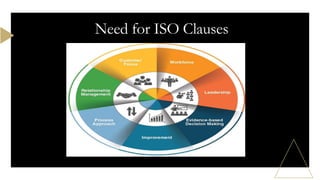

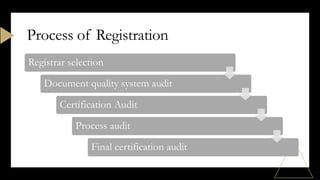

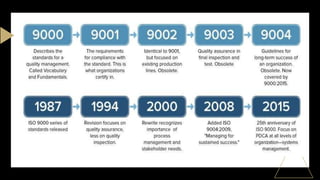

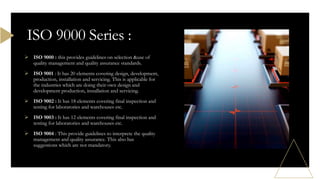

The document outlines the principles of operations management and the ISO 9000:2000 standards that provide guidelines for efficient quality management systems. It emphasizes the importance of customer satisfaction, process management, and continual improvement to enhance organizational efficiency and competitiveness. Various ISO standards are listed, including ISO 9001, 9002, 9003, and others that cater to different aspects of quality and management.