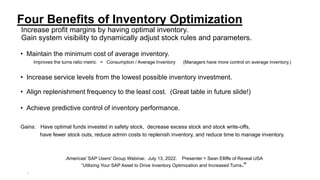

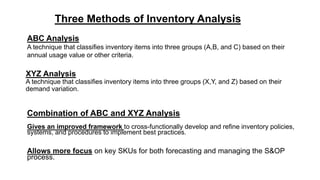

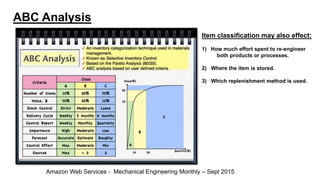

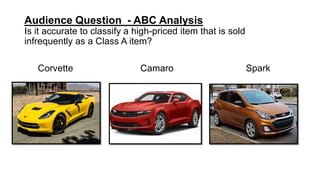

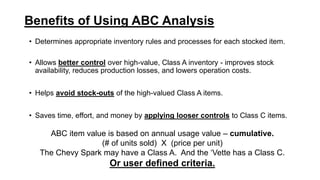

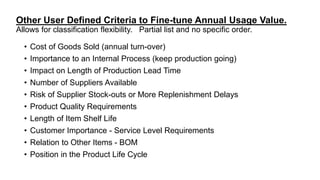

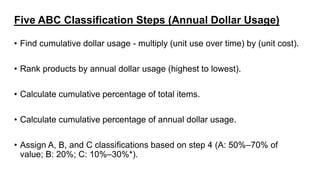

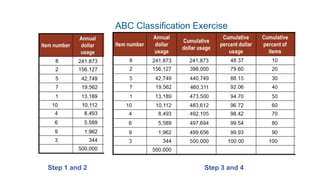

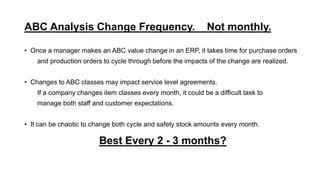

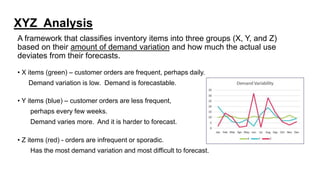

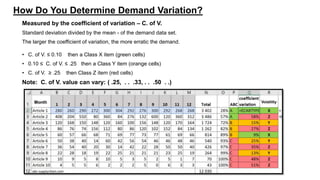

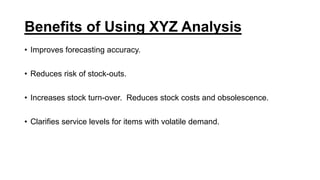

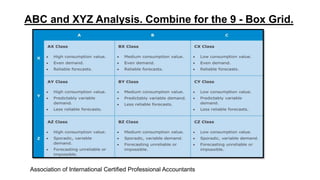

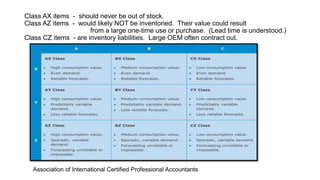

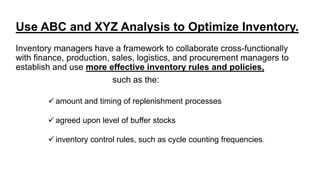

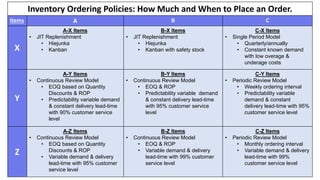

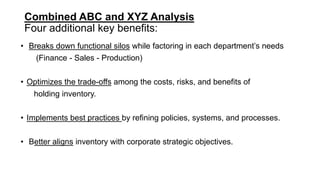

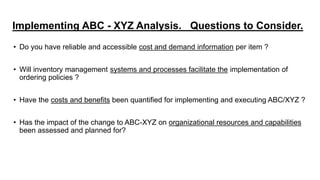

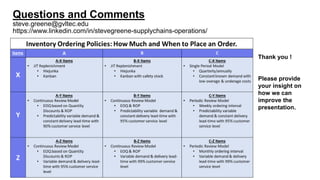

The document discusses inventory optimization through ABC-XYZ analysis, which classifies inventory items based on their usage value and demand variation to enhance efficiency and minimize costs. Key benefits include improved profit margins, visibility, service levels, and inventory control. It emphasizes the need for a collaborative approach across various departments to implement effective inventory management practices.