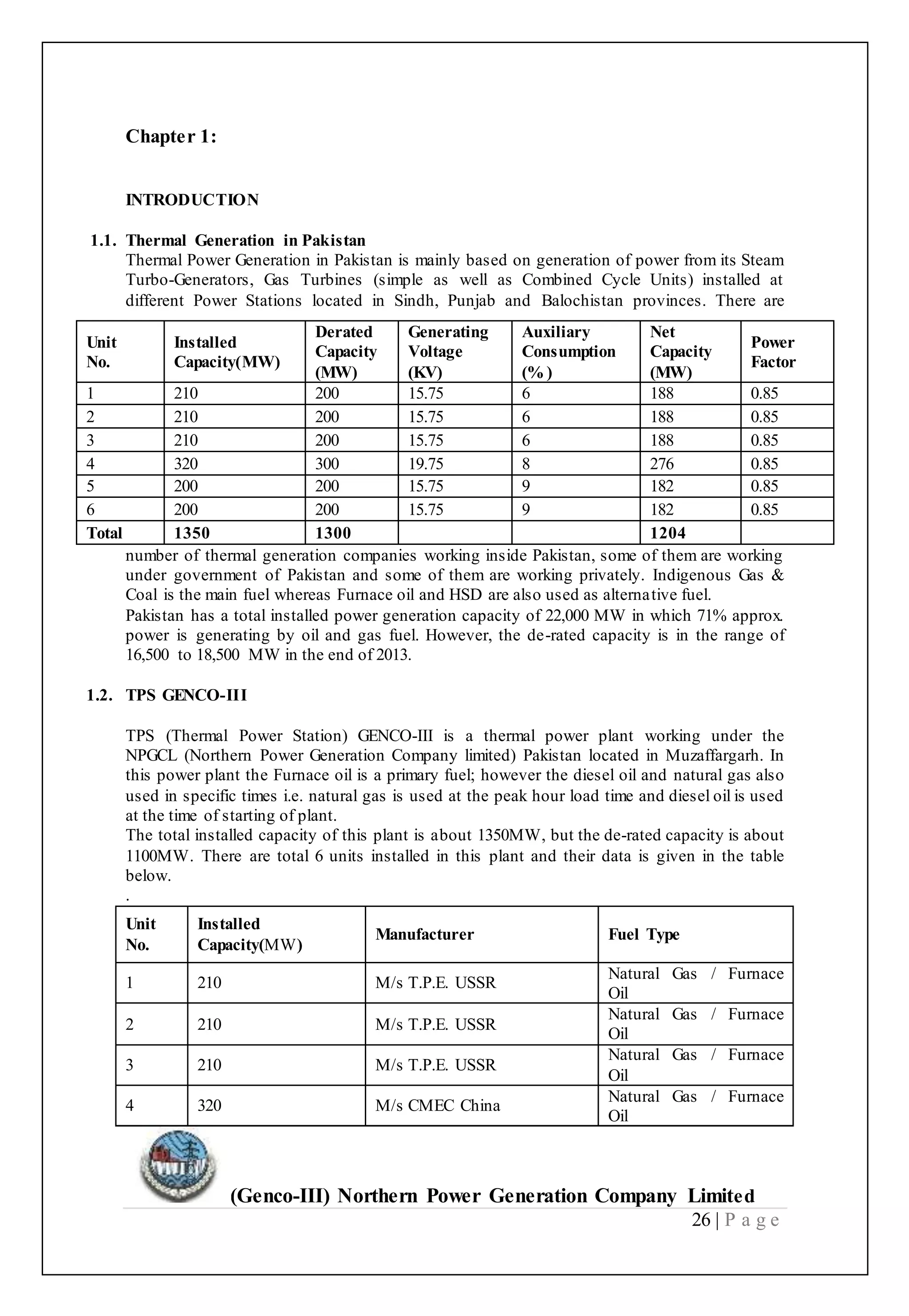

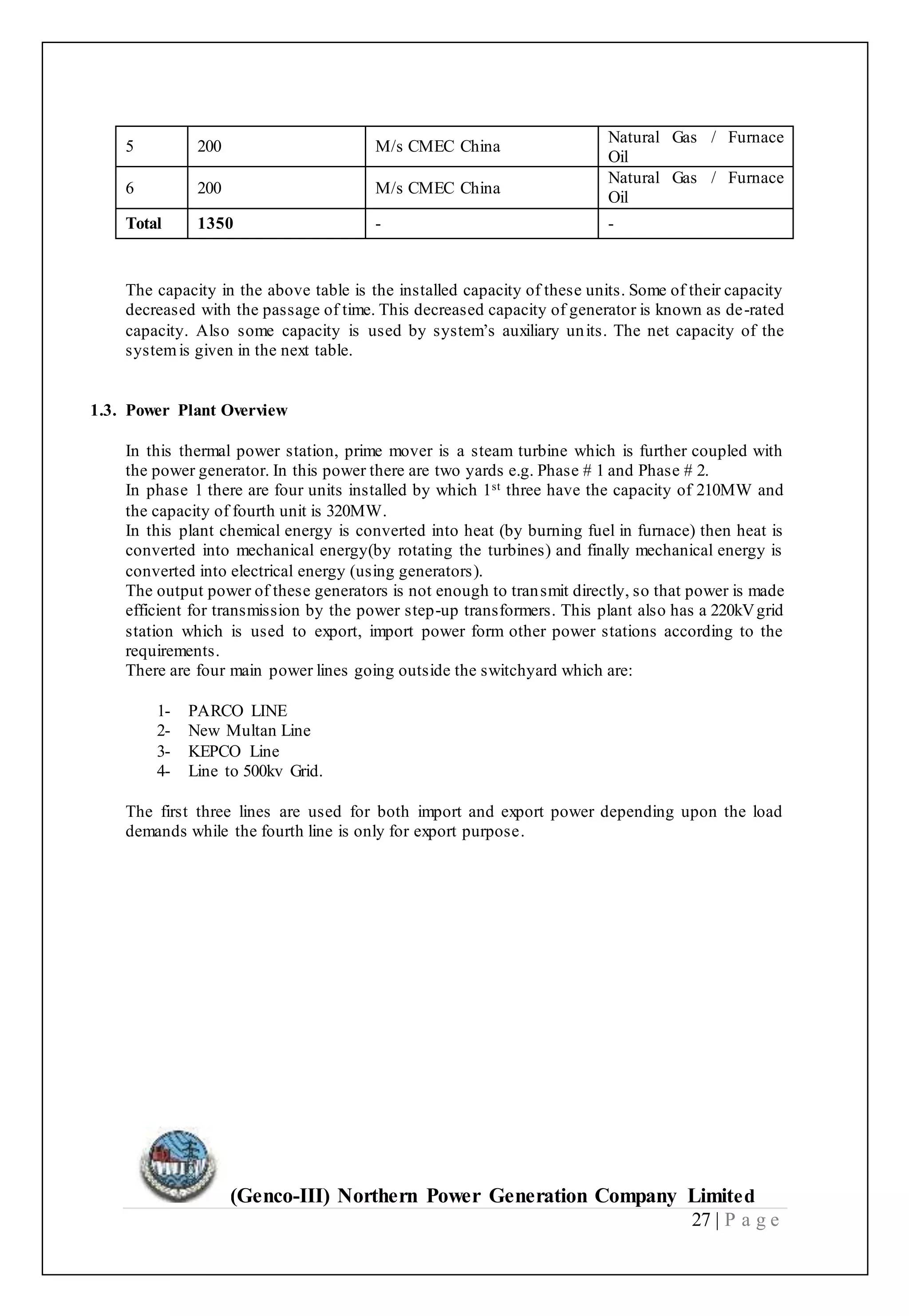

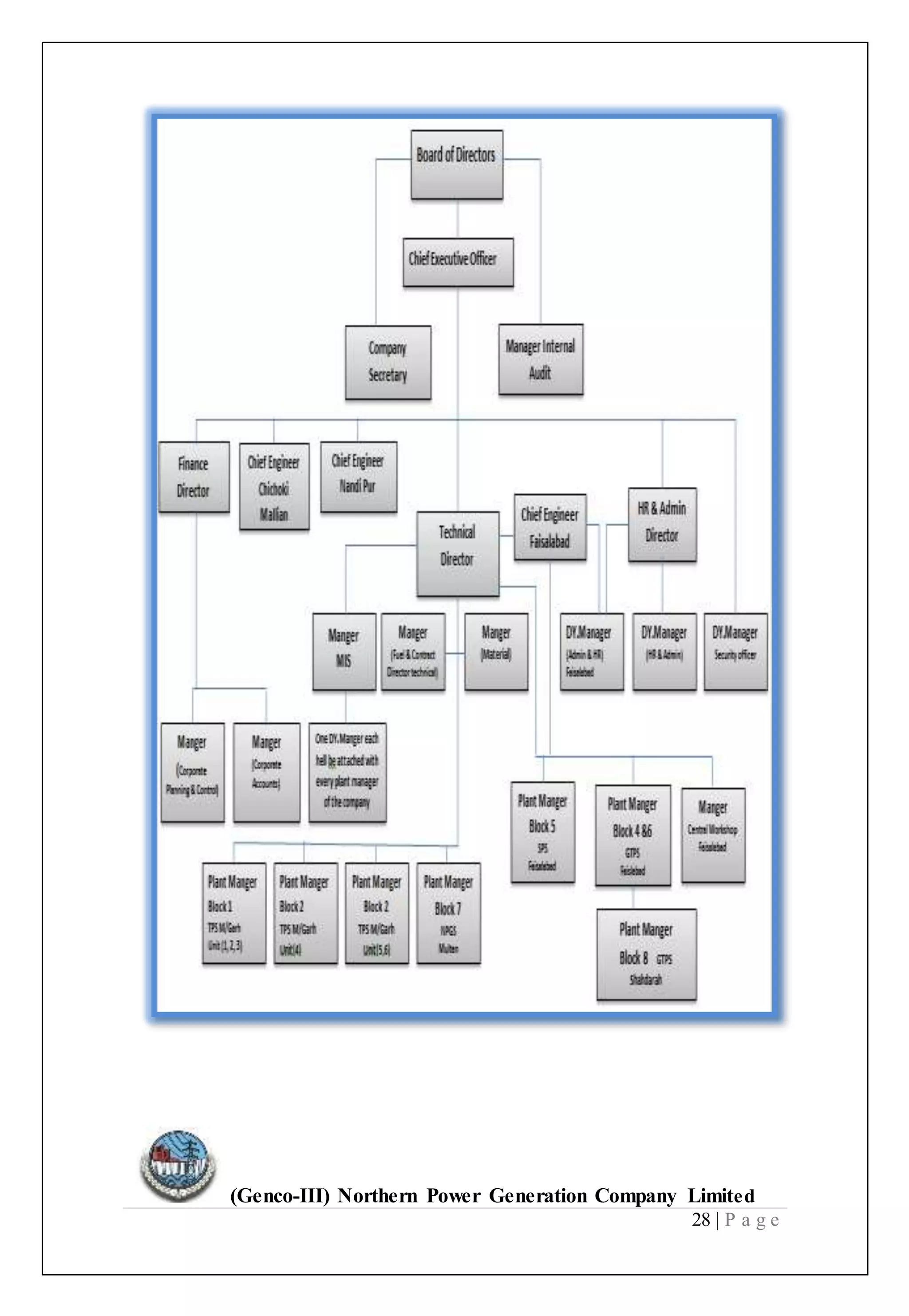

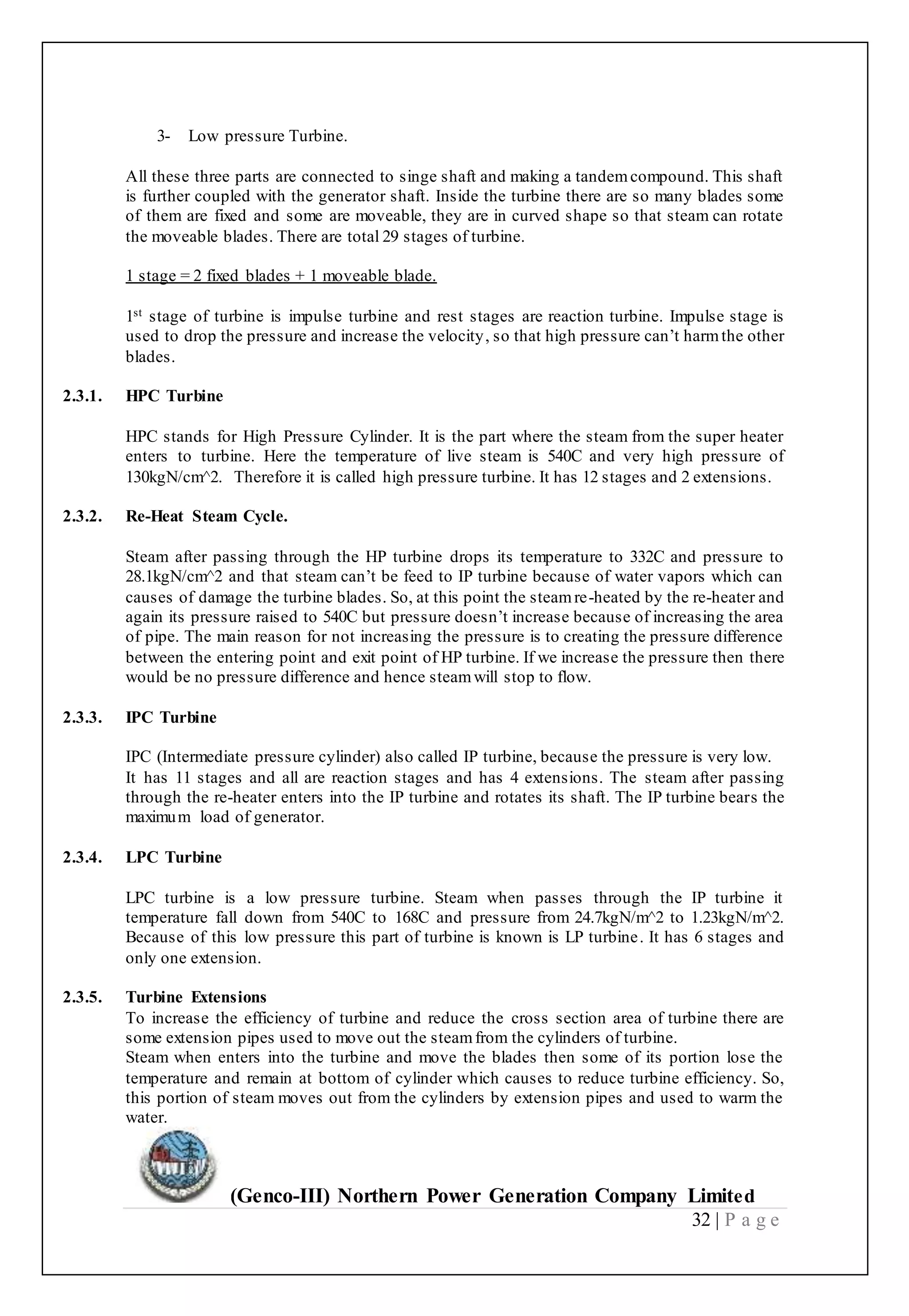

