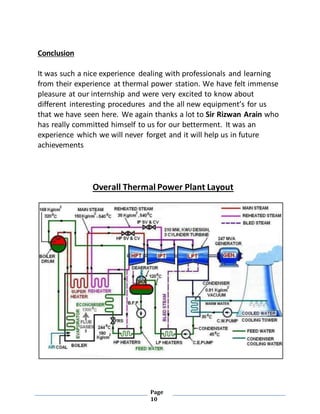

This document is a 14-day internship report submitted by Meer Muhammad to Sir Rizwan Arain about their time at the JPCL Jamshoro Thermal Power Station in Sindh, Pakistan. It provides an overview of the major mechanical components of the power station, including the boilers, steam turbines, condenser, feedwater pumps, cooling towers, fans, and flue gas stack. It concludes that the internship was a valuable learning experience that provided insight into the interesting procedures and equipment used at a thermal power plant.