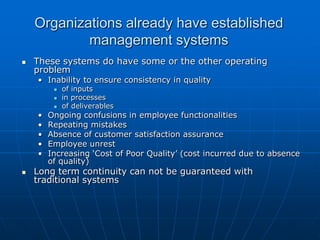

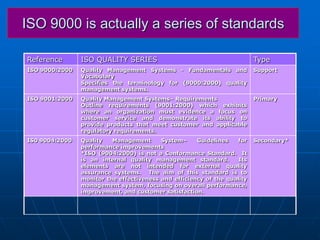

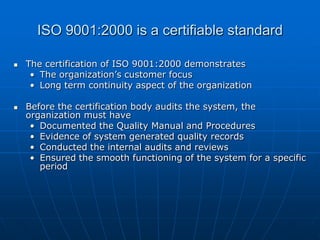

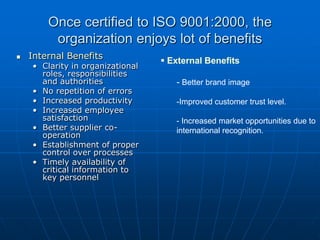

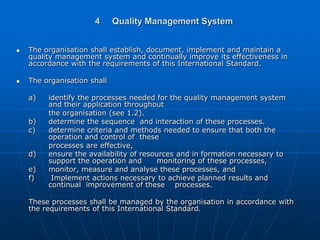

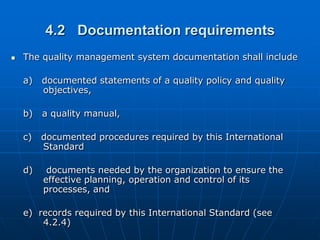

This document discusses ISO 9001:2008 quality management system standards. It provides an overview of the benefits of ISO 9001 certification for growing organizations, including improved quality, productivity, financial performance and long-term sustainability. It also summarizes the key requirements of the ISO 9001:2008 standard, including establishing documented procedures, conducting management reviews, ensuring customer focus, setting quality policies and objectives, and defining responsibilities.