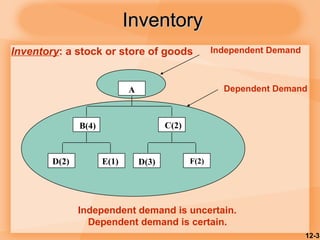

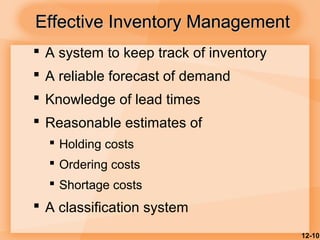

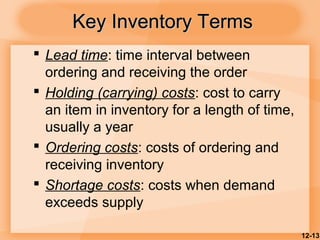

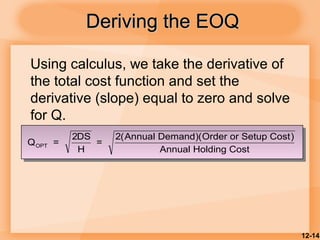

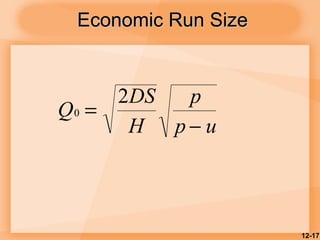

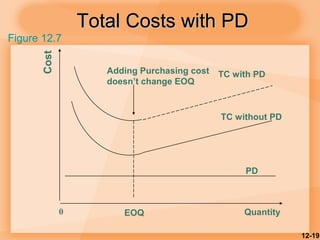

Inventory management involves determining the appropriate level and types of stocked goods. There are two types of demand: independent demand which is uncertain, and dependent demand which is certain. Effective inventory management requires tracking inventory levels, forecasting demand, and understanding costs like holding, ordering, and shortage costs. The economic order quantity (EOQ) model can be used to determine the optimal order quantity that minimizes total inventory costs. The reorder point is the level at which an item should be reordered, and safety stock is extra inventory held to protect against uncertain demand or lead times.