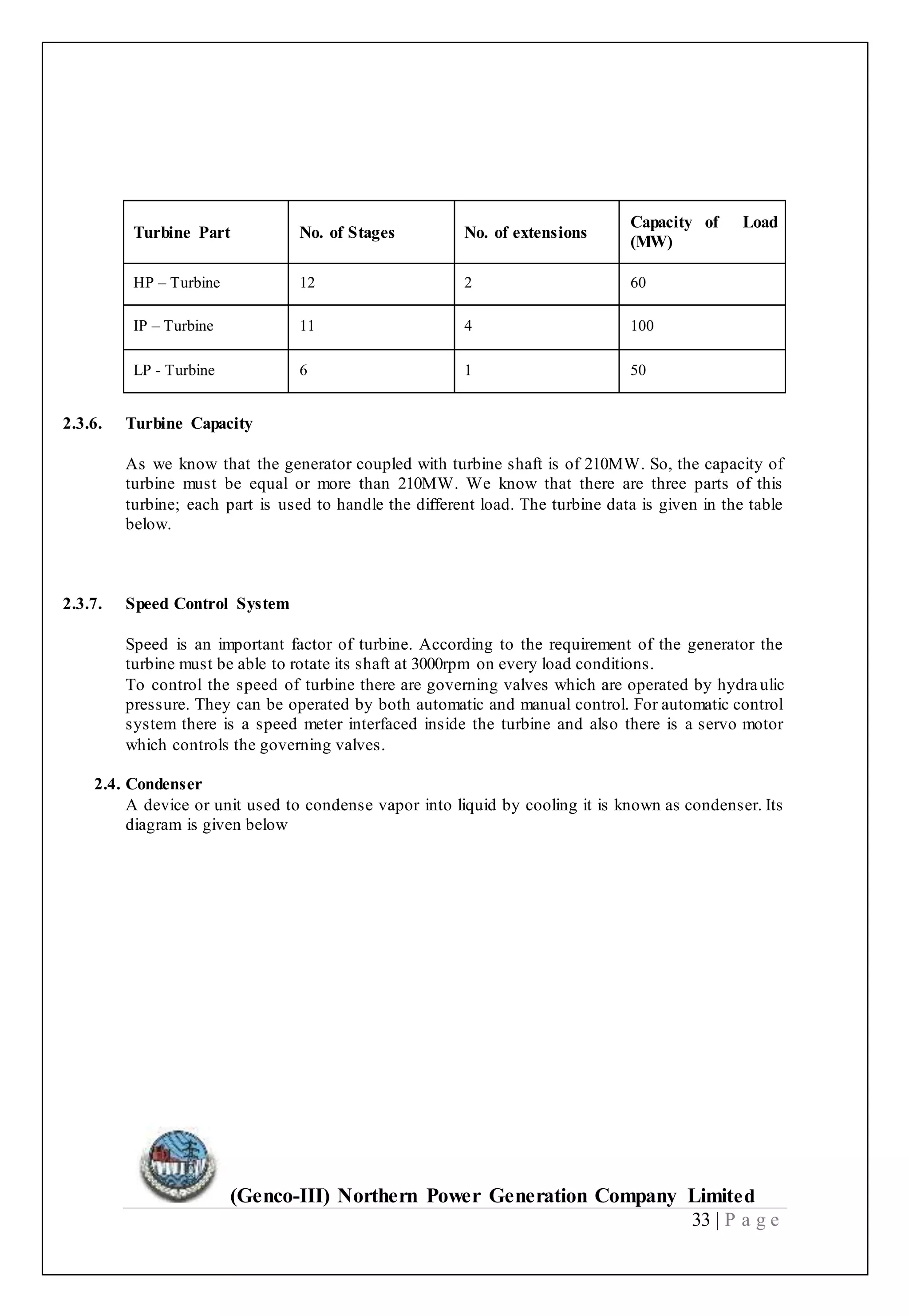

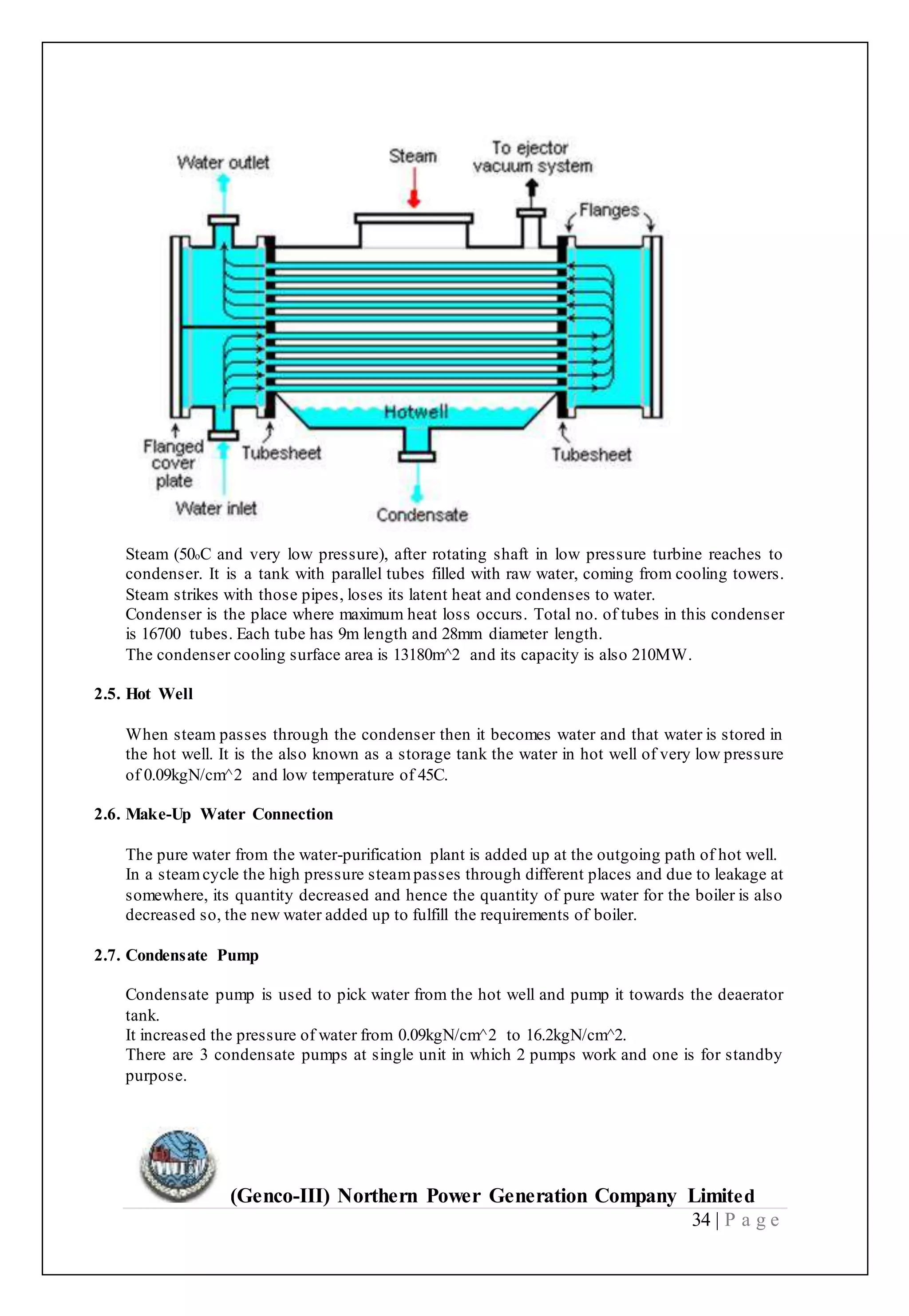

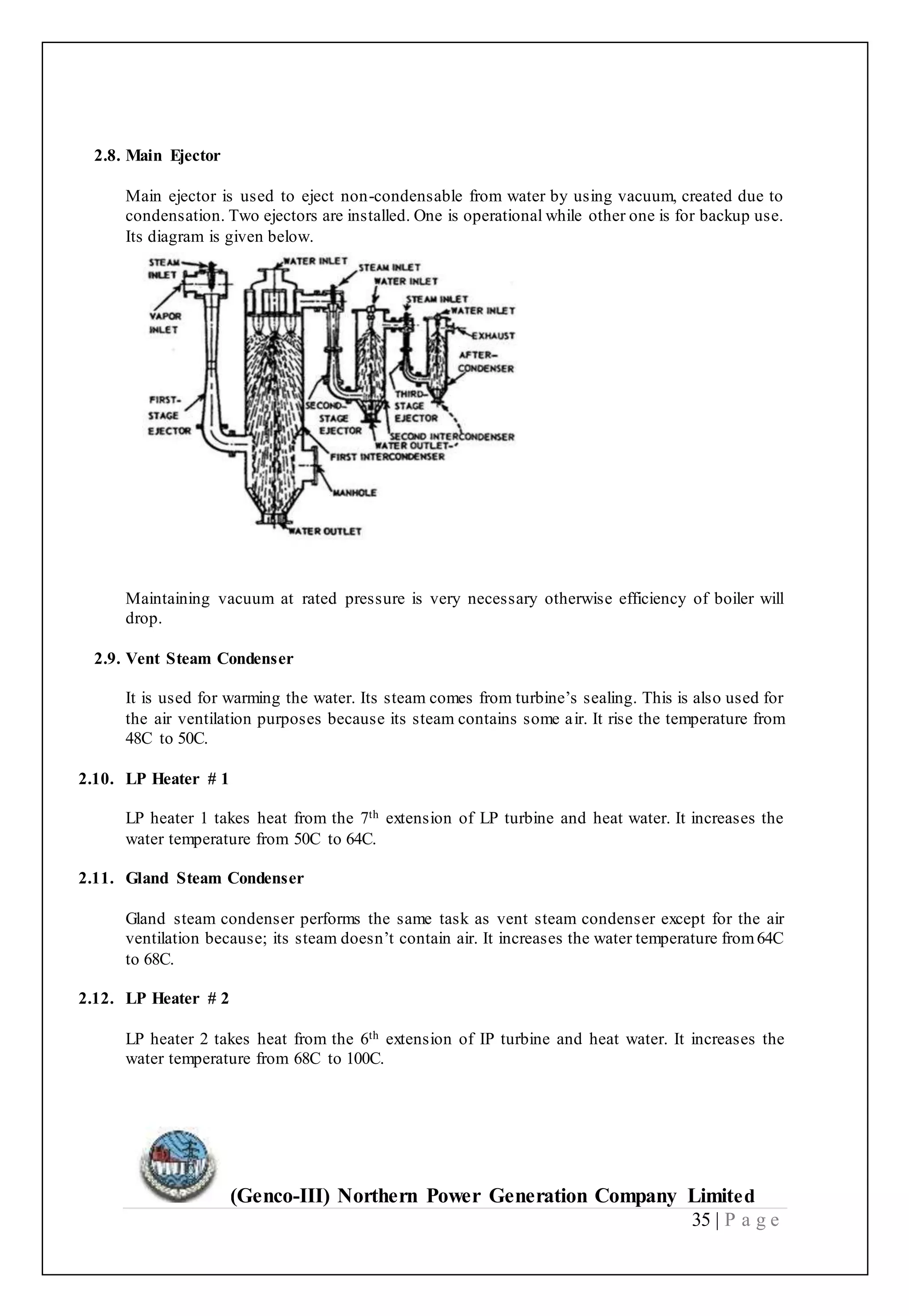

