The document proposes an Individual Quick Freezing (IQF) plant for freezing selected Bangladeshi fish. Key details include:

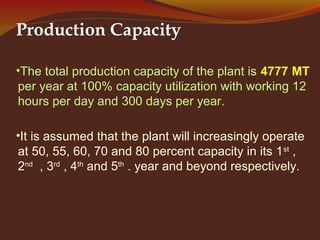

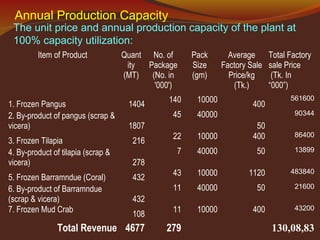

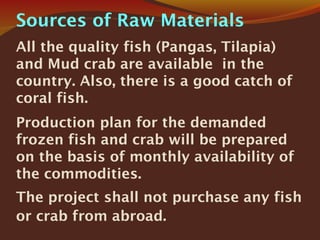

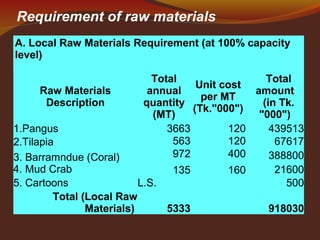

- The plant would have a production capacity of 4,777 metric tons per year and freeze fish like pangus, tilapia, barramundi, and mud crab.

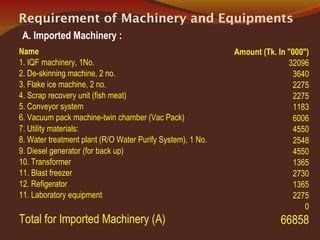

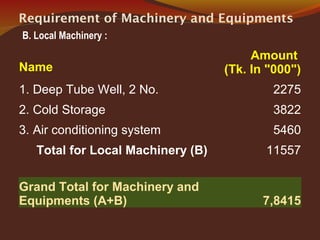

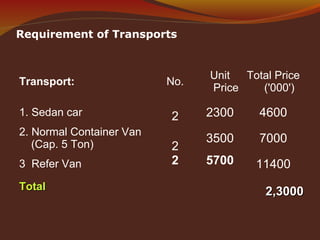

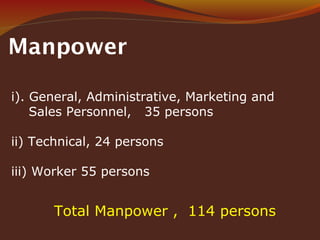

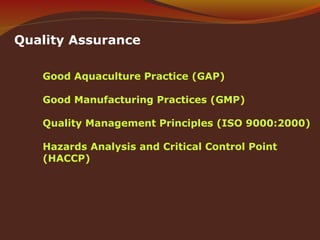

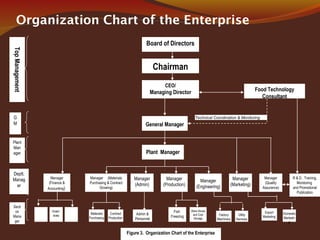

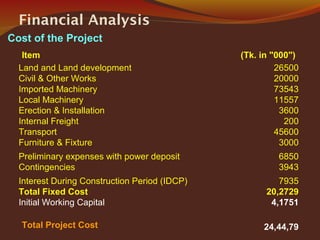

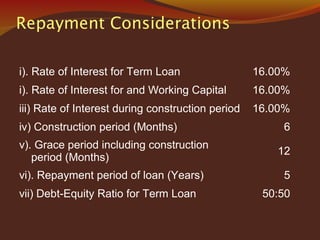

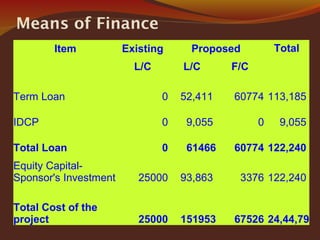

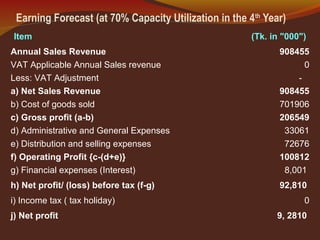

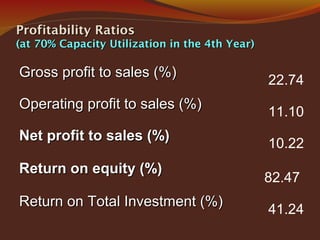

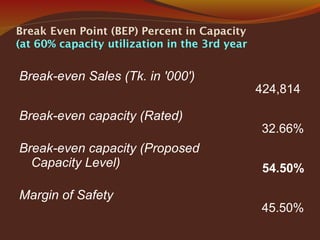

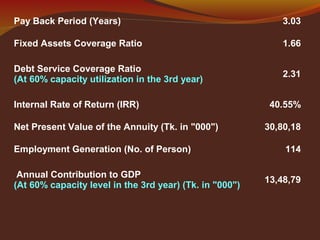

- Raw materials, machinery, manpower needs, and financial projections are presented, showing the plant could be profitable with an IRR of 40.55% and payback period of 3.03 years.

- A SWOT analysis finds strengths in high quality offerings and opportunities in raw material availability and incentives, but weaknesses in country image and threats from established brands. The conclusion recommends the project as frozen