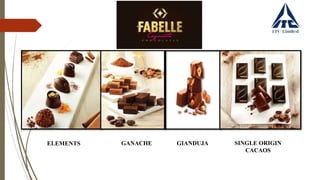

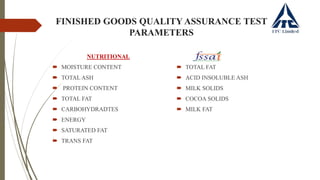

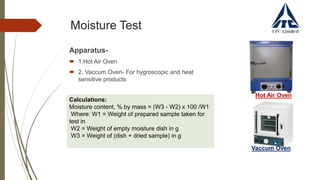

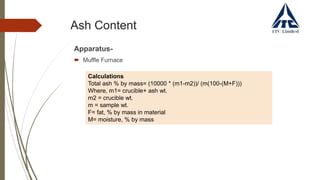

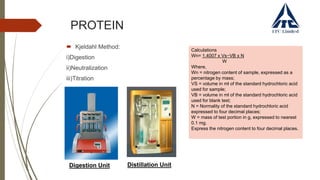

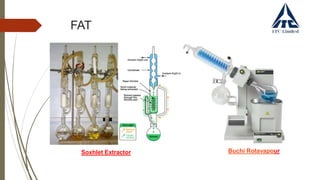

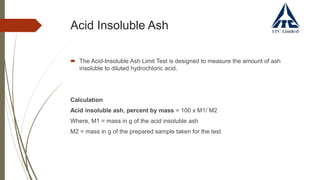

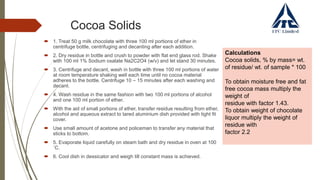

The document outlines the internship presentation at ITC Life Science & Technology Centre in Bengaluru, detailing its R&D functions, quality assurance processes, and specific tests conducted on raw materials and finished products. Key parameters for testing include nutritional content, moisture, and ash content, among others, using various laboratory techniques and apparatus. The internship provided insights into quality determination and hands-on experience with advanced testing equipment.