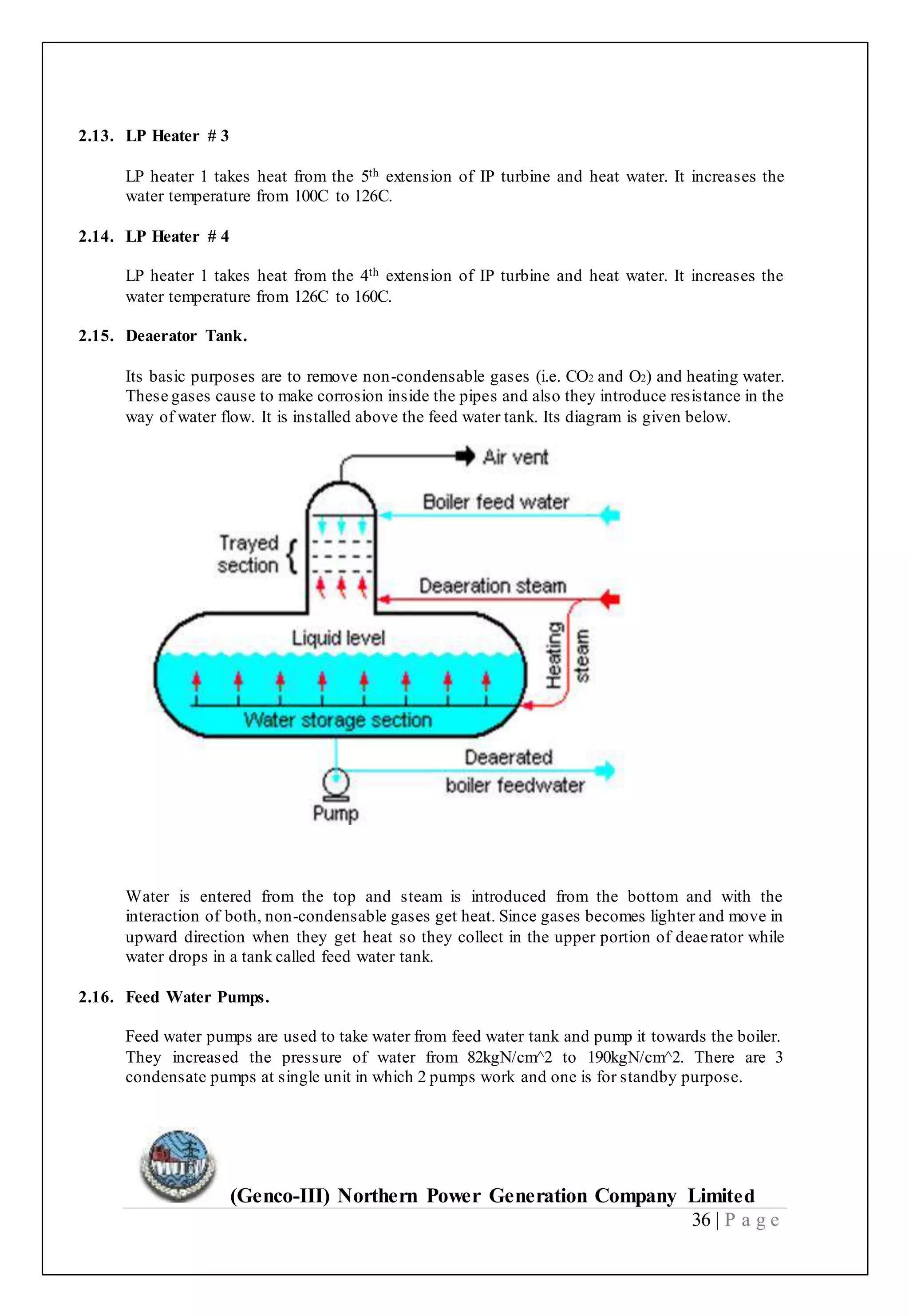

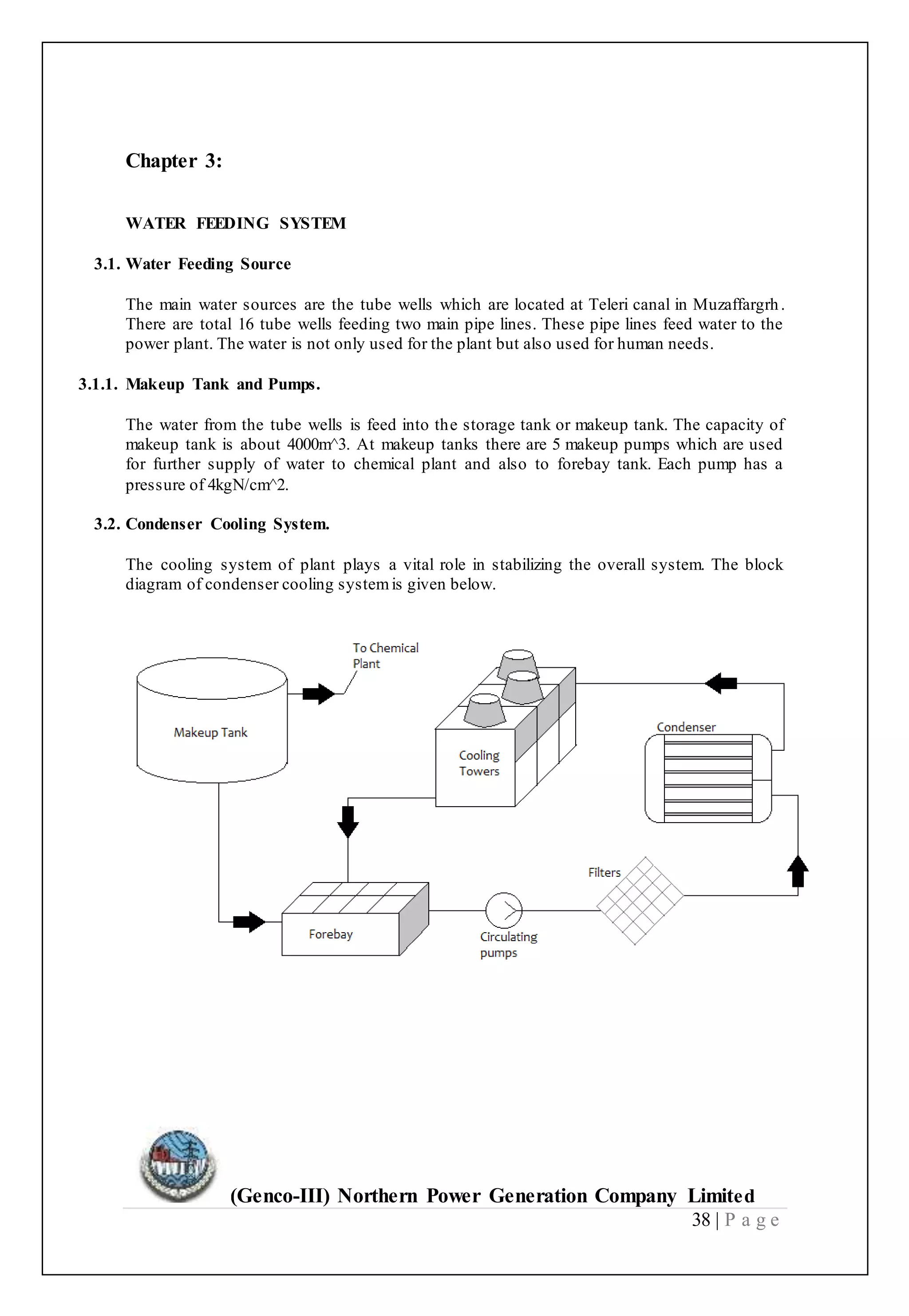

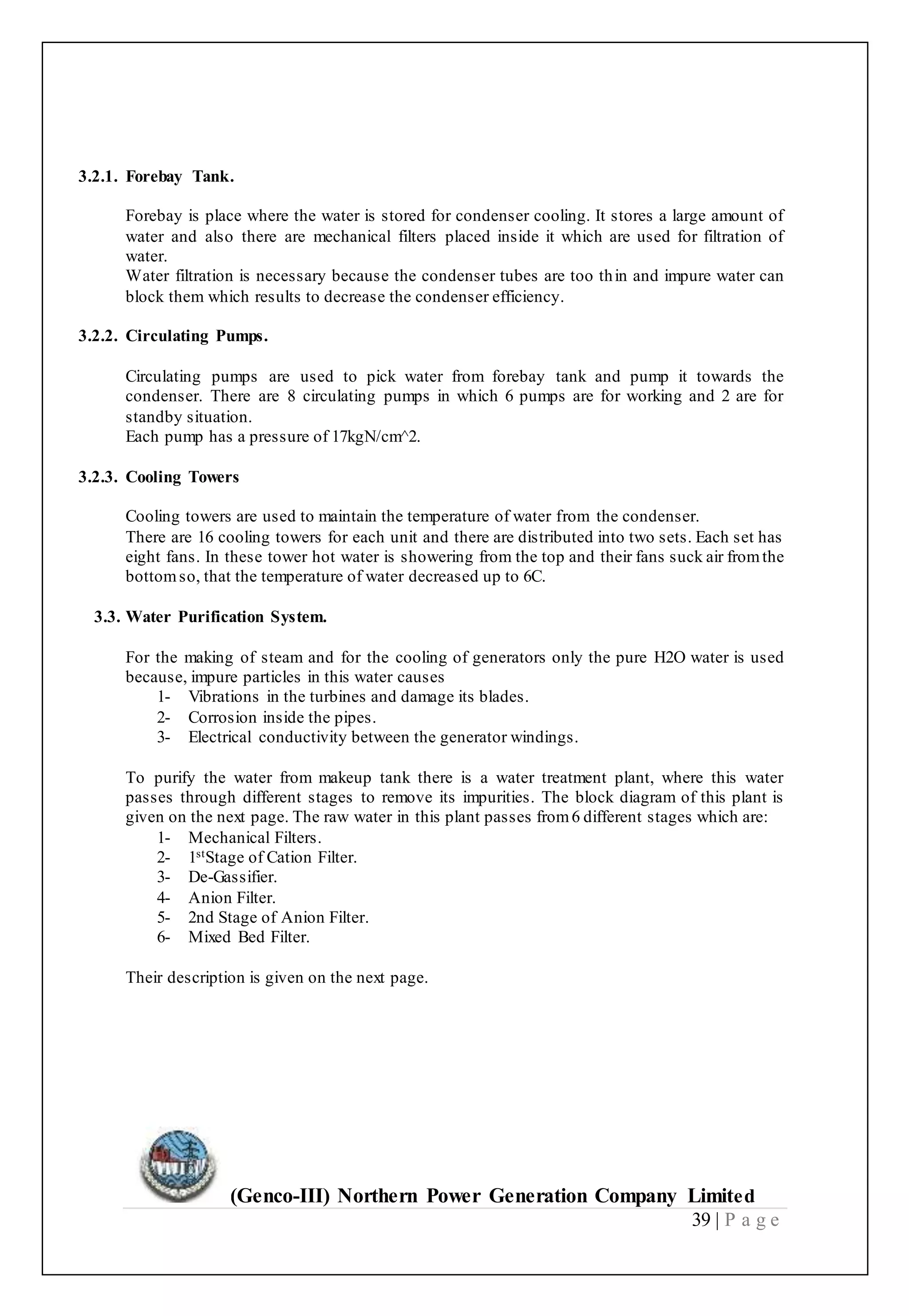

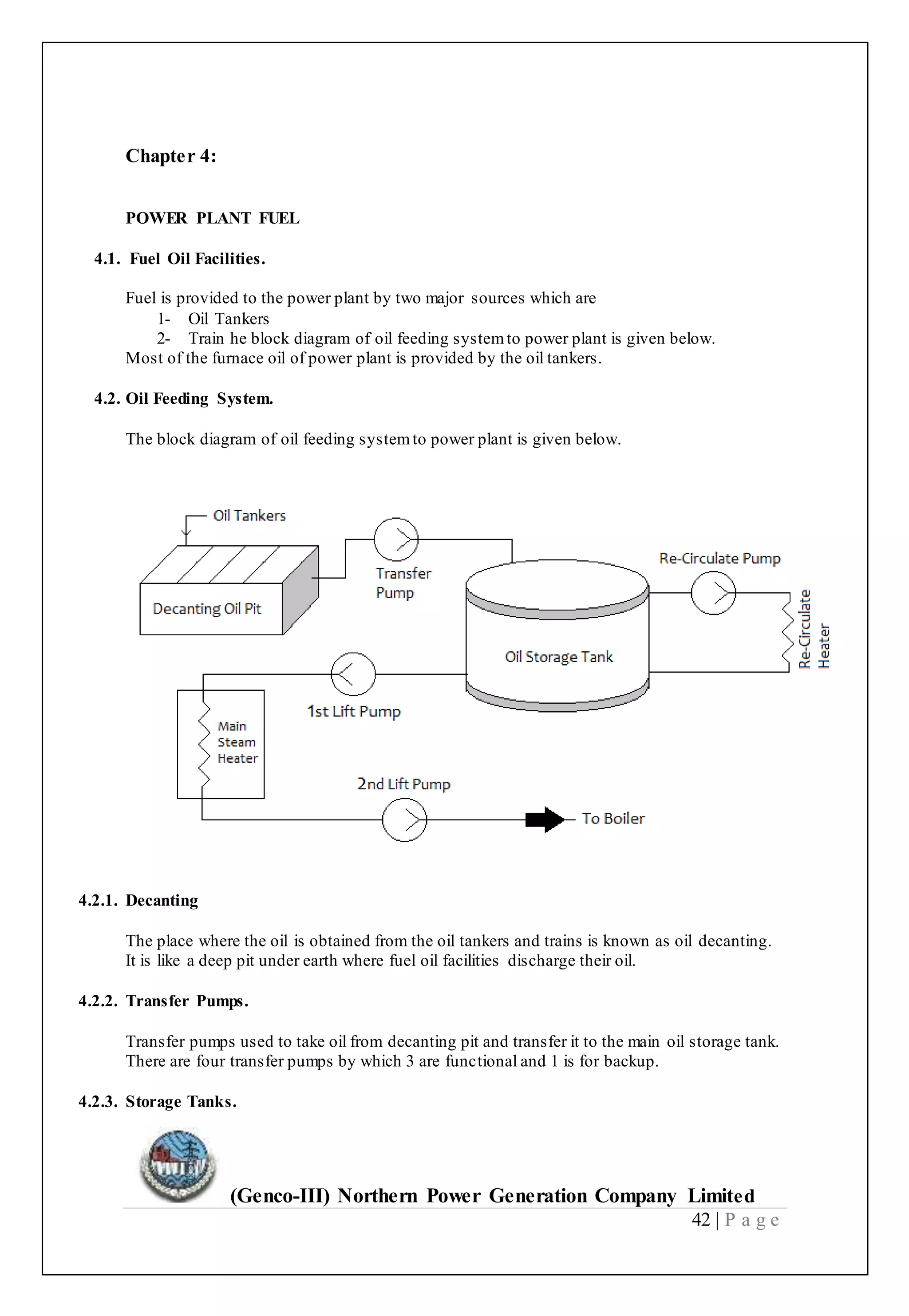

