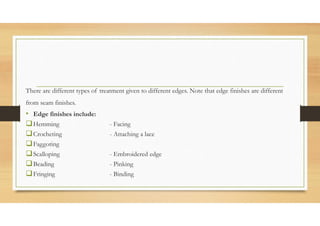

This document discusses different types of edge finishes used in clothing construction. It defines edge finishes as treatments given to raw edges of garments to make them look neat. Some common edge finishes mentioned include hemming, facings, bindings, and lacing. Hemming involves folding the edge twice and sewing it down. A facing involves attaching a duplicate layer of fabric to cover the raw edge. Binding uses a separate strip of fabric attached around edges. Lace can also be attached as an edge finish. Factors like the edge type and fabric are considered when choosing an edge finish.