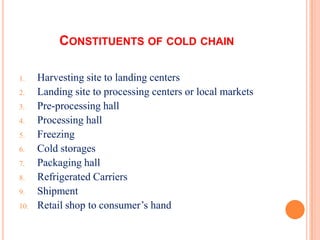

Cold chain refers to temperature controlled supply chain used to preserve quality and shelf life of perishable products from harvesting to consumer. It involves harvesting, transportation, processing, storage and distribution at specified temperatures. Proper cold chain is needed to restrict microbiological growth and maintain quality of fish products. It consists of harvesting, transportation to landing centers and processing plants, pre-processing, processing, freezing, storage, packaging, transportation and retail. Strict temperature control and hygiene protocols must be followed at each stage as per FAO guidelines, however cold chain implementation in India still needs improvement.