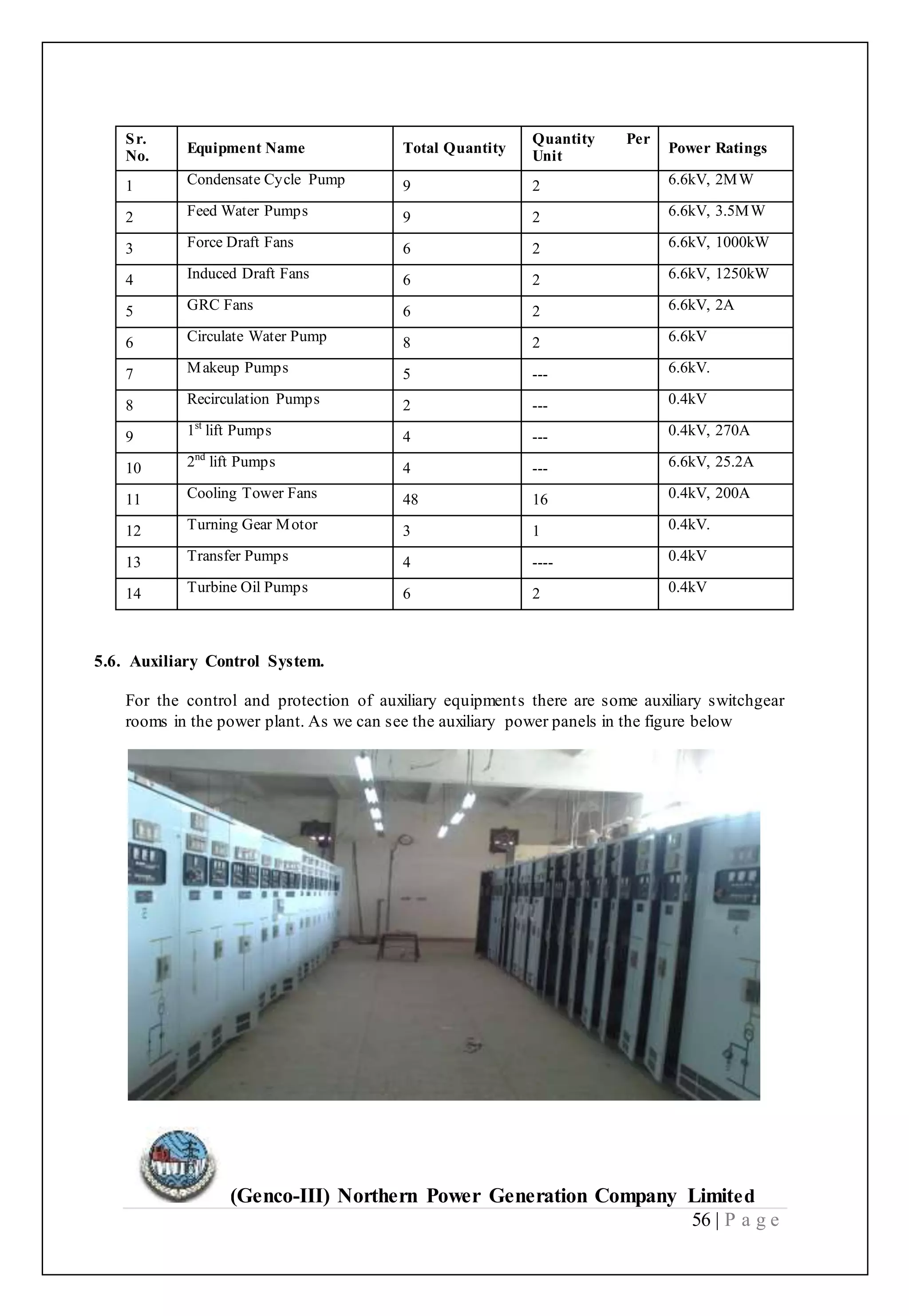

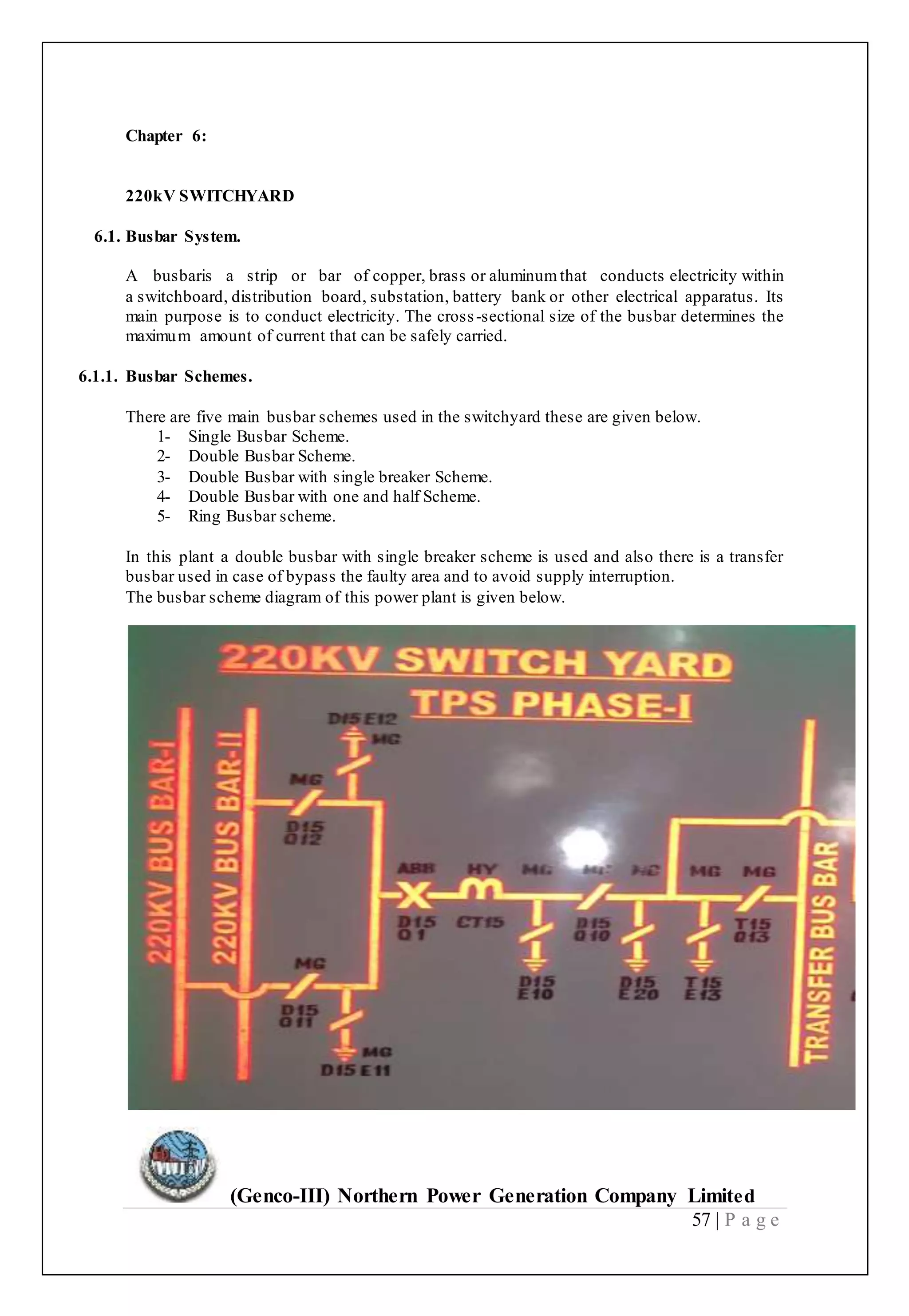

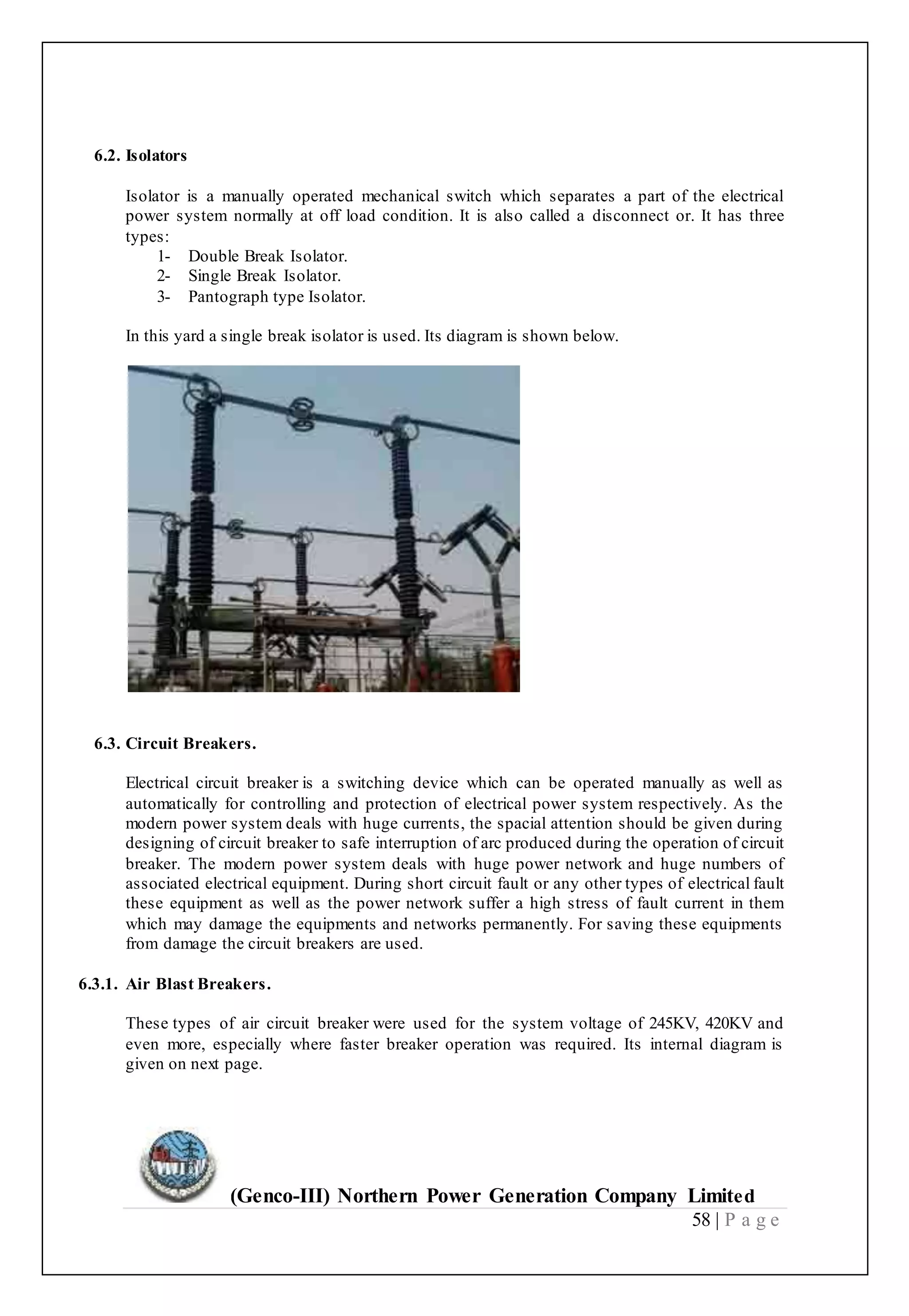

