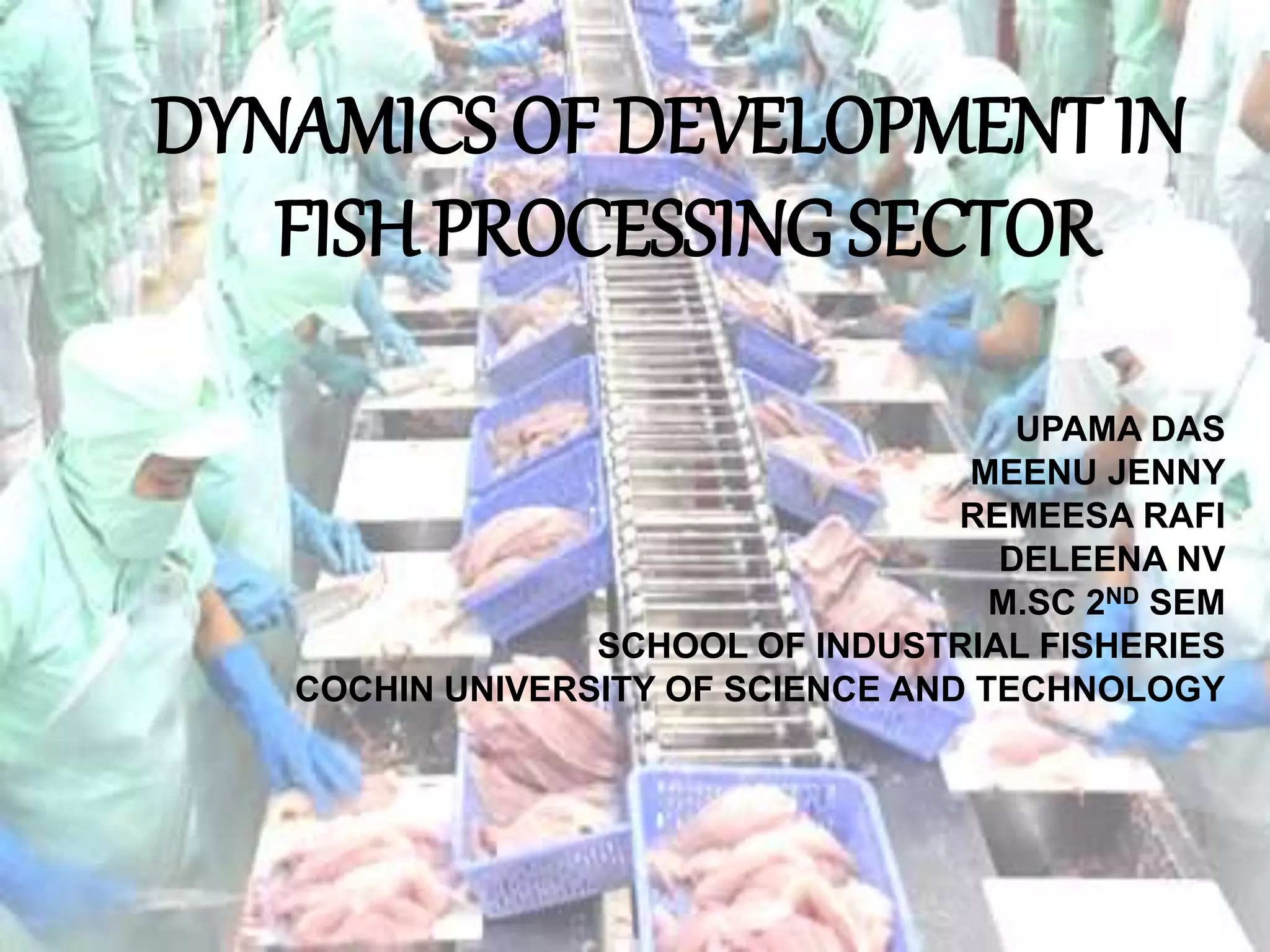

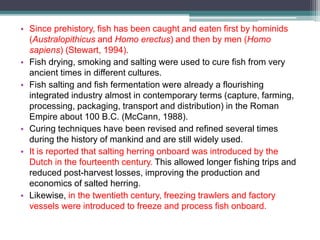

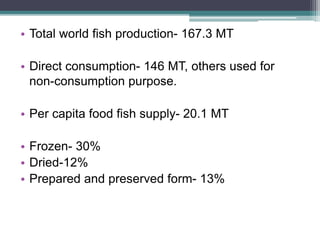

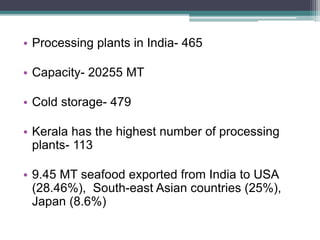

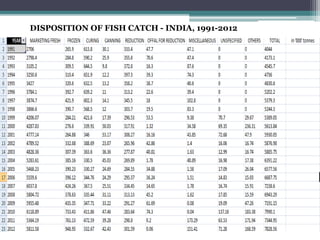

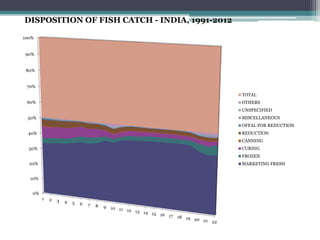

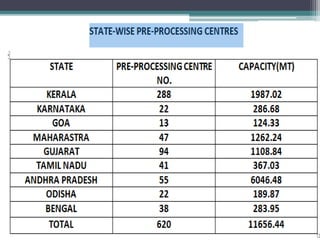

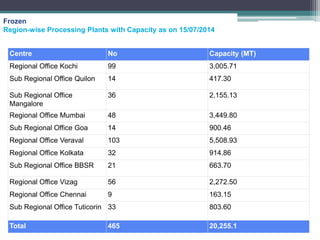

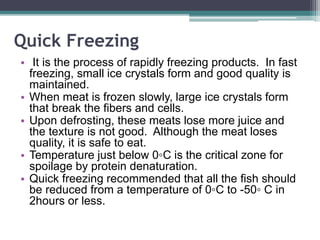

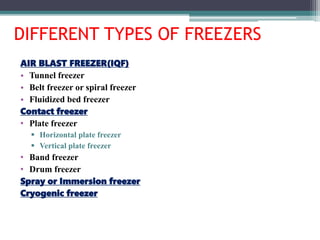

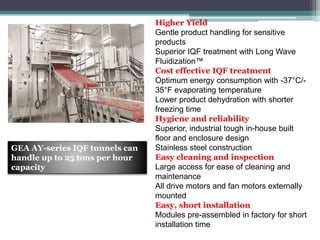

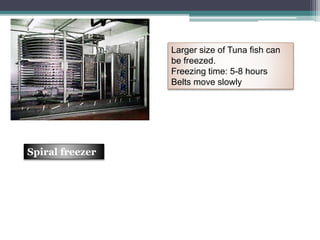

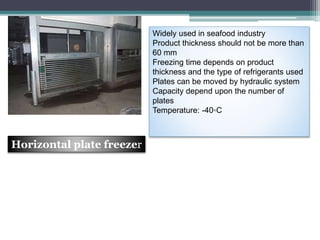

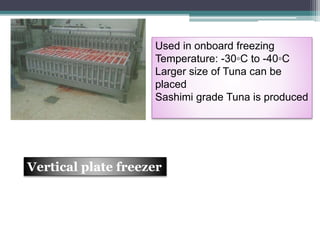

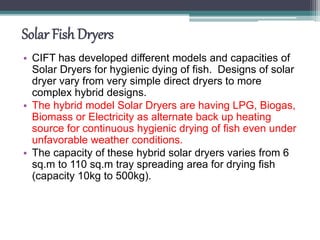

