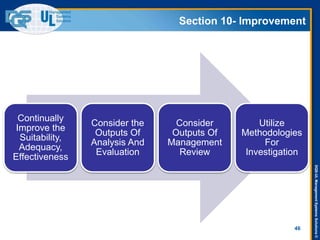

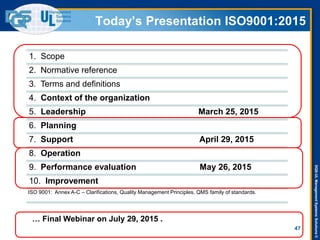

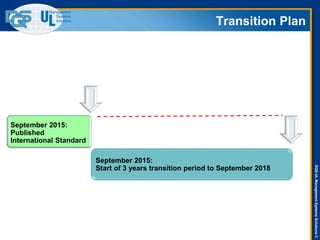

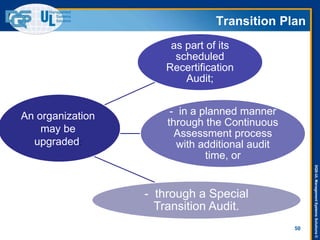

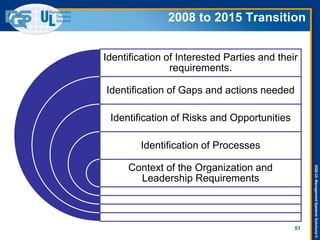

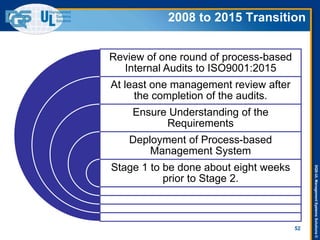

The document provides an overview of the ISO 9001:2015 standards, including its scope, normative references, terms and definitions, and sections on leadership, operation, performance evaluation, and improvement. It discusses the transition plan from ISO 9001:2008 to ISO 9001:2015, detailing the necessary audits, management reviews, and documentation required for compliance. The document also addresses common questions concerning audits and documentation accessibility related to the ISO standards.