Embed presentation

Downloaded 11 times

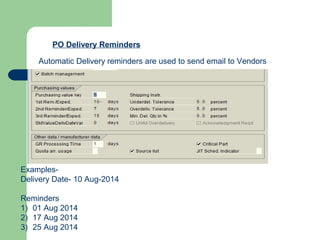

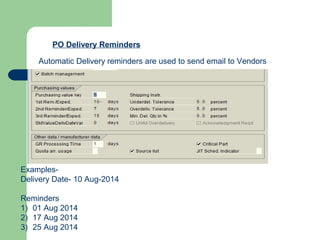

This document discusses inventory optimization steps that can be implemented with SAP, including standardizing materials, seasonal material planning, vendor managed inventory, repair and maintenance budget controlling, purchase order delivery reminders, alerts for stock levels, and purchase requisition return cycles. It provides details on how each step is configured and functions within the SAP system to help optimize inventory levels and management.