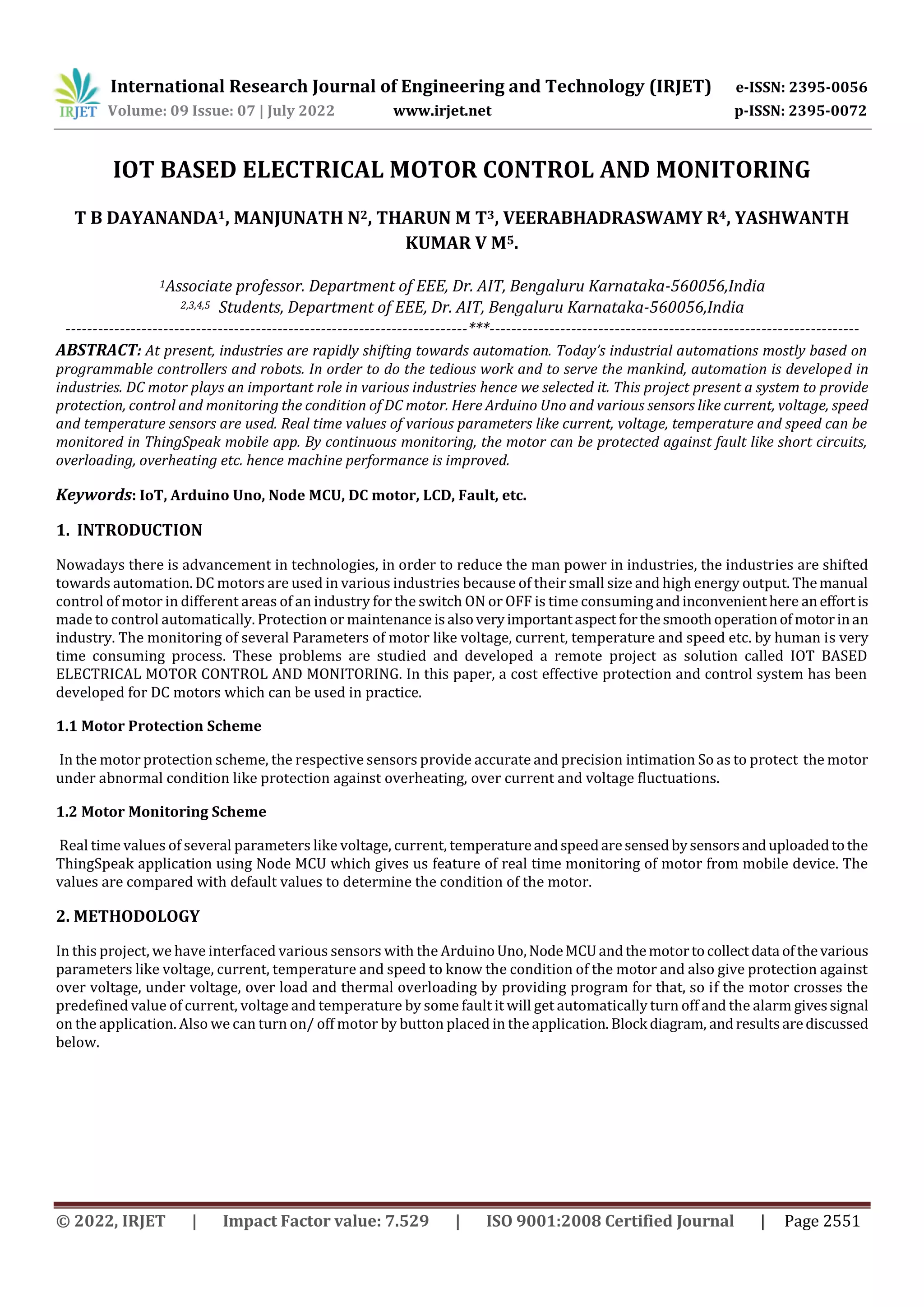

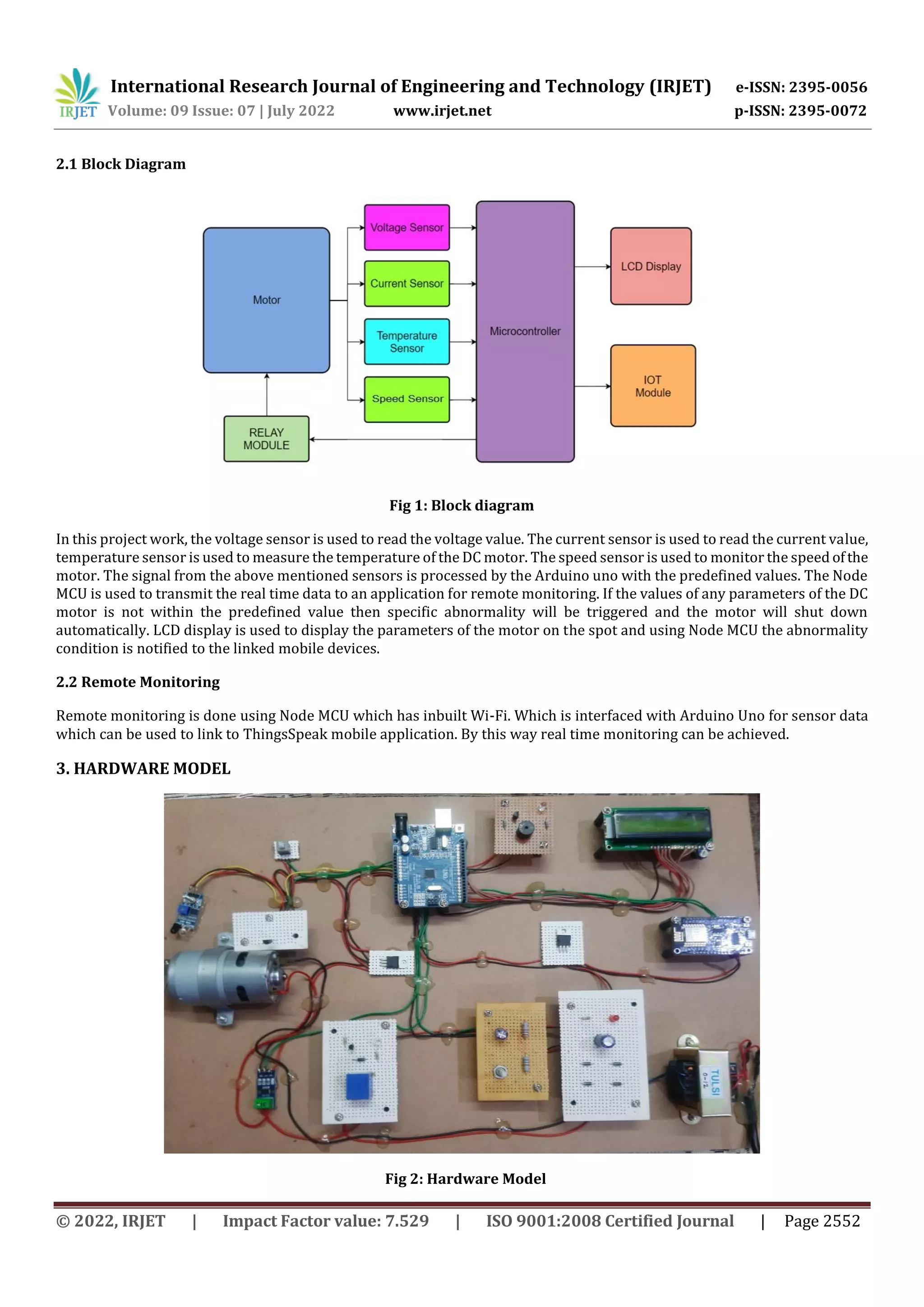

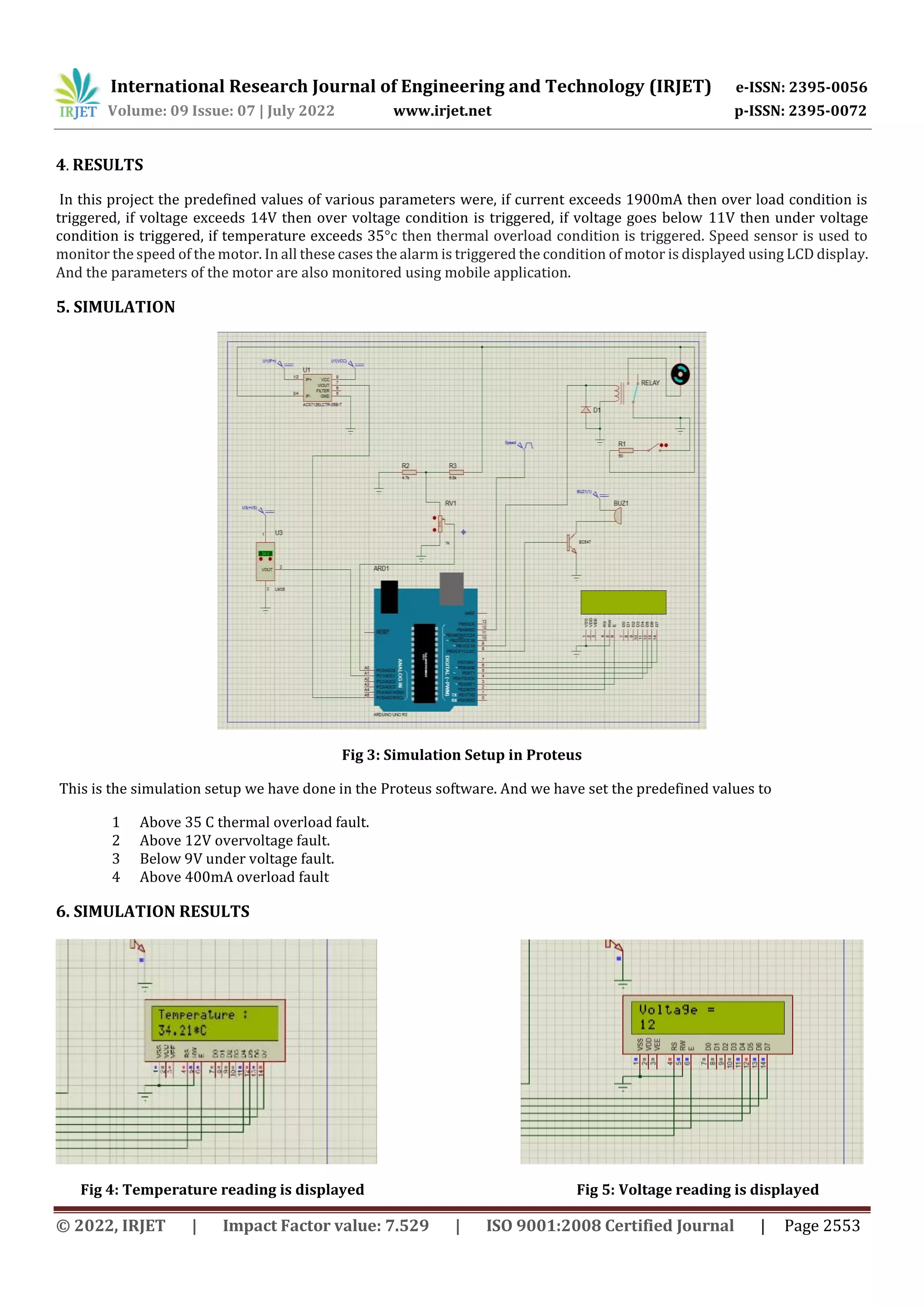

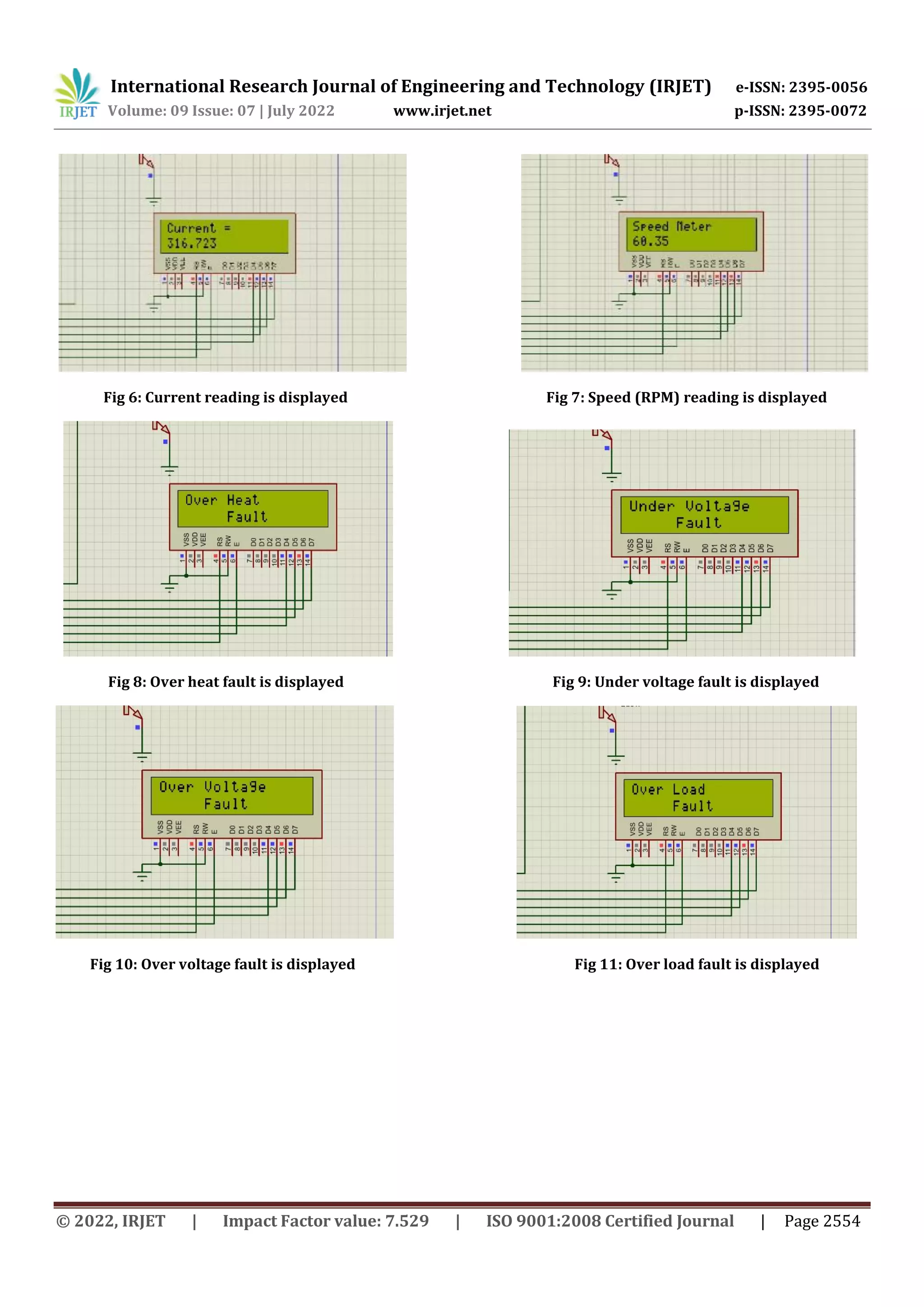

This document presents a system for monitoring and protecting a DC motor using IoT. Sensors are used to measure the voltage, current, temperature, and speed of the motor. An Arduino Uno collects data from the sensors and compares the values to predefined thresholds. If a threshold is exceeded, a fault is triggered and the motor is shut off. A Node MCU transmits the sensor data to a mobile app for remote monitoring. The system was simulated in Proteus and successfully detected faults like overheating, overvoltage, undervoltage, and overloading. This allows for protection of the motor from damage and improved performance through continuous condition monitoring via a smartphone.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 07 | July 2022 www.irjet.net p-ISSN: 2395-0072