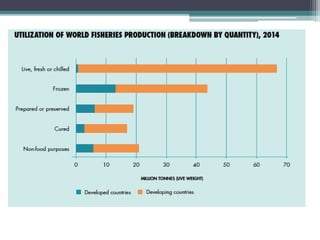

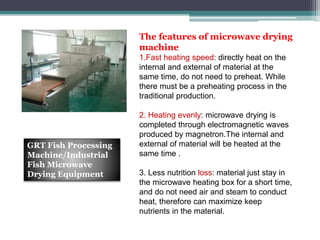

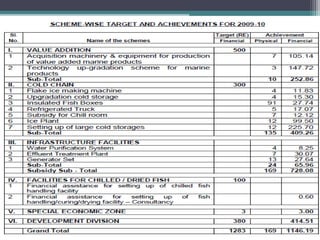

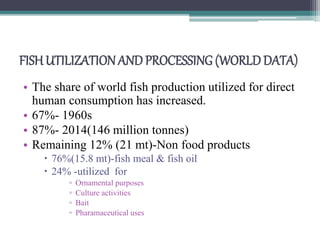

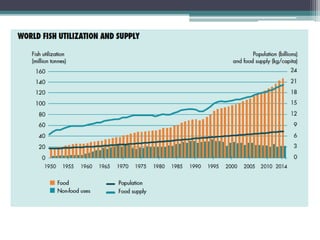

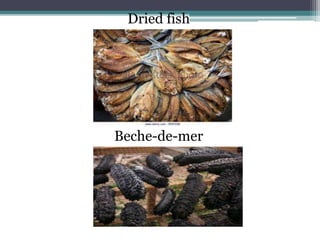

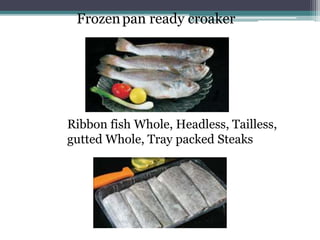

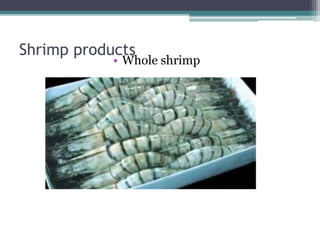

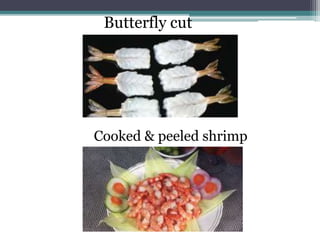

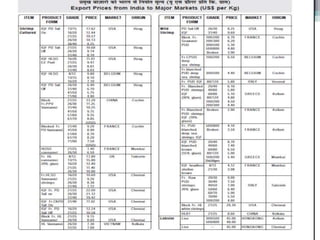

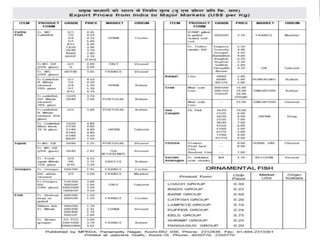

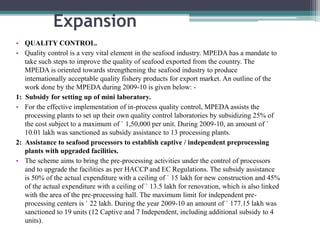

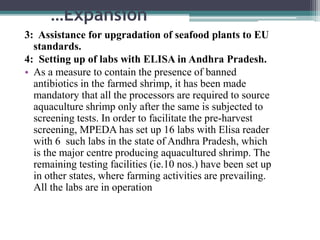

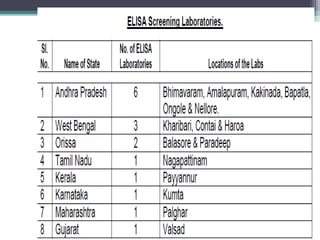

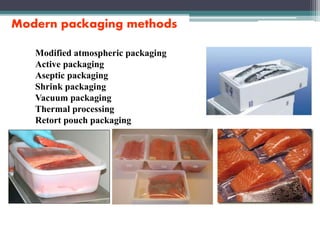

This document discusses technological developments in the fish processing sector. It begins by defining fish processing and describing some common processing techniques like drying, salting, smoking, chilling and freezing. It then discusses developments in product development, packaging modernization, quality control and processing infrastructure in India. Specific technologies like quick freezing, IQF freezing, cryogenic freezing and types of freezers are explained. The document highlights India's growth as a major fish exporter and continued opportunities for investment and improvement in the fish processing sector through adoption of new technologies.