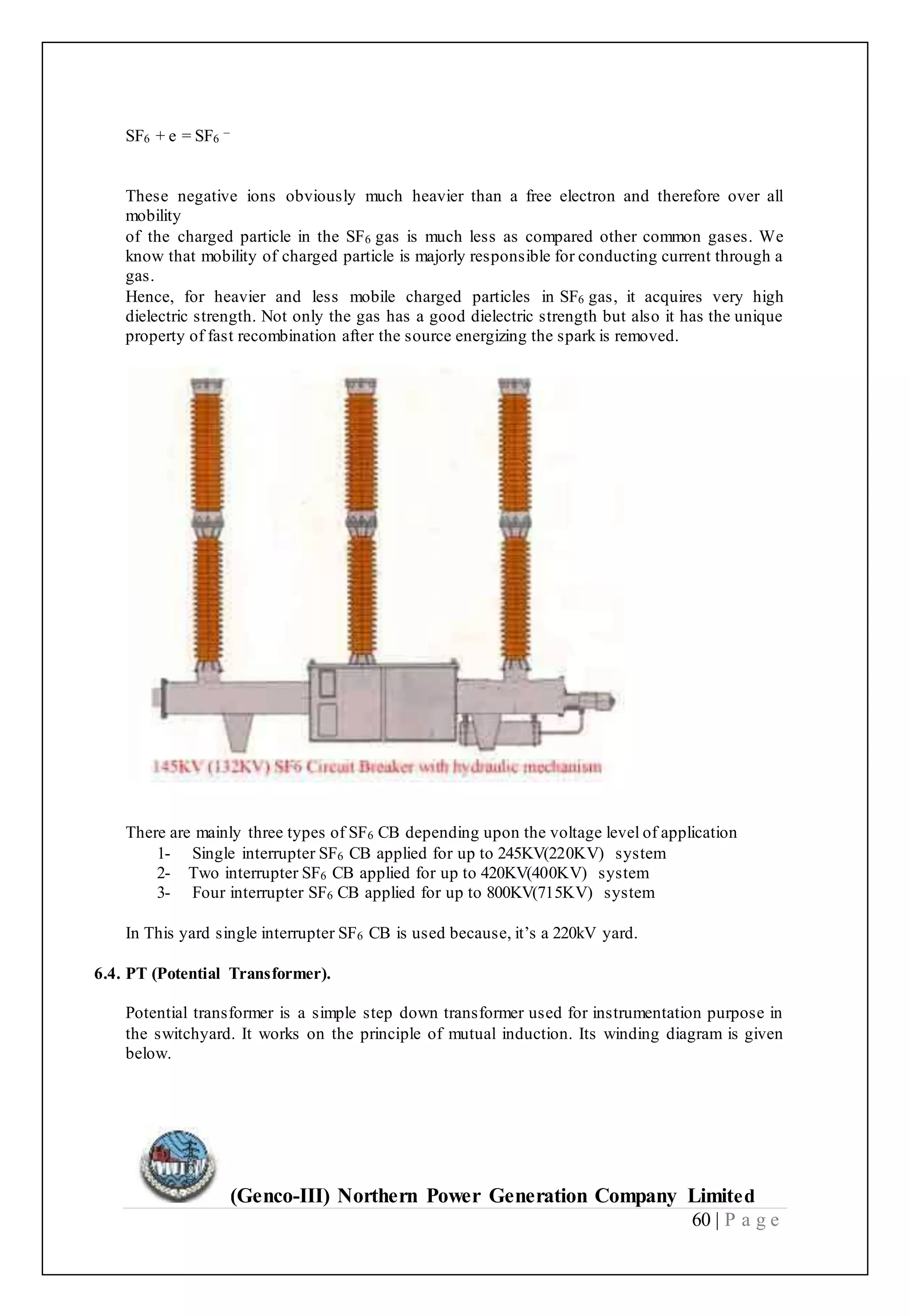

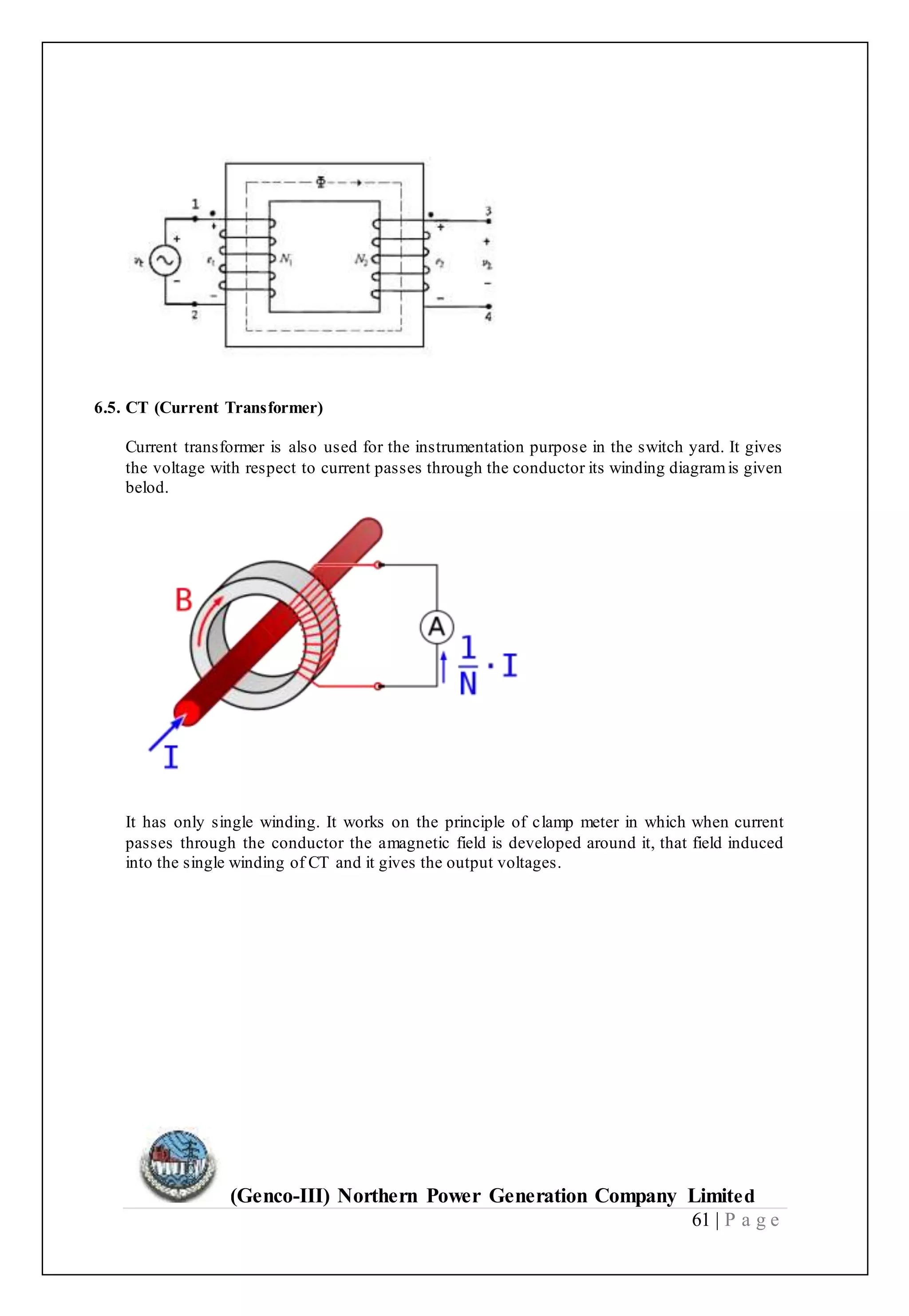

This document provides an overview of the (Genco-III) Northern Power Generation Company Limited in Pakistan. It discusses the company's 6 power generation units with a total capacity of 1,370MW, fueled by furnace oil. The report outlines the key components of the thermal power plant, including the boiler, steam turbine, condenser, water feeding system, fuel facilities, electricity generation equipment, and 220kV switchyard. It also includes sections on the objectives, goals and operations of the power plant.