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page 2556

8. CONCLUSION

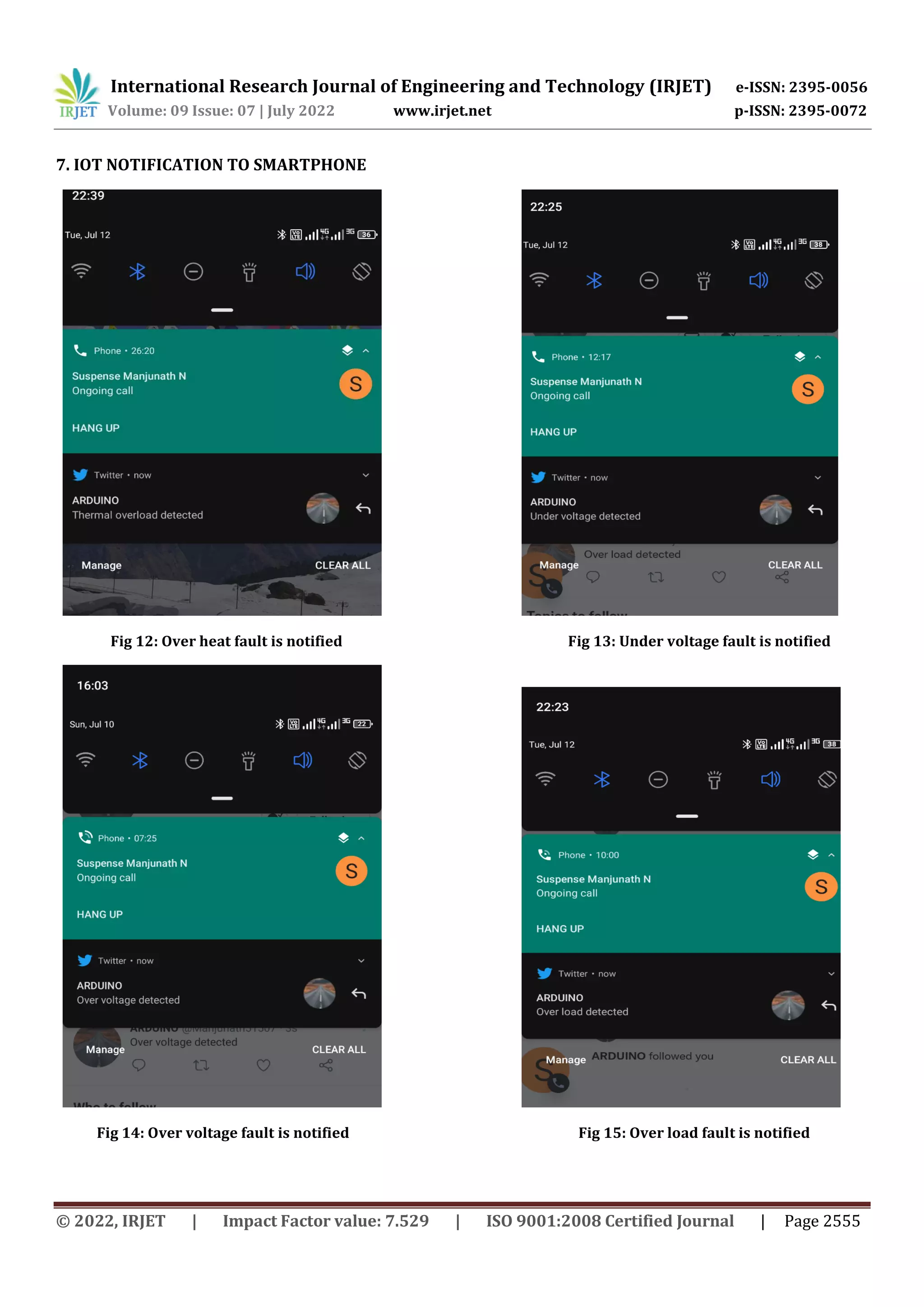

In this project, a system introduced that can protect, control andmonitora DCmotorthroughmobileapplicationusingArduino

Uno and Node MCU. Various parameters like current, voltage temperature and speed and their real-time values can observed

on the screen. Protection against the overload, overvoltage, under voltage and overheating is achieved. Also we have

successfully completed simulation part of this project.

9. REFERENCES

[1] S.U.PRABHA, S.PAVITHRA, International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395- 0056

Volume: 07 Issue: 03, April-2020.

[2] JYOTHI B GADADE, BE. Student Dept. of Electrical Eng., S. B Patil college of engineering, Maharashtra, India, (IRJET-

V5I5666) eISSN:2395-0056, May-2018.

[3] PREETHI. R, DHIVYA. N, Knowledge institute of technology, Kakapalayam, Salem, (IRJET- V2I6189) e-ISSN:2395-0056,

September-2015.](https://image.slidesharecdn.com/irjet-v9i7528-221027064315-bc9ac5e1/75/IOT-BASED-ELECTRICAL-MOTOR-CONTROL-AND-MONITORING-6-2048.jpg)